Precision Injection Molding Service

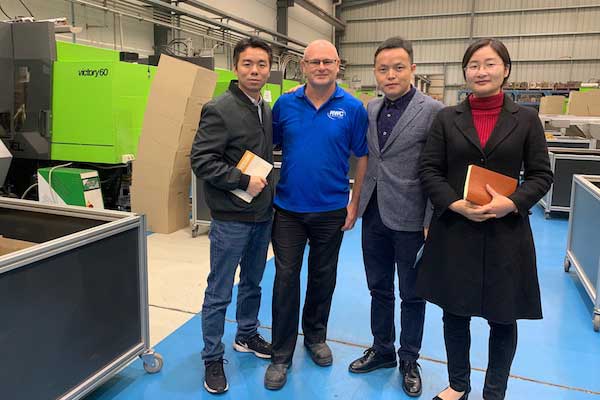

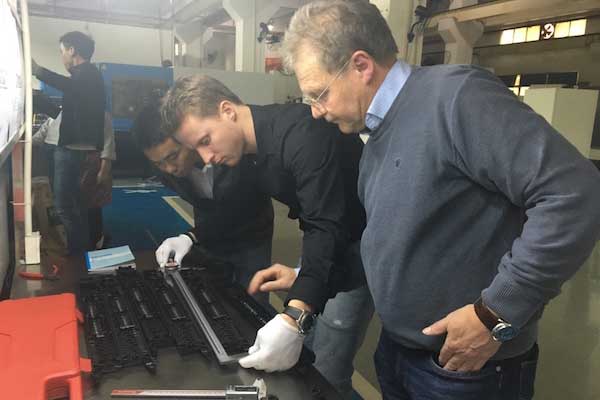

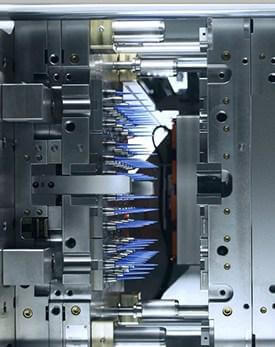

Mold design for precision injection molding is one of the most complex and expensive methods of plastic molding. The Holly Engineering Department has an excellent technical team with 14 experienced engineers who can quickly design drawings for products or standard mold structures and guide production. 80% of our engineers have more than 10 years of experience in the injection molding industry. The perfect combination of design and manufacturing technology and practical experience is the guarantee of mold accuracy.

