Professional 3D Printing Manufacturer from China

Holly provides high-precision 3D printing services for sectors such as automotive, electronics, medical, and industrial equipment. We use advanced FDM, SLA, SLS, and SLM technology and offer more than 75 materials to create functional and saleable products. Our equipment achieves tolerances of ±0.1-0.2 mm, with a product defect rate of less than 0.03% over the past five years. We also provide free mold design analysis and part optimization before mold processing for production efficiency and quality assurance.

Our 3D printing service supports a wide range of materials including plastics, metals, and elastomers in order to produce your 3D model into high-performance components. We have also various options for post-processing to enhance the surface finish as well as the mechanical properties.

At Holly, we are dedicated to delivering low-cost, high-performance 3D printing solutions with fast lead times, ideal for both prototype creation and series production of small series. Contact us today to learn more about our fast and trustworthy 3D printing service!

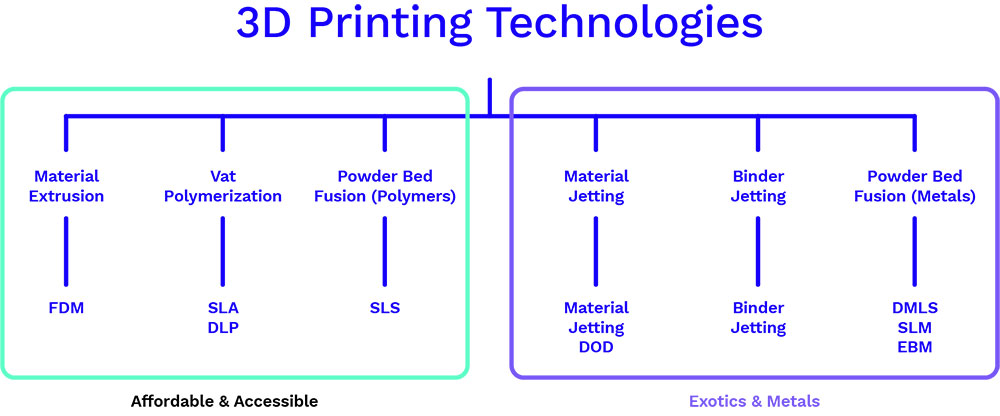

Explore Our 3D Printing Technologies

Holly offers different 3D printing technologies for end-use production and prototyping. We offer FDM, SLA, SLS, and SLM services that support high-accuracy printing of elastomer, metal, and plastic components with ±0.1-0.2mm tolerance. With post-processing treatments of different types, rapid prototyping, and small-series production, we offer superb aesthetics and mechanical performance. Holly aims to deliver efficient and trustworthy 3D printing services to help customers reach high-quality manufacturing in industries.

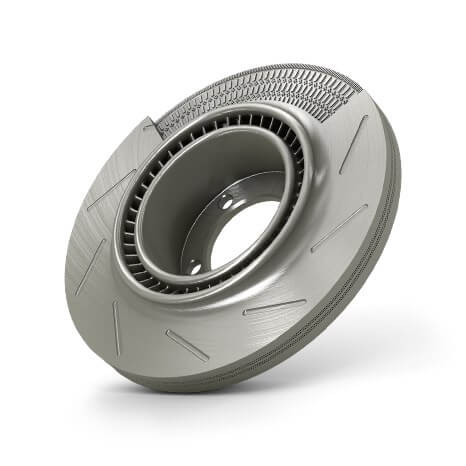

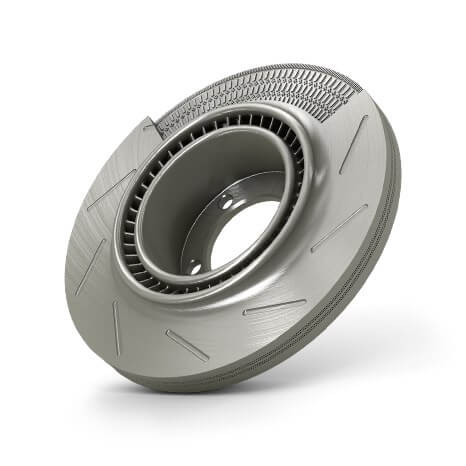

Metal 3D Printing

Direct Metal Laser Sintering (DMLS) uses a fibre laser system that draws atomized metal powder to the surface and welds the powder into fully dense metal parts.

