Custom OEM & ODM Automotive Plastic Injection Molding Solutions

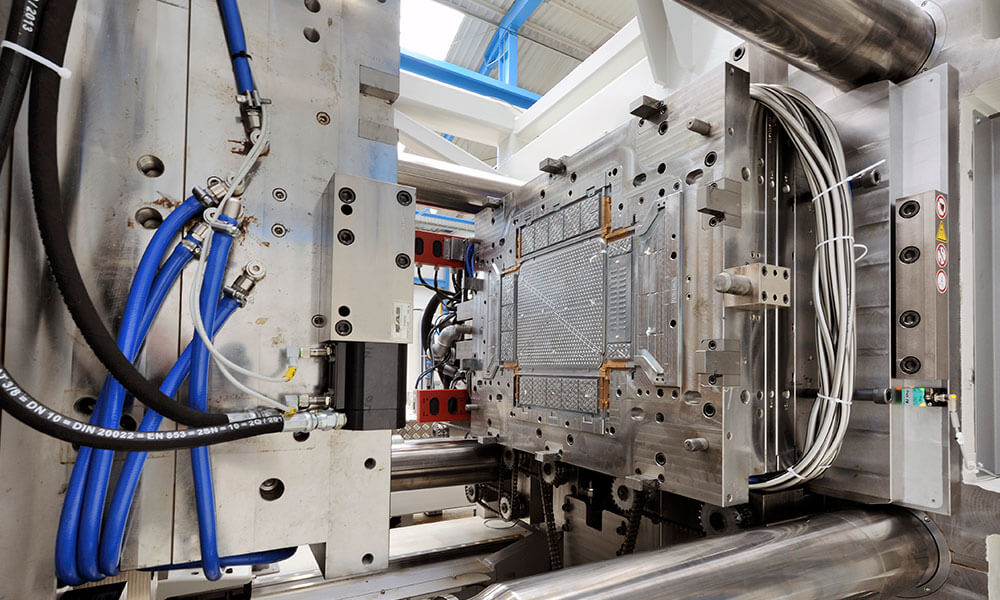

Holly Plastics has over 20 years of experience providing high-quality automotive plastic injection molding services to both primary and secondary car manufacturers. We offer a wide range of automotive plastic parts, each tailored to meet strict industry specifications and standards. Our extensive capabilities ensure that we can meet your specific design and performance requirements while providing cost-effective solutions that fit within your budget.

With hundreds of successful mold designs and production projects completed for some of the world’s largest automotive companies, Holly Plastics is a trusted partner in the automotive industry. We prioritize keeping your vehicle launch schedules on track, consistently delivering parts within the promised timeframes. Whether it’s mold design, prototyping, or mass production, we handle every stage with precision and efficiency.

At Holly, we specialize in both small-batch and large-volume production, offering fast turnaround times without compromising quality. Our state-of-the-art facilities, combined with skilled engineers and advanced injection molding technology, ensure superior durability and performance of each part. Contact us today to discuss your automotive plastic molding needs and discover why Holly is the ideal choice for your next project.

Explore Our Automotive Injection Molding Capacities:

Holly offers a variety of automotive injection molding molds of interior, exterior, and functional components, including single-cavity molds, multi-cavity molds, family molds, and custom-designed molds. We provide efficient and precise mold solutions tailored to meet the automotive industry’s requirements for high-quality, lightweight, and durable parts. With advanced mold design and molding technology, we ensure superior performance and durability of automotive components.

