Plastic Part Design for Injection Molding

The company provides one-stop new product development services including custom product design, industrial design, rapid prototyping, engineering design and contract manufacturing. The company has a strong engineering team and advanced equipment. We design, engineer, prototype and manufacture products in-house. No matter how perfect our product development and design solutions are, we always need to improve and optimize part manufacturing.

Our product design and manufacturing teams consider ease of production, reliable quality and cost-effectiveness throughout the product design and development process. Our talented team works closely with clients to ensure projects are of high quality, on time and on a minimum budget.

Featured Mold Design Process

Product Idea

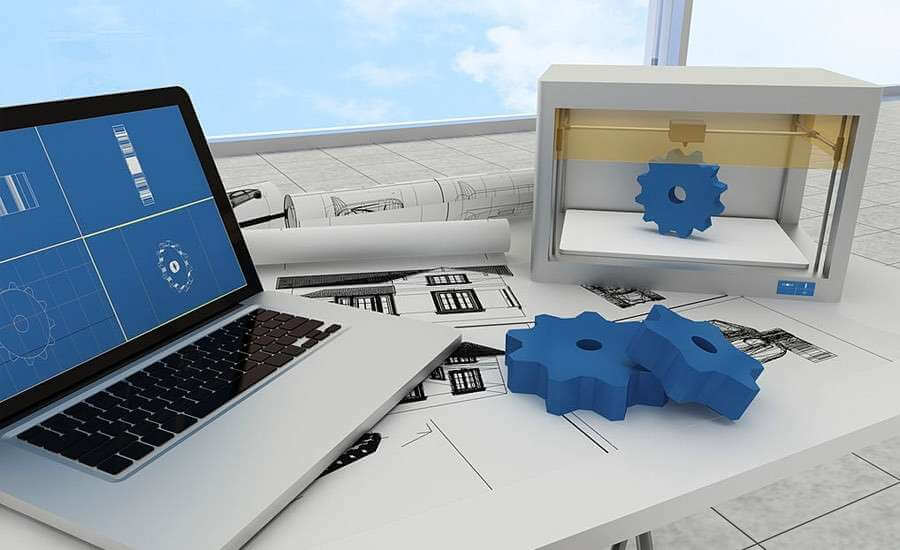

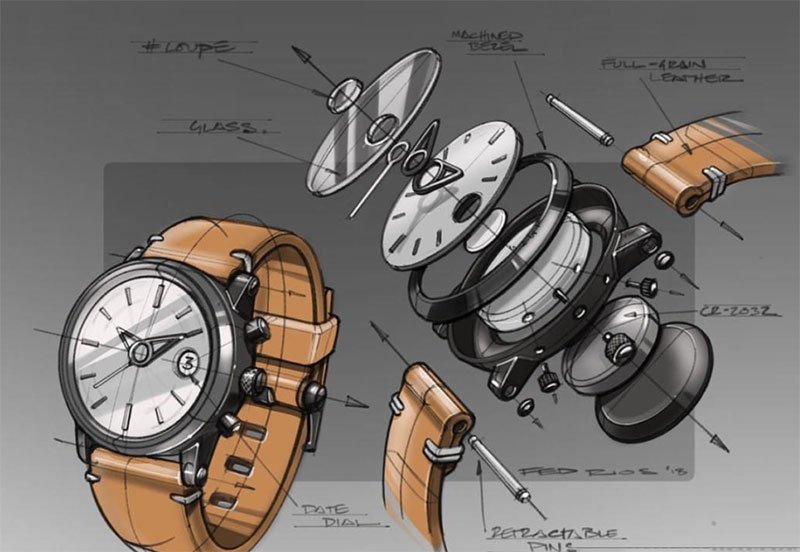

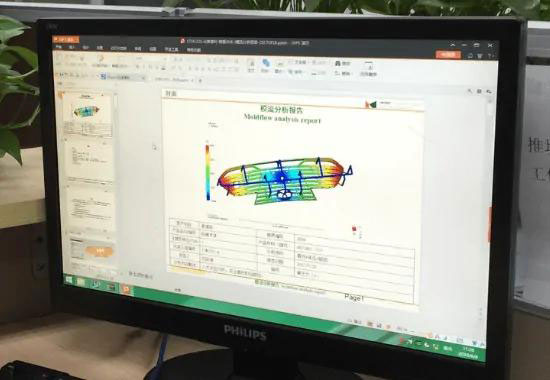

Based on your product definition creative concept from the design stage, our product designers will create, sketch and develop your product’s visual flow. The design process includes initial Cad design, mechanical engineering, electrical engineering, 3D Cad development, finite element analysis and stress testing.