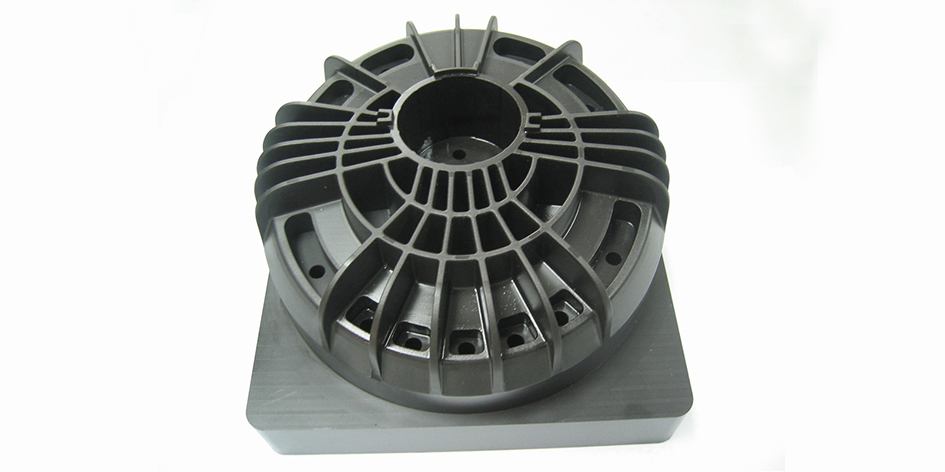

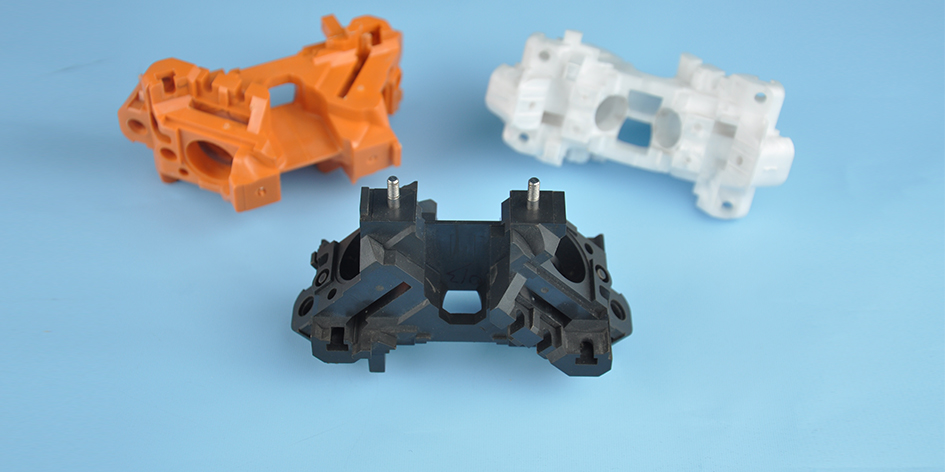

Precision Injection Molding Parts

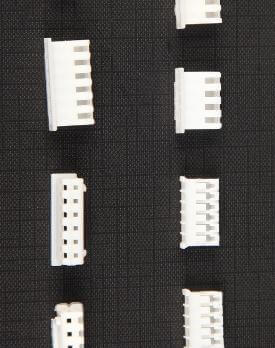

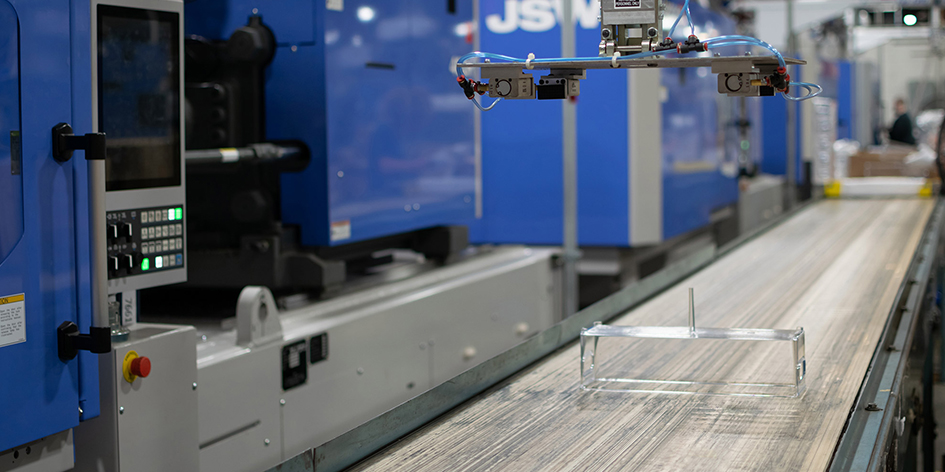

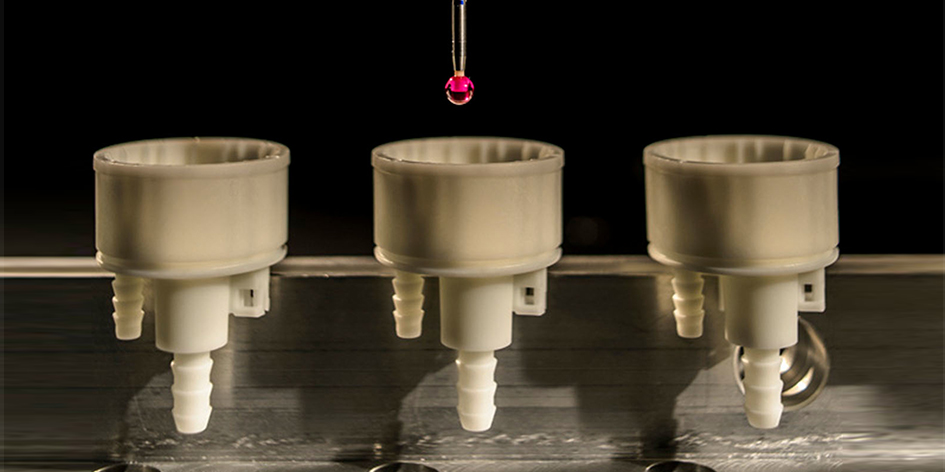

Precision injection molding is a method of producing injection molds with a dimensional accuracy of 0.01mm or less, usually between 0.02-0.005mm. Holly has a precision injection molding workshop and a dust-free workshop. The machine tonnage ranges from 60 tons to 200 tons to ensure the quality of the products in the production process. Mainly used in aerospace, auto parts, medical parts, gear parts, electrical connectors, precision instruments, sports equipment, testing tools and other industrial and civilian products.