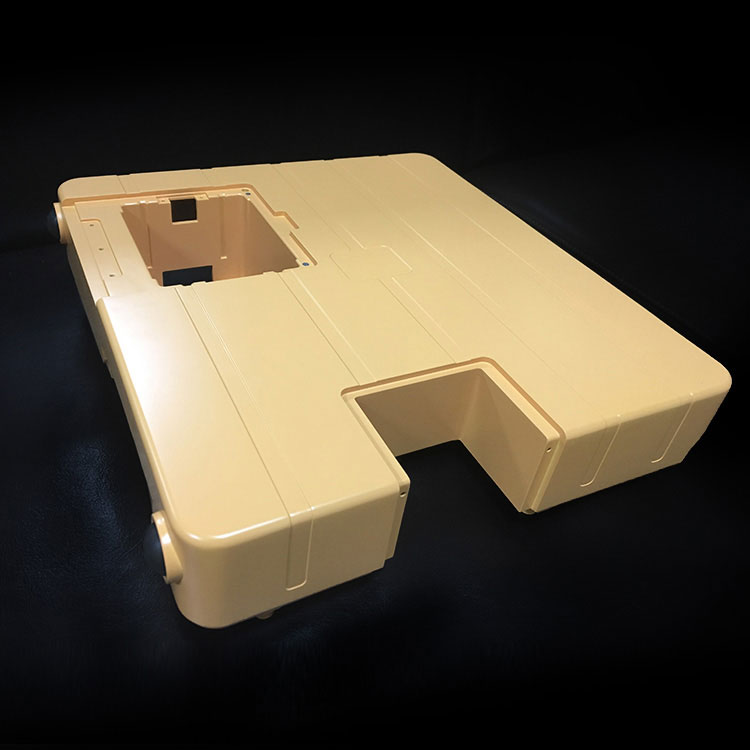

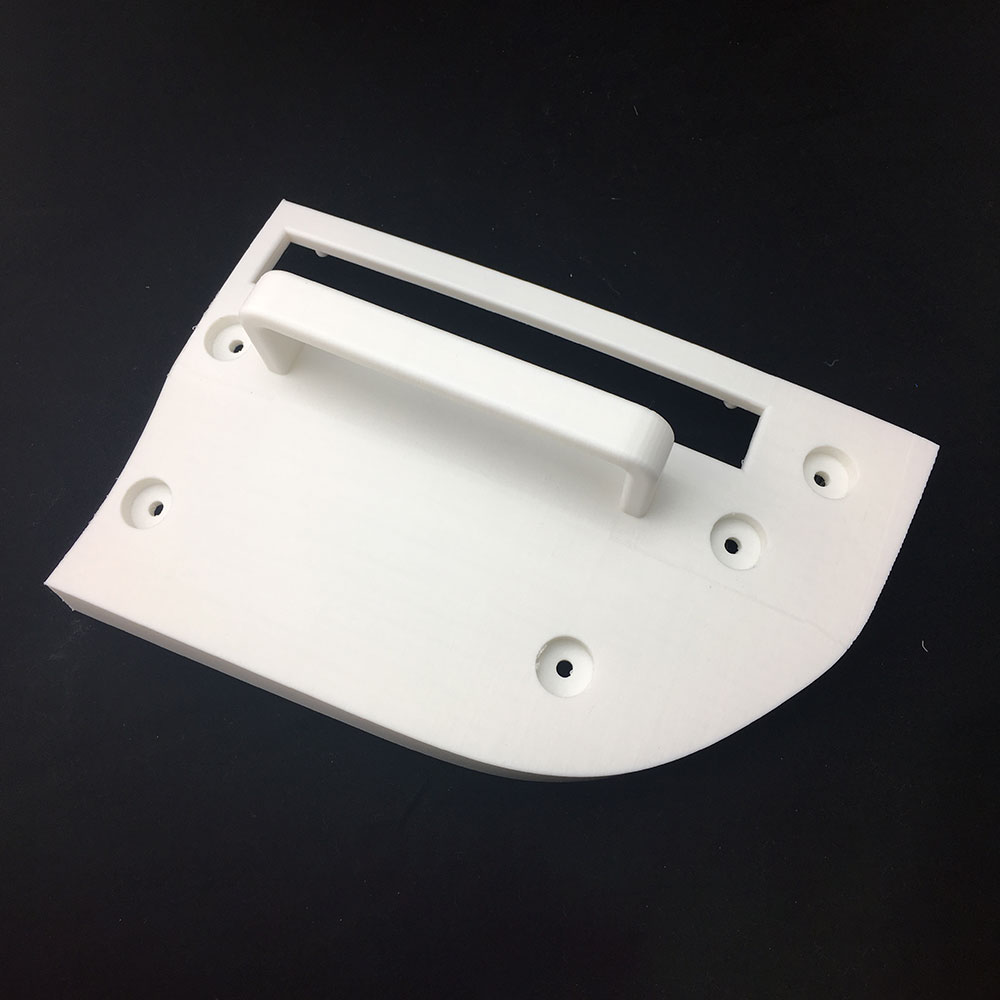

Featured Vehicle Components We Produced

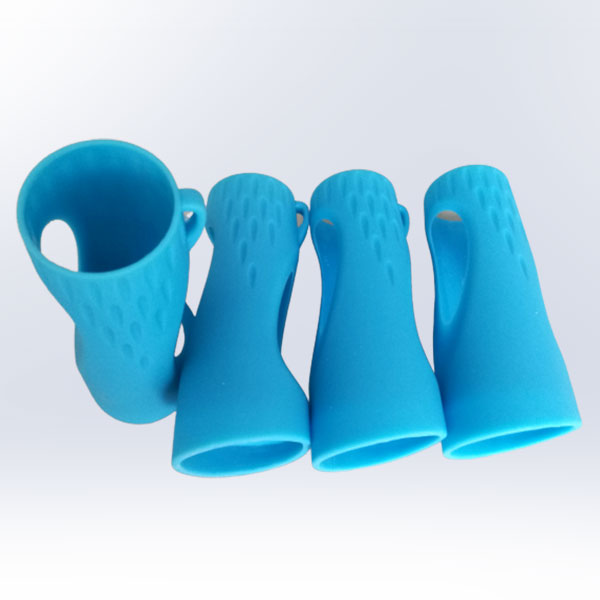

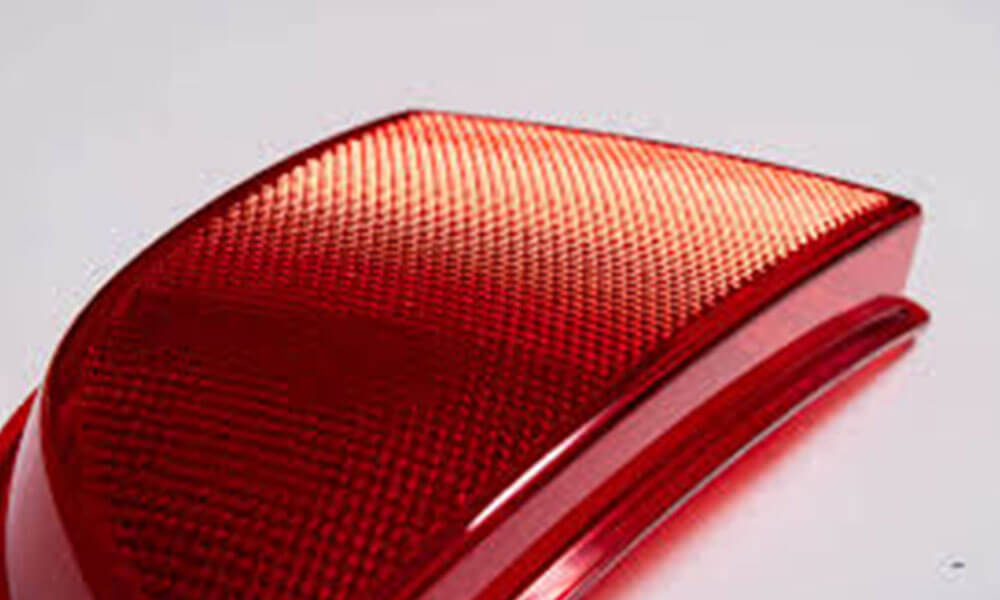

Holly specializes in high-precision automotive plastic injection molding, providing lightweight, durable, and cost-effective solutions for various automotive components. Our products include exterior parts such as bumpers, grilles, mirror housings, and light casings; interior components like dashboards, door panels, center consoles, and air vents; functional parts including clips, brackets, fasteners, and under-the-hood components; and electronic housings for sensors, control modules, and switch panels. With high-performance materials and advanced molding technology, we ensure exceptional precision, strength, and reliability in every automotive part.

Automotive Injection Molding Capabilities

Explore Our Latest Automotive Injection Molding Products

Discover the high-precision, durable parts we’ve recently produced for the automotive industry. With over 20 years of experience and a skilled engineering team, we deliver everything from prototypes to mass production. Click here to see our latest projects.