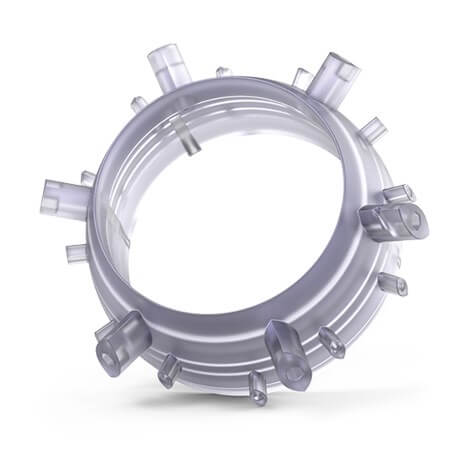

Stereolithography (SLA)

Stereolithography (SLA) uses an ultraviolet laser to form thousands of thin layers on the surface of a liquid thermoset resin until the final part is formed.

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) uses a CO2 laser to fuse nylon-based powders, layer by layer until the final thermoplastic part is built.

Multi Jet Fusion (MJF)

Multi Jet Fusion selectively fuses and refines fusing and refining agents onto a bed of nylon powder and subsequently employs a heater to sinter together the nylon powder to form a solid functional part.

3D Printing Capabilities

3D Printing Material Available

| PLA

PLA (Polylactic Acid) is a biodegradable thermoplastic commonly utilized primarily for low-cost 3D printing and rapid prototyping. Extremely highly rated for ease of printing, surface finish very high gloss, and environmental friendliness, PLA finds optimal use in concept models, educational applications, and household items. Although it offers greater dimensional stability with reduced warping, it has no heat resistance and is easier to damage compared to ABS. PLA can also be dyed and can be modified to be more flexible or rigid.

|

|

| ABS

ABS (Acrylonitrile Butadiene Styrene) is a hard, hard, and impact-resistant thermoplastic that is most commonly used in 3D printing for end-use parts and functional prototypes production. Because of its comprehensive use for its strength, heat resistance, and machinability, ABS finds extensive use in the automotive, consumer, and industrial markets. ABS possesses improved mechanical properties and is quite easily post-processed using acetone smoothing, paint, or sanding. ABS can further be blended in order to create improved resistance towards flame and UV stability and hence finds application in numerous applications.

|

|

| Nylon

Nylon (Polyamide, PA) is a tough Thermoplastic with superb abrasion resistance and strength. Nylon offers excellent mechanical properties of impact resistance and flexibility making it suitable for end-use parts and functional prototyping. It is used in automotive, industrial and consumer-grade applications where toughness and heat resistance are required. The self-lubricating aspects of Nylon are also perfect for gears, hinges, and moving parts. It can also be strengthened by adding fibers for more strength and stiffness.

|

|

| Resin

Resin is a high-resolution material used in SLA and DLP 3D printing. It’s great for prototypes that demand smooth surfaces and tiny details. It delivers superb dimensional precision, making it perfect for medical models, consumer goods, and complex engineering components. Common resins give a blend of strength and stiffness, whereas specialized resins – like flexible, durable, or high-temperature types – boost resilience and function. Resin prints can be improved through polishing, painting, or UV curing to enhance appearance and solidity.

|

|

| PC

PC (Polycarbonate), a tough thermoplastic, finds application in 3D printing in functional models and industrial use. With a high durability, heat resistance, and transparency, PC is applied to automotive, aerospace, and engineering components with strength needs in aggressive environments. It can be made to withstand high temperatures and post-processing to improve mechanical properties. Often applied in load-bearing parts, lighting, and protective gear, PC is appreciated for its high strength and transparency.

|

|

| Stainless Steel

Stainless steel is a corrosion-resistant metal that is highly effective in 3D printing to create high-performance, strong functional and industrial components. It is considered for its heat resistance, resistance to wear, and overall strength, which renders it perfect for aerospace, medical, automotive, and engineering industries. Stainless steel possesses sound mechanical strength and can be post-processed to further strengthen it to make it more functional as well as esthetically acceptable. It’s usually chosen for structural parts, tooling pieces, and high-stressed components where strength and durability is required.