China High Precision Injection Molding Manufacturer FAQ

Precision Injection Molding: Ultimate FAQ Guide

For precision injection molding, Holly combines expertise in design for manufacturability, from concept to mass production, and has extensive experience in comprehensive analysis and test evaluation and verification, designing and manufacturing lighter and more durable precision parts.

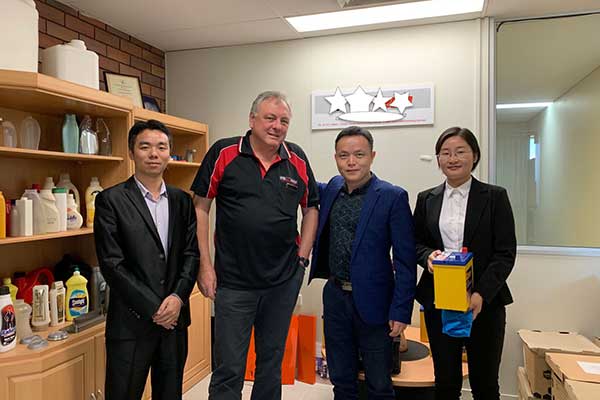

For more than 20 years, Holly has been serving the needs of global customers for precision injection molds. As a trusted partner of leading brands, Holly’s precision injection molding technology enables the company to produce parts that meet consumer needs with high quality and efficiency, thereby maintaining competitiveness. Please contact us to customize your precision injection mold. The Holly project engineer will supervise the whole process and provide regular updates and delivery.

As a professional precision injection molding manufacturer with 24 years of experience. Holly has paid 100% enthusiasm for you.

Here is a list of frequently asked questions about precision injection molding.

1. What is precision injection molding?

Precision injection molding refers to the high dimensional accuracy of injection molded products. So using a general injection molding machine, the conventional injection molding process can hardly meet the requirements of an injection molding method.

2. What are the characteristics of precision injection molding?

The characteristics of precision injection molding are as follows:

- The parts have high dimensional accuracy and small tolerances, that is, they have high-precision dimensional limits.

- The product has high weight repeatability and good dimensional stability by day, month and year.

- The mold material is good, the foot rigidity is good, the cavity size accuracy is high, the smoothness is high, and the positioning accuracy between the templates is high.

- Replace the traditional injection molding machine with a precision injection molding machine.

- Using precision injection molding process.

- Choose materials suitable for high-precision injection molding.

3. In what ways do we need to control the accuracy of the product?

The areas where we need to control product accuracy are as follows:

This requires strict control of four major factors including material selection, mold design, injection molding process, and the technical level of operators.

4. What are the requirements of precision injection molding for injection molding machines?

The requirements of precision injection molding for injection molding machines are as follows:

Precision injection molding machines require product dimensional accuracy generally between 0.01 ~ 0.001mm. Many precision injection molding machines also require high injection pressure and high injection speed.

The clamping system is required to have sufficient rigidity and high enough clamping accuracy. Clamping accuracy refers to the uniformity, adjustability, stability, repeatability of the clamping force, and high accuracy of the clamping position.

Pressure, flow, temperature and measurement need to be precisely controlled to the corresponding accuracy. The use of multi-stage or stepless injection ensures the reproducibility of the molding process and the repeatability of product dimensions.

5. What are the factors that affect the dimensional accuracy of precision plastic products?

The factors affecting the dimensional accuracy of precision plastic products are as follows:

- Mold accuracy;

- Form shrinkage rate;

- Conditions in which the product is used, such as temperature, humidity, and fluctuation range

6. What are the selection principles of injection precision molding materials?

The selection principles of injection molding precision molding materials are as follows:

- High mechanical strength

- Good dimensional stability

- Good creep resistance

- Wide environmental adaptability

7. What are the commonly used materials for precision injection molding?

- POM and carbon fiber reinforced (CF) or glass fiber reinforced (GF) materials have good creep resistance, fatigue resistance, weather resistance and dielectric properties, and are not easy to burn. Add lubricant, easy to demold

- PBT reinforced polyester with short molding time: PBT≤POM≈PA66≤PA6.