Automotive Plastic Injection Molding Materials Available

| ABS

ABS (Acrylonitrile-Butadiene-Styrene) is an excellent material for automotive injection molding due to its high impact resistance, rigidity, and ease of processing. It offers superior strength and durability, making it ideal for automotive applications that require precision and toughness. Common automotive parts made from ABS include dashboards, center consoles, mirror housings, and grille components. ABS’s ability to withstand tough conditions while maintaining structural integrity makes it a popular choice for both interior and exterior automotive parts.

|

|

| PP

PP (Polypropylene) is an ideal material for automotive injection molding due to its lightweight, chemical resistance, and high durability. It offers excellent impact strength and low moisture absorption, making it suitable for various automotive parts. PP is widely used in manufacturing automotive components such as bumpers, interior panels, battery cases, and air vents. Its versatility and ability to withstand harsh conditions make it a reliable choice for both exterior and interior automotive parts.

|

|

| PE

PE (Polyethylene) is an excellent material for automotive injection molding due to its flexibility, low friction, and chemical resistance. It offers high durability, low moisture absorption, and good impact resistance, making it ideal for automotive applications. PE is commonly used in manufacturing parts like fuel tanks, fluid reservoirs, and interior components such as door panels and trim. Its ability to resist wear and harsh chemicals makes it suitable for automotive environments.

|

|

| PS

PS (Polystyrene) is well-suited for automotive injection molding due to its ease of processing, low cost, and good surface finish. It provides high clarity and rigidity, making it ideal for parts that require smooth surfaces. PS is commonly used in automotive applications such as interior lighting components, trim panels, and air vents. Its ability to be molded into intricate shapes and lightweight nature makes it a reliable choice for decorative and functional parts.

|

|

| PC

PC (Polycarbonate) is ideal for automotive injection molding due to its high strength, impact resistance, and optical clarity. It offers excellent durability and heat resistance, making it suitable for demanding automotive environments. PC is commonly used in automotive parts such as headlamp lenses, instrument clusters, and sunroofs. Its ability to maintain transparency and withstand high temperatures makes it a preferred choice for exterior and safety-related components.

|

|

| Nylon

Nylon (Polyamide) is ideal for automotive injection molding due to its high strength, wear resistance, and ability to withstand high temperatures. It offers excellent durability, low friction, and chemical resistance, making it suitable for demanding automotive applications. Nylon is commonly used for parts like engine components, timing gears, fuel lines, and clips. Its ability to perform under stress and extreme conditions makes it a reliable choice for automotive functional and structural components.

|

|

| PU

PU (Polyurethane) is highly suitable for automotive injection molding due to its excellent flexibility, durability, and resistance to wear, abrasion, and chemicals. It offers superior elasticity and impact resistance, making it ideal for parts that experience frequent stress. PU is commonly used in automotive applications such as seats, bumpers, interior panels, and gaskets. Its ability to absorb shocks and maintain structural integrity under harsh conditions makes it a reliable choice for both functional and aesthetic automotive components.

|

|

| PET

PET (Polyethylene Terephthalate) is ideal for automotive injection molding due to its excellent chemical resistance, dimensional stability, and high strength. It offers superior durability and heat resistance, making it suitable for parts exposed to high temperatures. PET is commonly used in automotive applications such as fuel tanks, air intake manifolds, and electrical enclosures. Its strength and stability under harsh conditions make it a reliable material for both functional and structural automotive components.

|

|

| PTFE

PTFE (Polytetrafluoroethylene) is ideal for automotive injection molding due to its exceptional high-temperature resistance, low friction, and chemical stability. It performs well in extreme conditions, providing durability and reliability. PTFE is commonly used in automotive applications such as seals, gaskets, and bearings. Its ability to resist wear, heat, and chemical exposure makes it a preferred choice for components that require long-lasting performance in engines, transmission systems, and other critical automotive parts.

|

|

| HDPE

HDPE (High-Density Polyethylene) is ideal for automotive injection molding due to its high strength-to-density ratio, impact resistance, and excellent chemical stability. It is lightweight, durable, and can withstand harsh conditions. HDPE is commonly used in automotive applications such as fuel tanks, underbody shields, and fluid reservoirs. Its resistance to chemicals and moisture makes it an excellent choice for components exposed to high-stress and challenging environments.

|

|

Automotive Plastic Injection Molding Finishing Options

| Name | Description | Can be Applied with |

|---|---|---|

Glossy Finish |

A smooth, reflective surface that enhances visual appeal and provides a high-end look. | Interior parts like dashboards, center consoles |

|

Matte Finish |

A non-glossy, smooth surface that resists fingerprints and scratches, providing a soft feel. | Door panels, seat components, trim pieces |