|

|

| Aluminum

Aluminum, a heavy metal, of high strength and light weight is used routinely in 3D printing owing to its resistance to corrosion, thermal conduction, and hardness. This is applicable in aerospace, automotive, and industry where weight savings and high strength are the major requirements. Aluminum components manufactured by the 3D printing methods possess sufficient physical strength and can also be post-processed. Finishing operations like polishing, anodizing, or bead blasting improve surface attributes and performance. The economic affordability of the metal, coupled with its overall versatility, makes it a popular first choice for functional prototypes as well as end use.

|

|

| Titanium

Titanium is corrosion-resistant, lightweight, and high-strength metal that is widely 3D printed for corrosion resistance improvement, heat tolerance, and compatibility with living cells. It can be used well enough in aerospace manufacturing, medical equipment, and cutting-edge engineering applications involving strength-weight ratio. The mechanical titanium components 3D printed have higher mechanical properties, which are optimally favorable to structural materials and medical implants. Titanium components can be made post-processing compatible through polishing, blasting nozzle sanding, or anodization on the surface for better aspect and function.

|

|

| Copper

Copper is a metal conductor and is most commonly employed in 3D printing owing to the high electrical and thermal conductivity, corrosion resistance, and antibacterial activity. Copper is best utilized in electronic device-related applications, heat exchangers, and production where thermal conductivity and dissipation are required. Copper parts 3D printed with high reliability and precision are best utilized to specialized mechanical and electrical applications. Improved performance and looks can be achieved by applying post-processing techniques like polishing, bead blasting, and plating.

|

|

| TPU

TPU or Thermoplastic Polyurethane is a rubber-like plastic and is finding greater use in 3D printing wherever shock resistance, abrasion resistance, and elasticity are required. TPU feels rubber-like and is best used in automobile, shoe sole, medical implant, and seal gasket in production. TPU is abrasion-resistant and will flex and stretch but not deform. TPU printed objects may be post-processed with varying shore hardness levels as an attempt to achieve the appropriate level of flex.

|

|

| TPE

TPE or Thermoplastic Elastomer is a soft rubber-like material and is used mostly for 3D printing to be applied in products that require being soft, elastic, and strong. TPE, due to its high shock absorption and fatigue, is applied in wearable items, automobile components, grips, and seals. TPE prefers plastic and rubber with qualities like resilience and elasticity and excellent printability. TPE is available in varying shore hardness based on varying requirements of flexibility.

|

|

3D Printing Finishing Options

| Name | Description |

|---|---|

Sanding |

Smooth out surface roughness, improving aesthetics and texture. Used for resins, plastics, and metals. |

|

Polishing |

Removes layer lines and imperfections for a refined finish. Commonly used for FDM and SLA prints. |

Bead Blasting |

Creates a uniform matte finish by blasting fine particles onto the surface. Ideal for SLS and metal parts. |

Painting |

Adds color and protective coating to enhance appearance and durability. Suitable for plastics and metals. |

Electroplating |

Applies a thin metal layer to improve conductivity, wear resistance, and appearance. Used for plastics and metals. |

Ceramic Coating |

Enhances heat resistance and durability, commonly used for high-temperature applications. |

| Vapor Smoothing | Uses chemical vapors to melt outer layers, creating a glossy, smooth surface. Ideal for ABS and similar plastics. |

| Chemical Polishing | Enhances transparency and surface quality, mainly for SLA and SLS prints. |

| Impregnation | Seals porous parts with resin or other materials to improve strength and leak resistance. |

| Annealing | Reduces internal stress and enhances heat resistance and mechanical properties through controlled heating. |

| Texturing | Adds surface patterns for better grip or aesthetic appeal, commonly applied through post-processing. |

| Dyeing | It provides uniform coloration and is often used for SLS nylon parts. |

| UV Coating | Applies a protective UV-resistant layer to prevent discoloration and degradation from sunlight exposure. |

3D Printing Prototype Service FAQ

3D Printing Service – Ultimate FAQ Guide

In the following guide, you will know everything about 3D Printing Prototype.