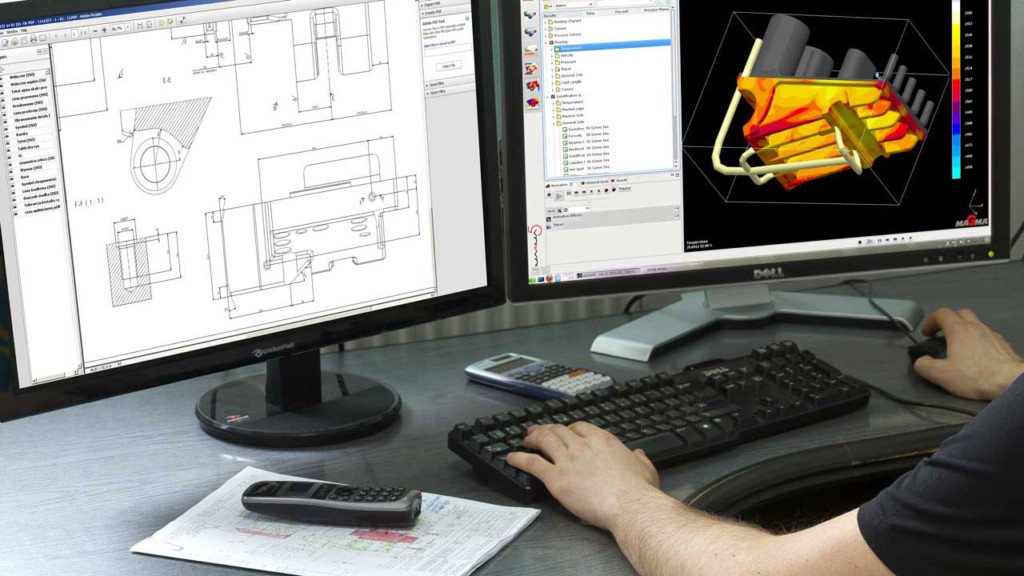

Product Design

Following your product definitions originating from a creative concept in the design phase, our product designers will create, sketch, and develop the visual flow of your product. The design process includes Initial Cad Design, Mechanical Engineering, Electronics Engineering, 3D Cad Development, FEA Analysis & Stress Testing.