Textured Finish |

A surface with a tactile texture that adds grip and reduces glare. | Interior panels, seat backs, door handles |

Chrome Finish |

A shiny, metallic surface offering a luxury, high-end appearance often used for decoration. | Grilles, door handles, side mirrors |

Wood Grain Finish |

A finish that mimics natural wood, giving an elegant and high-class look to interior parts. | Dashboard trims, door panels, console covers |

Painted Finish |

A finish achieved through painting offers a wide range of color options and visual appeal. | Exterior parts, interior trim, body panels |

| Glossy Aluminum Finish | A shiny metallic finish that provides a modern and sleek look, often used for accents. | Control buttons, air vents, trim pieces |

| Soft Touch Finish | A soft, velvety feel that enhances comfort, often used on parts that are frequently touched. | Seats, steering wheels, armrests |

Automotive Plastic Injection Molding FAQ

Automotive Plastic Injection Molding – Definitive Guide

In the following guide, you will know everything about automotive plastic injection molding.

Mold is an important foundation of industrial production and is often referred to as the “mother of industry”. With the rapid development of the automotive industry, automotive molds have become the most important part of the mold industry, and the scale of the industry continues to expand.

Under the promotion of the national automobile lightweight policy, the development of automobile lightweight is an inevitable trend, which will effectively promote the development of automobile injection molds.

1. What Are Auto Parts?

Auto parts are products that make up the entire car and service car. mainly includes:

1) Auto parts

Door handle bracket, rear cover, vent cover, bulb cover, filter housing, front energy absorber, housing intake manifold, upper intake housing, switch board, etc.

2) Inside and outside of auto parts

Door handles, side mirrors, liner covers, window sill covers, door covers, beauty covers, front door panel substrates, speaker grilles, window decorations, pillars, door panels, front carpet holders, inner hatch covers, etc.

3) Auto parts grille and FASCIAS

Front grille chrome, front upper fascia, front upper fascia, front upper and lower fascia, front lower grille closed

4) Auto parts lighting, instrument panel

5) Chrome bezel mask, bezel mask base, bezel mask, headlight bezel, headlight housing, headlight bezel, centre console bezel, instrument panel, taillight reflector bezel, optics Mirror bezel, light pipe, steering column guard

2. What are the Applications of Auto Parts?

In the automotive industry, auto parts are used to manufacture a variety of models, including. Cars, coupes, hatchbacks, station wagons, vans, SUVs, pickups, convertibles, sports cars, etc.

The usage of auto parts is staggering. Plastic is commonly found in car interiors. Automotive products are trying to completely change the way plastics are used in cars. Plastic is lighter, cheaper, and more durable, which makes it a trend in the automotive industry.

3. What are the material properties of auto parts?

1) The modulus and impact strength are both balanced (both hard and tough; excellent dimensional stability, that is, the material should have good creep resistance under long-term load).

2) Good temperature resistance, to ensure that the material will not be deformed under light and high-temperature conditions.

3) It has special surface properties, such as matt, high hardness, scratch resistance, easy painting, electroplating, etc.

4) Good weather resistance, to ensure long-term use does not change colour, does not age and crack (including thermal oxygen ageing and light ageing).

5) Good chemical resistance, can resist the erosion of oil and daily chemicals.

6) It is easy to mold, has sufficient fluidity for injection-grade materials, ensures the molding of complex parts, and improves productivity.

7) Economy requires materials with high-cost performance.

4. What materials are used for auto parts?

1) Nylon material (PA)

Nylon is mainly used for automobile engines and engine peripheral parts. The main varieties are GFPA6, GFPA66, enhanced flame retardant PA6 and other products. In automotive engines, peripheral parts primarily comprise heating and vibrating parts, so the materials most commonly used are glass and plastic fiber reinforced nylon. This is because nylon has better comprehensive properties. After modifying nylon with glass fiber, its main properties have been greatly improved, such as strength, product accuracy, and dimensional stability.

In addition, after modifying the variety of nylon and glass fiber, the main properties of nylon have been greatly improved, such as strength, product accuracy, and dimensional stability. Another reason nylon is an ideal material for engine peripheral components is its variety, ease of recycling, cheap price, and other characteristics. In addition, the application in automobile engine parts: engine hood, engine decoration cover, cylinder head and other parts generally use modified nylon as the material choice. Compared with metal, such as cylinder head, the quality is reduced by 50% and the cost is reduced. 30%.