3D printing is the name and terminology also known as rapid prototyping 3D printing. In ancient times, creating and 3D working was very expensive and slow, but with the latest and advanced techniques, you can do 3D printing with high quality and lower cost than what you need to develop a 3D printing prototype. The first and most important is that you must have access to 3D printing materials. The other two factors are saving time and money.

1. What is 3D printing?

3D printing or additive manufacturing is the process of creating three-dimensional objects from digital files. The creation of 3D printed objects is achieved through an additive process. During the adding process, an object is created through successive layers of materials until the object is created. Each of these layers can be thought of as a thinly sliced cross-section of the object. 3D printing is the opposite of subtractive manufacturing, where a milling machine is used to cut or hollow out a piece of metal or plastic. 3D printing can create complex shapes with less material than traditional manufacturing methods.

2. Why use a 3D printer for rapid prototyping?

In short, it’s fast and relatively cheap. Going from an idea to a 3D model, to a prototype in your hands is a matter of days, not weeks. Iterating is easier and less expensive, and you don’t need expensive molds or tools. Besides rapid prototyping, 3D printing is also used for rapid manufacturing. Rapid manufacturing is a new manufacturing method where businesses use 3D printers for short-run/low-volume custom manufacturing.

3D printing encompasses many forms of technology and materials, as 3D printing is being used in almost every industry you can think of. It’s important to think of it as a cluster of different industries with countless different applications. Here are some examples:

- Consumer goods (glasses, footwear, design, furniture)

- Industrial products (manufacturing tools, prototypes, functional end-use parts)

- Dental products

- Prosthetics

- Architectural scale models and drawings

- Reconstruction of fossils

- Imitation of ancient artefacts

- Evidence reconstruction in forensic pathology

- Movie props

3. Benefits of 3d printing prototype:

3D printing prototyping is very beneficial for the worker and organization but remembers that you can get help if you choose the right and good quality material. Moreover, you can get benefits if you choose the correct procedure because it saves them both time and money. The benefits of the 3D printing prototype are as follow:

1) You can create various iterations

Liberty in 3D printing is much more than that of other printing techniques. The beneficial aspects are beautiful and require design by using the digital 3D model and 3D modeling software. Moreover, this technology allows the world to create any project from scratch, and you can get more precise and quality visualization. This technique is helpful to make a variety of iterations. It means the prototype perfectly matched your desired product or fulfilled the requirements of your desired products.

2) Save Money

You can save the most significant portion of your income by using this technique because the cost or expense of photo printing is lower than injection molding and additive manufacturing.

Here the question comes to mind: what is the reason behind the lower cost? The biggest reason is that you can create the mould to create objects that are undoubtedly the most beneficial and significant advantage. Time and money are the two precious things for every company. Due to this reason, 3D printing is supportive and helps in creating objects for every organization.

3) Time saver

In addition to the most significant benefit of 3D printing, you can do several iterations as you want. Furthermore, the process of 3D printing prototypes is also speedy. Instead of creating the mould and waiting for the whole process of injection modelling, you can get direct access to the object. In conclusion, this technique and procedure are perfect for efficient or quick prototyping, which is very helpful in creating fast development of the project.

4) Run tests with functional prototypes:

We are very thankful for the availability of a variety of 3D printing materials and services available online. Due to the online shopping facility, access to the latest and advanced material is straightforward. Out of these many of the materials are adapted to production which is very helpful to use your prototyping process. So if you are required to do the test, these materials show you they have more advanced, impressive, and latest properties for manufacturing advanced and latest functional prototypes.

4. How does 3D printing work?

Producing a 3D part is a multi-step process. The first step is the making of an architectural design which is usually done with a CAD model or 3D Scan data. Then the file is converted into a readable format like OBJ or STL.

Already installed software in the printer adjusts the orientation, size, height and dimension, layers of the 3D model before printing. The print is formed using laser technology to cure the liquid resin into hard plastic or by fusion of small polymer particles at high temperatures to solidify.

Uncured liquid resin or excessive powder polymer particles are cleaned as the printing is done. It is clean by rinsing in isopropyl alcohol, compressed air, or media blaster depending on the printing technology.

1) Design

3D printers generate three-dimensional models of computer-aided design (CAD) software, and mathematical representations of any three-dimensional surface or 3D scan data develop. The design is then exported as an STL or OBJ file that print preparation software can interpret.