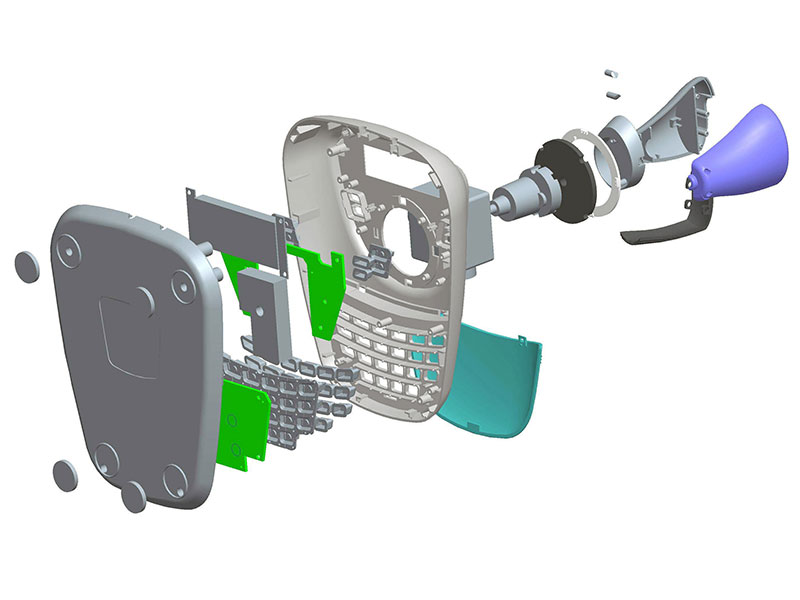

Prototyping and Testing

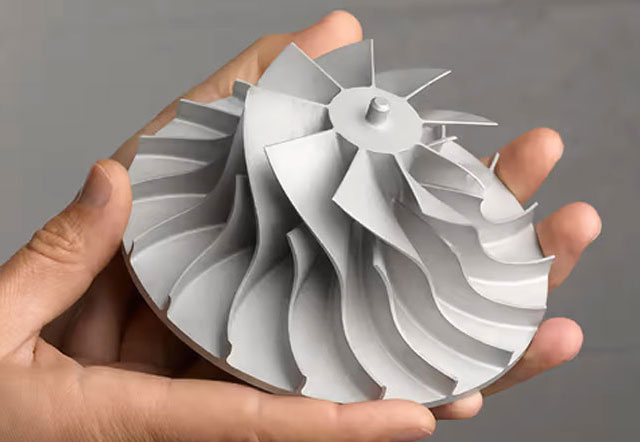

Holly’s in-house rapid prototyping workshop is equipped with 3D printing, SLA, CNC machines and prototyping, which allows our customers to quickly turn around prototype parts. So conceptual modeling can turn these ideas into reality in as little as 3 days. It gives us the flexibility to create and test so your product can get to market better and faster. We make prototypes throughout the product development process to double-check and evaluate their fit, form and function.