- Computer and GFPC. Features: Good abrasion resistance, enhanced rigidity after strengthening, good dimensional stability, good weather resistance, good flame retardancy, and good processing performance.

8. In injection molding, what are the factors that affect the shrinkage rate?

Thermal shrinkage, phase change shrinkage, rotational shrinkage, and compression shrinkage are four factors that cause shrinkage.

9. What are the characteristics of precision injection molds?

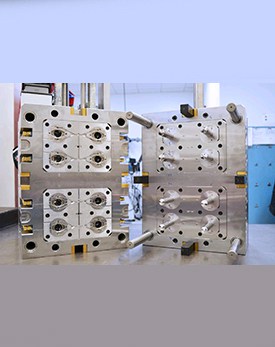

The characteristics of precision injection molds are as follows:

The accuracy of the mold mainly depends on whether the dimensional accuracy of the mold cavity, the positioning accuracy of the cavity or the accuracy of the parting surface meet the requirements. Generally, the dimensional tolerance of precision injection molds should be controlled within 1/3 of the product dimensional tolerance.

Machinability and rigidity. In the mold structure design, the number of cavities should not be too much, and the bottom plate, support plate, and under high pressure and high temperatures, cavity walls should be thick to prevent severe elastic deformation of the parts.

A mold should have few cavities, fewer runners, and a high finish when the product is demolded, so that it is conducive to demolding. The material of the mold is precise, and alloy steel with high mechanical strength is selected.

The materials of the mold cavity and runners should undergo strict heat treatment, and the materials with high hardness (molded parts should reach about HRC52), good wear resistance and strong corrosion resistance should be selected.

10. What is the reason why the precision injection molding machine must be high pressure?

The reasons why precision injection molding machines must withstand high pressure are as follows:

1) A precision product’s shrinkage rate is the most obvious factor affecting precision and quality. Almost no molding shrinkage occurs when the injection pressure reaches 392MPa. In this case, the accuracy of the product is only affected by mold control or the environment. According to the experimental results, the mechanical strength of the material increases by 3% * 33% when the injection pressure is increased from 98MPa to 392MPa.

2) It can reduce the wall thickness of precision products and increase the forming length. Taking a computer as an example, a product with a wall thickness of 0.2 to 0.8 mm can be molded with an injection molding pressure of 177 MPA on an ordinary machine, while a product with a thickness of 0.15 to 0.6 mm can be molded with a precision machine with an injection pressure of 392 MPA. The ultra-high pressure injection molding machine can be manufactured for a longer time than the product.

3) Increasing the injection pressure can fully promote the effect of injection speed. To achieve the rated injection rate, there are only two methods: one is to increase the maximum injection pressure of the system; The second is to improve the screw parameters and the ratio of length to diameter. The injection speed of the precision injection molding machine is high.

11. What are the characteristics of precision injection molding machines in terms of control?

- High requirements for the repeatability (reproducibility) of injection molding parameters; Multi-stage injection feedback control

- Multi-level position control;

- Multi-level speed control;

- Multi-level pressure holding control;

- Multi-level back pressure control;

- Multi-stage screw speed control.

12. In the design of plastic precision injection molding, in addition to the general mold design, what else needs special consideration?

- In order to obtain products with required dimensional tolerances, appropriate tools should be considered for dimensional tolerances.

- Prevent shrinkage fluctuation by preventing shrinkage formation.

- Take care to avoid deformation.

- Consider preventing demoulding deformation.

- Minimize the molding error.

- Consider preventing fluctuations in mold accuracy 6) Consider preventing fluctuations in mold accuracy.

13. In the design of precision injection molding, what are the main factors that affect the molding shrinkage rate?

- Resin pressure,

- Resin temperature

- Mold temperature

- The cross-sectional area of the door,

- Injection time

- Cooling time

- Product wall thickness

- Enhanced pot-containing material,

- Orientation,

- Injection speed.

These effects vary with the project, such as resin and molding conditions.