2) Polyester material (PBT)

In the field of automobile manufacturing, PBT is widely used in the production of automobile parts, such as bumpers, carburetor parts, fenders, spoilers, spark plug terminal blocks, fuel supply system parts, instrument panels, automobile ignition, accelerator pedals, Clutch pedal, etc.;

3) Organic glass (POM)

The automobile industry is the largest potential market for POM. POM has the advantages of lightness, hardness, wear resistance, creep resistance, and chemical resistance. POM is very suitable for manufacturing automobile pumps, carburetor parts, fuel lines, power valves, universal joint bearings, motor gears, cranks, handles, instrument panels, window regulators, electric switches, seat belt buckles, etc., especially Wear-resistant parts such as sliders modified with POM. The advantage of POM is that these parts wear less metal, reduce the consumption of lubricants, and increase the service life of the parts.

4) Polycarbonate material (PC)

PC modified for use in automobile interior and exterior trim as well as instrument panel periphery, antifreeze plates, door hinges and door casings, because it is heat resistant and impact resistant, rigid and fluid in processing handle, downflow plate, bracket, steering column guard Covers, decorative panels, air-conditioning system components, etc. Lamp fittings and other auto parts.

5. What are the main aspects of evaluating the performance of auto parts?

First, the quality of appearance, including completeness, colour, and gloss. The second is the accuracy between size and relative position, that is, size accuracy and position accuracy. Third, the mechanical, chemical, and electrical properties corresponding to the application, that is, functionality. Therefore, if the problem occurs in any of the above three areas, it may lead to product defects.

6. What are the common defects of auto parts?

Short shots, flashes, bubbles, shrinkage, weld marks, black spots, bubbles, streaks, warping, delamination, peeling, etc.

7. What are the key technologies for automotive mold manufacturing?

1) Visual and intelligent design.

Most automobile molds are more complicated. The use of 3 d mold design can realize visual design, so that not only can three-dimensional and intuitive reproduction of unprocessed molds, specifically, the real integrated CAD/CAM, and 3 d design can also solve some of the difficulties. The problem to be solved is in the 2D design, Such as interference check, simulation assembly, etc.

2) Simulation technology.

Make a simulation of the automotive injection molding process using the MOLDFLOW analysis software MOLDFLOW, find problems ahead of time, optimize the mold design, and ensure the success of mold manufacturing and operation.

3) Standardization of production methods.

Including the standardization of enterprise management, the standardization of automobile mold design, and the standardization of mold manufacturing.

4) High-speed precision cutting technology (high-speed machining).

High-speed precision machining technology is used in automobile mold manufacturing, which has the advantages of high cutting efficiency, high machining accuracy, and good surface quality, so that computer operation gradually replaces manual labor, and ultimately achieves the purpose of improving mold quality. Shorten mold making time and reduce mold cost.

5) High-precision testing equipment and online testing technology.

The precision of automobile molds is very high. We need to make full use of high-precision testing equipment and online testing technology to control the dimensional accuracy of the mold on site to ensure that the parts produced can meet the design requirements.

6) Injection molding using hot runners and sequentially.

Making full use of hot runner and sequential injection technology can improve the productivity and product quality of automobile molds, while greatly saving raw materials.

7) Adopt new steel and mold surface treatment technology.

Mainly use steels that are easy to process, good in polishing, and whose surface requirements can make up for the deficiencies of die steel.

8. What is the commonly used steel for automobile molds?

738, 738H, NAK80, 2083, S136, etc., die steel depends on die life and product quantity. We can choose the steel type according to your requirements.

9. What elements can be provided in the quotation of car dashboard mold?

The following is an example of Honda car dashboard mold:

- The material is PP+PE.

- The main cavity and core steel are 1.2738H HRC 34-38.

- The slide rail steel is 1.2344-HRC 48-52.

- The injection system is a process from hot runner to cold runner.

- The hot runner system includes an appropriate number of hot valve nozzles and sequential injection controllers.

- The grid mold runs on a 2800 T injection molding machine.

- The production cycle of this mold is about 16 to 18 weeks.

10. What are the factors that affect the price of automotive molds?

1) The size and shape of automobile products can be simple or complex. As a result, the mold’s structure is determined, and mold costs are directly linked to that.