3D printers contain print settings software and divide the digital pattern into horizontal cross-sections of the component into layers. Adjustable printing parameters include guidance, layer height, material, support structures (if required). The program transmits instructions over a wireless or cable connection to the printer after the set-up is over.

2) 3D Print

Some 3D printers utilize a laser to cure liquid resin into solid plastic, while others employ high temperatures to fuse tiny particles of polymer powder to create components. Most 3D printers may be left unattended until the job is finished, and contemporary systems will automatically replace the material needed for the pieces from cartridges.

3) Post Process

The printed parts may need to be rinsed in isopropyl alcohol (IPA) to remove any uncured resin from their surface, post-cured to stabilize mechanical properties, manual work to remove support structures, or cleaning with compressed air or a media blaster to remove excess powder, depending on the technology and the material. With the help of accessories, some of these procedures may be automated.

3D printed pieces for specific purposes may be utilized immediately or after processing and the appropriate ends may be machined, primed, painted, or attached. In addition to traditional techniques of production, 3D printing sometimes acts as an intermediary stage such as positive for the investment of dental and dental gems and molds.

5. Processing of various 3D printing technologies

3D printing is a versatile technology and it is getting advanced day by day. Every day brings new specifications in this field. Different types of technologies are used for 3D printing; let’s go through some of these.

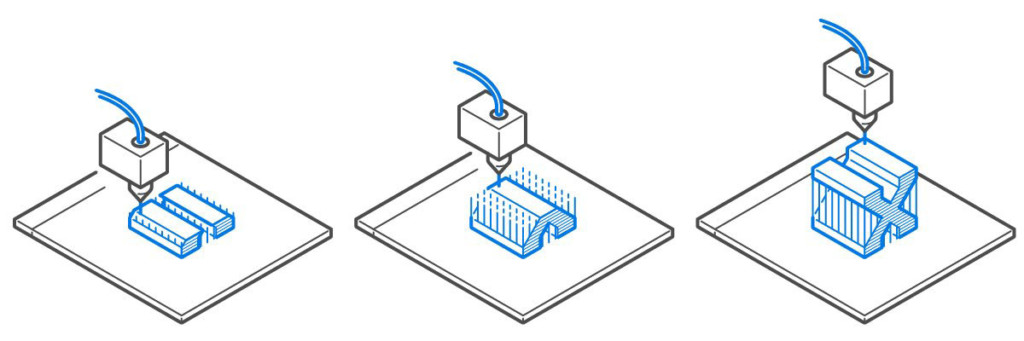

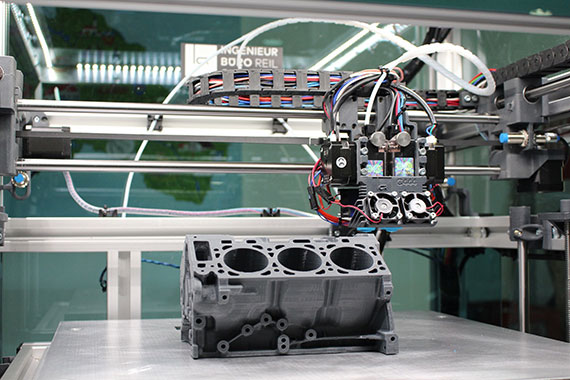

1) Fused Deposition Modeling (FDM)

FDM is a quick and low-cost printing technology with the lowest resolution and accuracy. But still, it is most widely used during the year 2021 with 71% of consumers utilizing it in houses. This technology is used to get simple prototypes for basic proof-of-concept models.

The FDM-based printers work on melting and extruding technology. The printers use thermoplastic filaments like polylactic acid. These filaments are heated and squeezed through the nozzle of the printer in liquid (melted) form. The melted liquid is cast gently layer by layer to form a sculpture.

2) Selective laser sintering (SLS)

Selective laser sintering (SLS) technology is popular for its high efficacy in making complex materials. It’s the second most widely used technology in the year 2021. It is an ideal choice for engineers to get functional prototypes at a low cost.