14. In precision injection molding design, how to prevent molding deformation?

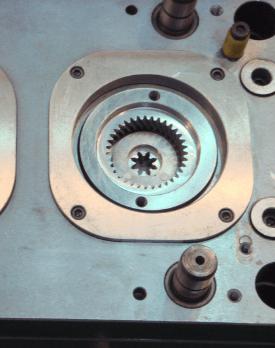

The forming deformation is caused by internal stress in the case of uneven shrinkage, so it is necessary to prevent uneven shrinkage. For circular gears with a hole in the centre of the gear, A door must be placed in the centre. However, when the shrinkage ratio between the flow direction and the vertical direction of the resin differs greatly, an ellipse will occur.

When higher roundness accuracy is required, a 3-point or 6-point gate should be set. However, pay full attention to the balance of the door. When using side gates, three-point gates will increase the inner diameter of the cylindrical product. In the case that the outer surface and end surface are not allowed to have gate marks, better results can be achieved by using fewer inner multi-point gates.

15. How to prevent demoulding deformation in precision injection molding design?

Precision products are generally small, with thin walls, and some have many thin ribs. The design of chess must take into account that the pieces will not be deformed and can be removed appropriately. Suitable for resins with low shrinkage.

When the molding pressure is high, pay attention to the products that tend to stay in the mold cavity. When molding gears with resins with small shrinkage holes, the mold cavity of the gear parts is best designed on the ejector side template. When using the ejector pin, pay attention to the number of ejector pins and the position of the ejection pressure.

Gears with holes need a core pin, which should be set on the ejection side template to facilitate parallel ejection during the ejection process. For horn products, punching templates can be used for ejection to prevent deformation. Generally speaking, the draft angle of precision products is small. Mirror processing and grinding in the direction of the drawing die are necessary to reduce the demolding force. The block core that is convenient for grinding should be set in the direction of the die.

16. How to reduce mold manufacturing errors?

In order to maintain the precision of the mold, high wear resistance is required, quenching is required this. Through grinder and EDM machine, the precision of the quenching die can reach 0.01 mm. In the process of EDM machining the red mold, attention should be paid to the increase of electrode wear.

17. How to reduce the error of mold accuracy?

Ensure the positioning of the sliding parts in each cycle, it is necessary to prevent fluctuations in mold accuracy. In order to maintain the accuracy of the sliding parts, the sliding parts should be worn by fire. The sliding part of the side core shall be equipped with a positioning part.

18. What should be paid attention to in the design of precision injection molds?

In the design of precision injection molds, in addition to general mold design considerations, the following items should also be specially considered.

- In order to obtain the required dimensional tolerances of the product, appropriate mold dimensional tolerances need to be considered.

- Prevent the formation of shrinkage fluctuations.

- Avoid forming deformation.

- Avoid demoulding deformation.

- Minimize molding errors as much as possible.

- Prevent fluctuations in mold accuracy.

- Maintain mold accuracy.

19. What are the common molding defects in precision injection molding?

- Short ball

- Splashing flash

- Surface pores

- Flow marks

- Silver wire

- Welding marks

- Black stripes and burnt

- Bubble

- Cracking and albinism

- Bending deformation

- Mold bonding

- Shrinkage deformation

- Vacuum hole

20. What should I do when injection molding flashes appear on precision products during the precision injection molding process?

- When the clamping force is insufficient, it is necessary to use a larger injection molding machine.

- When the pinhole or guide pin of the mold is severely worn, repairs should be done by machining.

- When there are foreign objects and impurities on the closed surface of the mold, it should be cleaned.

- If mold temperatures or injection pressures are too high, it should be reduced appropriately.

21. What should I do when welding marks appear on precision products during precision injection molding?

- When the melting temperature of the material and mold is too low, to increase the temperature of the cylinder and the mold.

- Improper setting of gate position, the position of the door should change.

- If the raw material has high volatile content or poor mold exhaust, remove volatile substances in raw materials and improve mold exhaust system.

- The injection speed is too slow, it should be speeded up appropriately.

- If the mold has no cold material hole, the cold feed hole should be added.

- There are foreign bodies and impurities on the surface of the cavity, it should be cleaned.

- If the design of the pouring system is unreasonable, the filling performance of the gating system should be improved to make the melt flow smoothly in the cavity.