2) The appearance of auto parts, normal requirements, and processing costs that are completely different from high requirements.

3) The number of mold cavities, one cavity or multiple cavities, will affect the structure and size of the mold.

4) The annual quantity of parts or mold life, which determines what kind of steel is used, which directly affects the price of the mold.

11. What are the advantages and disadvantages of injection molding for auto parts?

Injection molding of auto parts has several advantages, including:

- Cost-effective, especially for mass production

- Process repeatability and product consistency

- Operator and user safety

- Lightweight alternatives to metal parts

However, this process also has some disadvantages. For example, it may require high upfront tool costs, and any redesign may require additional time and money.

12. How long is the delivery time of auto molds?

The general definition of “delivery time” is the total time from when an order is received to when the product is completed and delivered to the ordering company. However, in the mold industry, the definition of lead time is different. For example, for automobile molds, the delivery time is calculated from the approval of the mold drawing to the customer and the first payment until the first mold test, while a typical mold takes 5-6 weeks from the beginning to T1, it can be as much as Cavity molds require 7-10 weeks or more complex molds.

The longer lead time may be due to the type of injection system, such as hot runner, high surface and high tolerance size requirements. In addition, the procurement of designated components, such as hot runner systems and imported components, also requires additional time.

13. Why is mold quality important to auto parts?

With the development of economy, the quality of auto parts occupies an important position in the auto industry, and the quality of molds will directly determine the quality of auto parts. When selecting a mold manufacturer, automotive manufacturers and auto parts manufacturers pay great attention to the ability of the mold manufacturer as well as the price and quality of the mold quality of the automobile mold. The Holly team has more than 20 years of experience in manufacturing car molds for many well-known car brands, so if you have any car projects, please feel free to contact us.

14. Why is it necessary to make prototype molds for auto parts?

Because the prototype mold is a very effective way to develop new products in the early stage, and better meet the specifications at a lower cost. Samples can also be obtained in the fastest way so that the functional performance of parts can be tested before investing a large amount of cost to manufacture a series of molds. At the same time, this is also a good way to seize market opportunities and meet customer needs. The Holly team will carefully evaluate your role and provide professional advice for your role. Regarding this problem, you can have no worries.

15. How to control the quality of auto parts during the injection molding process?

1) Molding cycle

This is known as the molding cycle. A molding cycle is the length of time required for injection molding to be completed. The molding cycle directly affects labor productivity and equipment utilization. Therefore, in the production process, quality assurance should be taken as the prerequisite to minimize the relevant time in the molding cycle. The injection time, as well as the cooling time, are crucial to the quality of the product throughout the entire molding cycle.

2) Pressure control

A crucial aspect of injection molding is that of plasticizing plastics and infusing them because the two pressures directly affect plasticization and quality.

3) Temperature control

The temperature that needs to be controlled during the injection molding process is the barrel temperature, Nozzle temperature, mold temperature. In the first two temperatures, the plastic is mainly affected by plasticization, while in the third, it is primarily affected by flow and cooling.

16. How to maintain the surface of the car mold?

Attention should be paid to the surface maintenance of automobile molds. The surface quality of products is affected directly by this factor. The focus is on rust prevention. Therefore, it is very important to choose a suitable, high-quality and professional rust prevention oil.

When the mold has finished production, different methods should be used to carefully remove the remaining. According to different injection molding, injection molding and copper rods, copper wires, and professional mold cleaning can be used to eliminate the remaining injection molds and other deposits, and then air dry.

It is strictly forbidden to remove the residue with iron wire, steel bar or other hard objects to avoid scratching the surface. Use a grinder to remove rust spots on the injection molding, then use rust-prevention oil to clean the mold and store it in a dry, cool, and clean environment dust-free place.

17. How does Holly improve the accuracy of auto parts?

The accuracy of auto parts is a combination of injection molding, plastic raw material characteristics, injection molding machine performance, and injection molding machine technology. The following is Holly’s solution:

1) Holly’s professional technical team provides excellent design solutions for your automobile mold structure, which can achieve the best accuracy requirements.

2) Materials with good toughness and stable performance are recommended for auto parts based on their functions.

3) During the injection molding process, professional operators accurately Materials with good toughness and stable performance are recommended for auto parts based on their functions. The injection mold, and there will be no problems such as excessive pressure and burrs.

4) To effectively ensure product quality, experienced operators regulate injection speed.