The technology works on sintering small parts of polymer powder into a solid structure. There is no need for any sort of anchoring material as the powder holds supporting properties. Nylon is the most commonly used thermoplastic in SLS technology. It bears excellent mechanical properties. Apart from this, it is easy to mold, lightweight and strong. Nylon is resistant to UV light, heat, dirt, water, and chemicals.

3) Stereolithography (SLA)

This technology is ideal for concept modelling, short-run production, functional and rapid prototyping, dental application, and in the jewellery industry. This is the most established and earliest form of 3D printing technology.

The SLA 3D works on a photopolymerization strategy. The technology in which a laser is used to cure the liquid into hardened plastic. The prototype produced as a result is highly accurate, watertight, and isotropic. Another benefit of this technology is a smooth finish with fine features. Stereolithography provides amazing mechanical, optical, and thermal properties.

6. Challenges in 3D Printing Process

Following the procedures mentioned above, one may believe that 3D printing is as simple as pressing the print button on a computer. A slew of stories in the news appears to guarantee the same thing. Unfortunately, this is no longer the case. The following are some of the areas where 3D printing varies from paper printing:

It is difficult to create useful 3D content. Though anyone can create a document for printing, creating 3D data requires the use of advanced design tools or scanning/digitizing devices. The capacity to utilize these goods entails training and money, which is out of reach for the typical customer.

Not everything in 3D is made identical. It does not mean that a 3D picture is printable because a 3D may be displayed on the computer screen. In addition to being particular, 3D printers need 3D data to comply with certain geometric limits.

So “middleware” software solutions are required, which receive input 3D data and turn it into 3D data, which can then be printed in 3D. The reuse of these systems calls for time and resources training and commitment.

7. Applications to 3d printing prototypes

The 3D printing or additive manufacturing technology is amazing for crafting the three-dimensional parts or the whole object using CAD (Computer-aided design). The printer squeezes material layers over layer till the formation of an object or prototype.

Producing a 3D part is a multi-step process. The first step is the making of an architectural design which is usually done with a CAD model or 3D Scan data. Then the file is converted into a readable format like OBJ or STL.

Already installed software in the printer adjusts the orientation, size, height and dimension, layers of the 3D model before printing. The print is formed using laser technology to cure the liquid resin into hard plastic or by fusion of small polymer particles at high temperatures to solidify.

Uncured liquid resin or excessive powder polymer particles are cleaned as the printing is done. It is clean by rinsing in isopropyl alcohol, compressed air, or media blaster depending on the printing technology.

It began in the 1980s but advancement in technologies and software made it accessible for most of the industries, like Engineering, manufacturing, dentistry, healthcare, education, entertainment, jewellery, audiology, and other industries are getting benefit from 3D printing since it speeds up innovation and helps businesses.

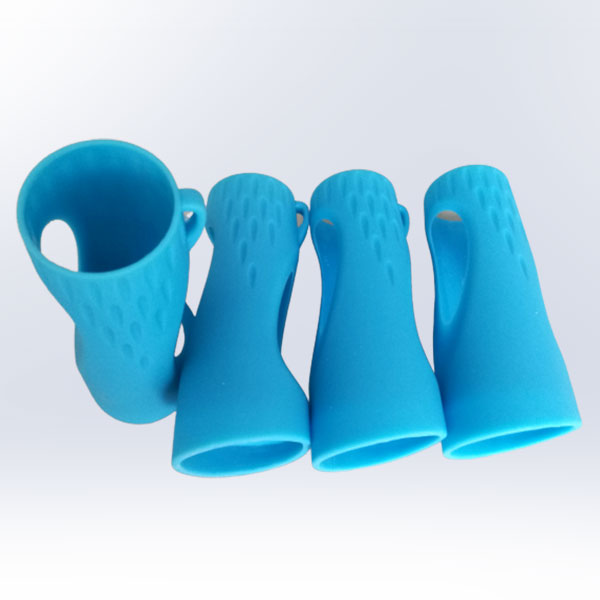

1) Audiology

The 3D printing technology is used in the formation of high-quality and custom audio products like earplugs, earbuds, behind-the-ear hearing aids, and hearing protection. The printing requirement is higher and more consistent. Most importantly it is recommended by a hearing specialist.

Audio products like earbuds and soft silicone earmolds are the latest trends in the market. Digital printing services are now affordable to custom fit ear devices for audiology, consumer audiology industries, and noise pollution.

This digital technology is helping to produce accurate and consistent prints for clinics by reducing the peeling force during printing. 3D printing is low cost and provides rapid production. Along with this, the technology made it possible to print any sort or size of a prototype; either it is tiny earbuds or large earmoulds.

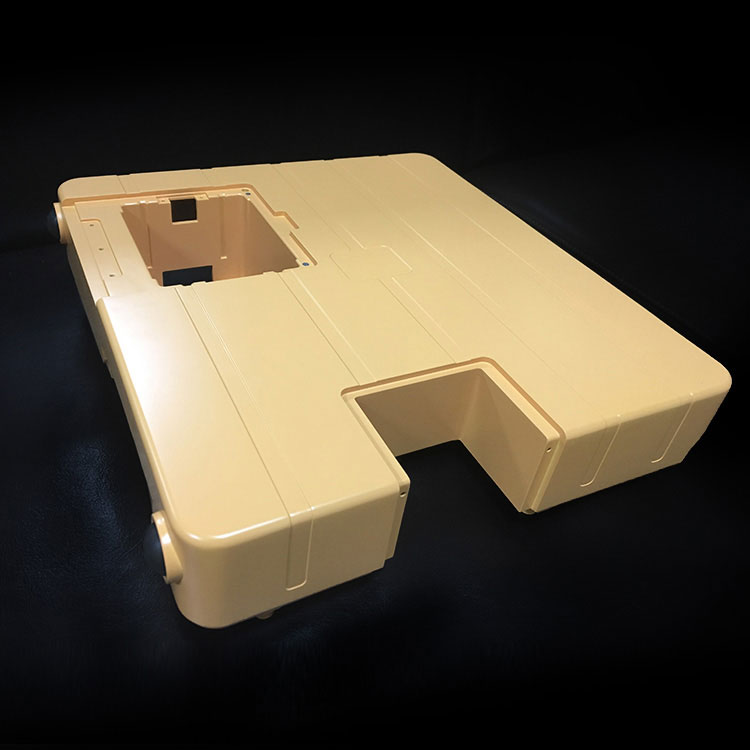

2) Manufacturing

Advance 3D printing technology delivers a broad spectrum in applications of prototypes. These prototypes are high precision and functional, bearing the characteristic to be the final product or part. 3D printing prototypes fasten the efficacy by providing tools that make the production process better and save money and time.

There is a list of prototype applications in the manufacturing industry. Digital printing catalyzes production at almost every level. Metal casting, molding, tooling, jig and fixtures, short-run production, and mass customization are some of the services of digital printing in this field.