5) The trained operator controls the processing temperature to make the raw material evenly colored and finish smoothly.

6) Holly is equipped with high-precision injection molding machines, which can better meet your high-precision requirements.

18. How can I get a quote for a car mold?

1) If you have drawings, you can send the drawings and required information to us:

- 2d (dwg, pdf, jpg)

- 3d (stp, step, igs, x_t)

- material type.

- Surface treatment requirements.

- Annual volume of parts or die life.

- Mold cavity.

2) If you don’t have drawings, you can send samples to us: We can make a drawing based on your sample (1-2 days) and send it to you for review.

3) No picture and no sample. You can give us the size details. We can make drawings for you based on the information.

19. Can prototype molds of auto parts save me costs?

Under normal circumstances, most people think that making a prototype mold is just an extra step, which will slow down the overall development and production speed, which means more costs. In fact, if there is no prototype mold, the production mold will make more adjustments and modifications. This led to the delay of the entire project.

Generally speaking, a prototype mold has a cavity and cheap steel. This allows welding and cutting, and even changing the position of the gate. If necessary, you can modify it. Even so, the overall cost is about 20% of the total cost of producing the mold. If all the modifications are made directly on the production mold, then any modification will have a great cost loss and time delay, and it will also reduce the performance of the mold and shorten the life. Therefore, prototype molds are indeed an important way to save costs.

20. How many ways are there to prototype car parts?

Prototyping is a necessary stage to make plastic prototypes easy and affordable. There is a range of manufacturing techniques capable of producing plastic prototypes. Holly has several methods to help you release it, such as 3D printing, CNC machining, and injection molding to create plastic prototypes. These technologies have their own advantages. The advantages of 3D printing are suitable for products with complex structures and small volumes.

CNC machining is suitable for large, simple, and relatively inexpensive products, while injection molding is suitable for large-volume products. You can choose the right way according to the size and quantity of your auto parts. If you are not sure about this, the Holly engineering team will help you choose the best solution.

21. Why choose Holly as my automotive project partner?

Holly Engineering Department is an excellent technical team. Engineers with more than 10 years of experience can use the latest engineering software to directly bring your CAD model into the mold design. Such as AutoCAD, UG, Pro/E, Solid works, etc.

All mold designs are in line with your automotive mold standards and specifications. All of these can ensure the quality of your automobile injection mold, please don’t hesitate to contact any of our support.

22. How does Holly guarantee the quality of my car mold?

Holly has 20+ experience in automobile mold production, directly or indirectly producing automobile molds for global customers. Our strength is the world’s advanced high-precision equipment, with an accuracy tolerance of 0.005.

In addition, our professional engineering team can carefully evaluate your auto parts and provide optimized solutions to design your molds. After your approval, start manufacturing with standards and strict management.

So as to ensure the high precision of each step. Thanks to our precise equipment and professional team, we can ensure the high quality of your car molds. Our customers are well-known brands, such as Honda, Toyota, Peugeot, Ford, BMW, Volkswagen, Audi, Land Rover, etc. Holly will be your reliable partner for automotive mold manufacturing.

[lwptoc skipHeadingText=”*Automotive Plastic Injection Molding|*Holly Automotive Injection Molding Service|*Holly’s expertise in the automotive industry includes the manufacturing of:|*Featured Vehicle Components We Produce:|*Automotive Plastic Injection Molding FAQ|*Automotive Plastic Injection Molding – Definitive Guide|*Custom OEM & ODM Automotive Plastic Injection Molding Solutions|*Explore Our Automotive Injection Molding *Capacities:|*Grille Mould|*Console Board Mold|*Door Trim Mould|*Fender Mould|*Bumper Mould|*Gear Shift Cover Mould|*Featured Vehicle Components We Produced|*Automotive Injection Molding Capabilities|*European Quality, Asian Price, Excellent Engineer Team|*Automotive Plastic Injection Molding Materials Available|*Automotive Plastic Injection Molding Materials Available|*ABS|*PP|*PE|*PS|*PC|*Nylon|*PU|*PET|*PTFE|*HDPE|*ABS|*PP|*PE|*PS|*PC|*Nylon|*PU|*PET|*PTFE|*HDPE|*Automotive Plastic Injection Molding Finishing Options|*Explore Our Latest Automotive Injection Molding Products”]