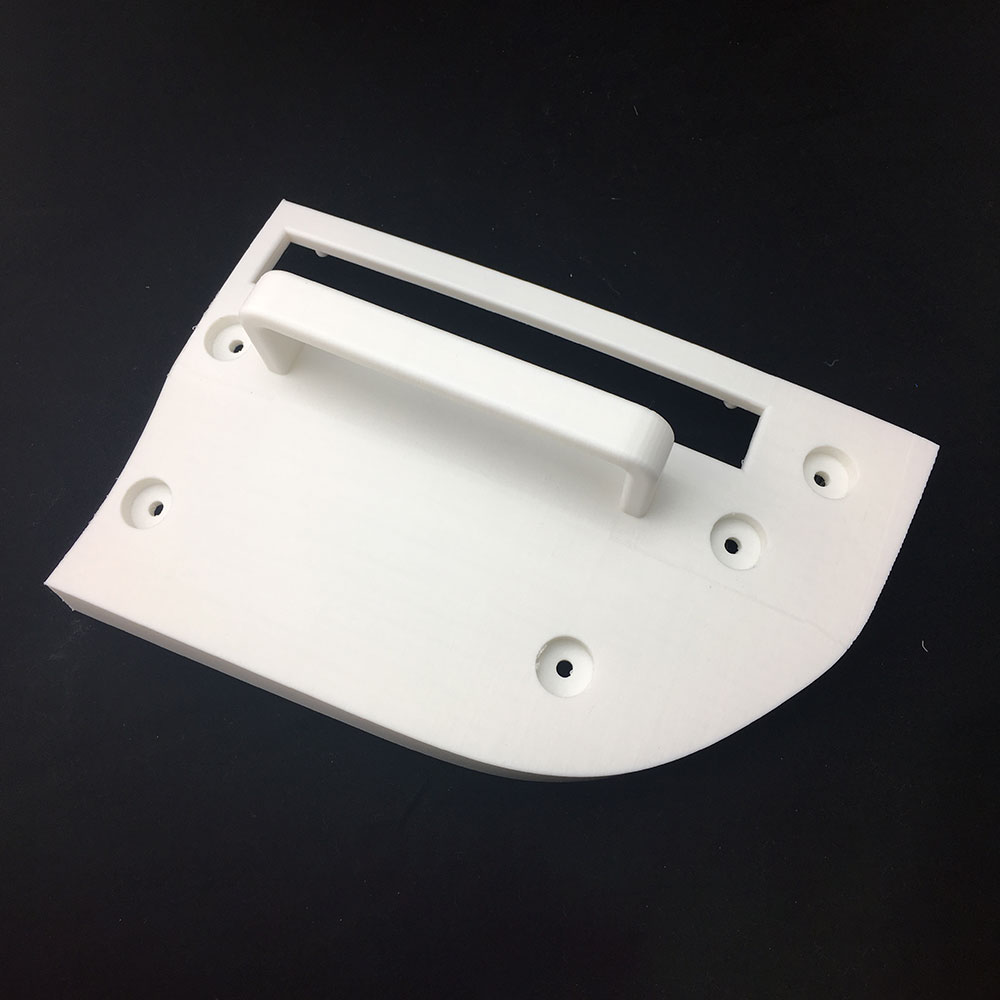

3) Engineering and Product Design

Rapid prototyping and design for manufacturing or design for assembling technologies are uplifting the industry of engineering.

DFM

Design for manufacturing (DFM) or design for assembly (DFA) technology provides ready to manufacture and assemble products by turning the specifications like geometrics, feature requirements, and mechanism, during the process.

This technology benefits the engineers in terms of speed, insignificant scrap rates, low part cost, and minimizing tools. Reliability is the key feature for the manufacturer using this tech.

Rapid Prototyping

The technique involved in creating a scale model of physical parts quickly is rapid prototyping. Rapid prototyping uses an additive fabrication technique that doesn’t require tooling. It provides instant models of the concept in no time, allowing the creators to visualize beyond imagination.

Sharing of ideas has become easy by showing them into realistic forms of conceptual models. Concept models aids in the identification of the flaws, and refinement of the models by clients, before production.

The multi-step process of production is now easy with this technology. The prototype can be evaluated at every stage to build a sharply define desired object.

4) Education

3D printers present learners the professional-level technology and creativity. The printing technology encourages advanced learning and helps students in research. STEAM curricula in design, arts, science and engineering now adopt digital printing services to make the learning experiences better.

Custom research setups, fab labs and mark spaces, Models for STEM curricula are the application of 3D printing services in the field of education.

5) Jewelry

The beautiful, elegant, and sharp-featured designs, in a short period with a variety of materials, are possible because of 3D printing services.

Fitting pieces of jewellery, creating master patterns for rubber molding, and lost wax casting are the digital applications in the jewellery industry. The application of this service in the field makes it convenient to print batches within a few hours.

The exceptional feature of 3D printing is it molds your choice into the desired prototype. What design you want, what size you think of, and what material you aspire, It’s all up to you. Nylon, paper, metal glass, ceramics, diamond, plethora, and all crude materials are choices for you.

Whether it’s a fine fabricated design or a micro-size product, you can get this with 3D printing technology. Which is sometimes not possible with traditional manufacturing? 3D printing also allows you to make new choices like ceramic jewellery.

6) Entertainment

Props, hyper-realistic sculptures, and character models are 3D printing prototypes. These applications are filmed in stop-motion movies, bespoke costumes, and video games. The digital printing service portrays high-definition models, which are also used for special effects in movies.

7) Dental Industry

Dentures, crown and bridges models, patterns for casting and pressing, clear aligner, Hawley retainer models, splints and occlusal guides, surgical guides are the applications of digital printing in the dental industry.