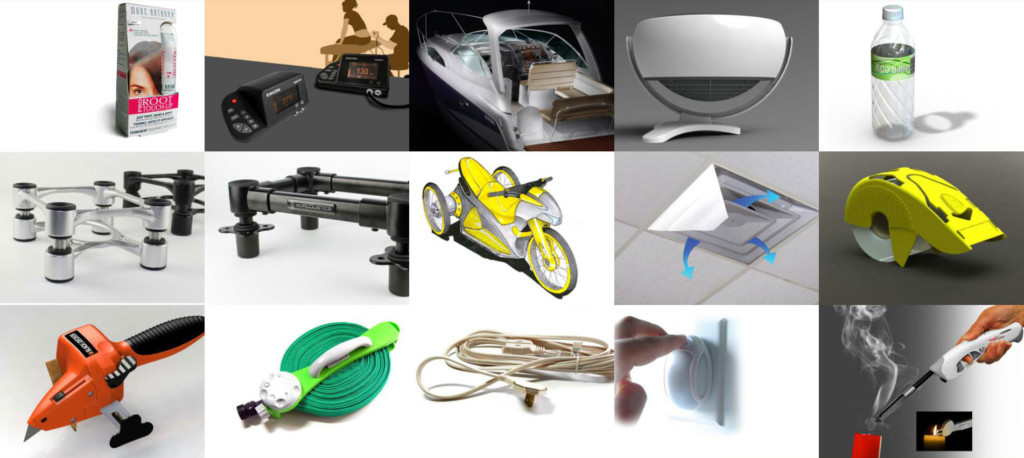

Manufacturing to Market

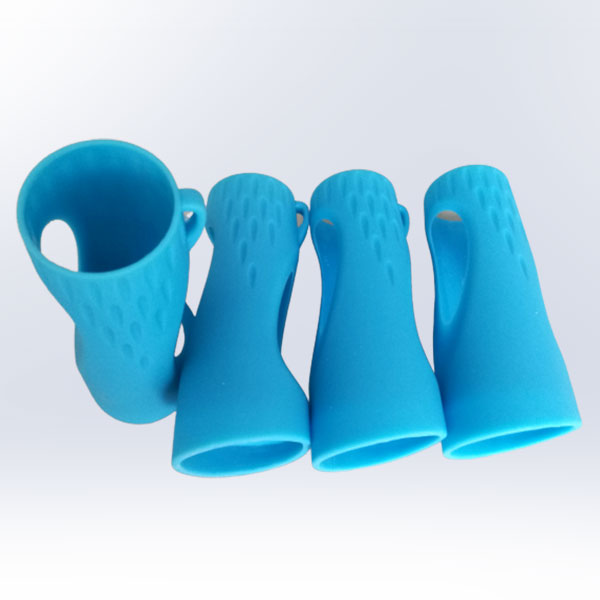

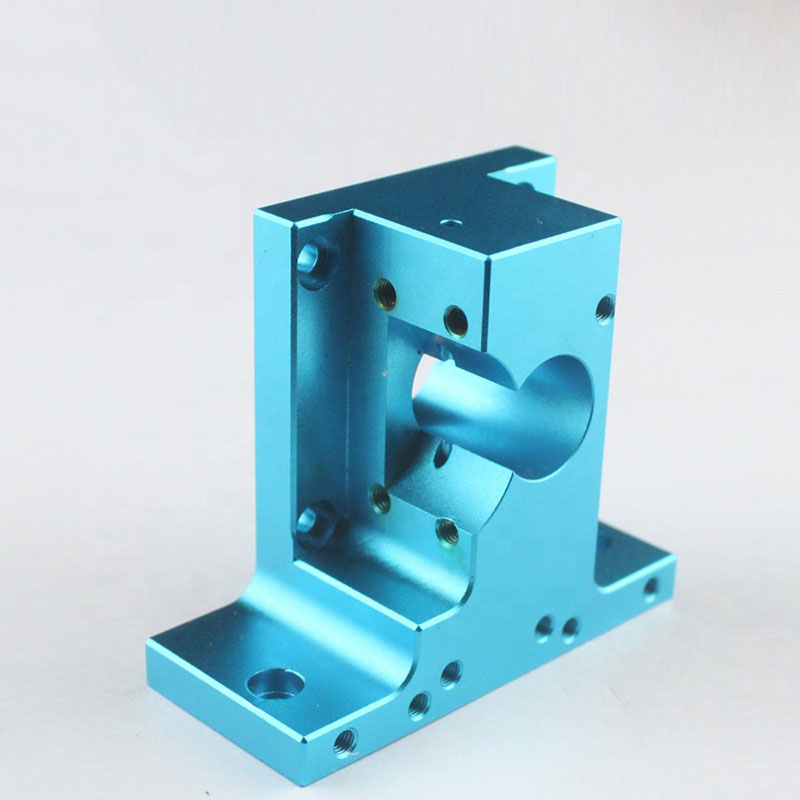

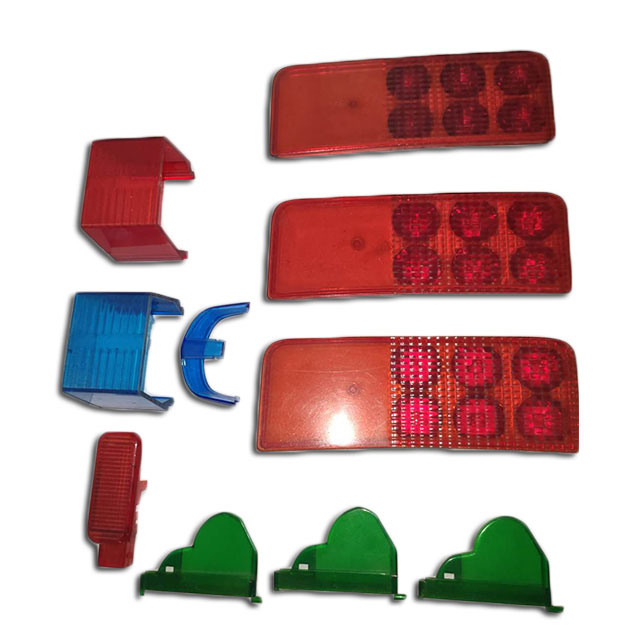

After the customer confirms the product design, Holly will provide processing services such as mold manufacturing, CNC machining, injection molding, and die casting. At the same time, secondary processing is carried out internally, including screen printing, pad printing, painting, electroplating, anodizing, assembly, etc. We do everything we can to ensure a good first impression when a product is released.

Our Recent Projects

Injection Mold Design Service – Ultimate FAQ Guide

In the following guide, you will know everything about Injection Mold Design Service.

Product Design for Injection Molding – Ultimate FAQ Guide

As a product design specialist for all kinds of molds and products, Holly can turn your ideas into reality in as little as 48 hours. Here, we share this guide with you. Trust that you can get most of your enquiries and our company from it. If you find out what we can do to support you, please feel free to contact us. We are available 24/7/365.

Q1. What is product design?

Product design as a noun refers to a series of technical work from creating a new product design task to designing a product sample. Its work content is to formulate product design tasks and implement the project requirements in the design tasks (including product performance, structure, specifications, models, materials, internal and external quality, life, reliability, conditions of use, technical and economic indicators, etc.).

As a verb, product design is the creation of new products for a company to sell to customers. Through the process of generating new products, a wide range of coefficients are generated and ideas are efficiently proposed and developed.

Q2. What are the principles of product design?

1. Intimacy: Intimacy means putting all related things together. When you put related things together, you can get a more comprehensive, functional product, and even have unexpected results.

2. Alignment: In a design, all elements should be placed in a specific way. There are certain connections between each element, between individual elements, and between elements as a whole. The result is a harmonious and beautiful experience.

3. Contrast: The core purpose of the comparison is to form a primary and secondary relationship, that is, the information passed first, the information passed later, etc.

4. Repeat: Repetition, as a very important element in the design, makes the whole design look more consistent and forms a unified design expression.

Q3. What is the importance of product design?

In the product design stage, people need to comprehensively determine the following issues: the entire product strategy, appearance, structure, function, so as to determine the layout of the entire production system. Therefore, product design is of great significance.

If the design of the product lacks manufacturability, the equipment will need to be adjusted and replaced. To make matters worse, people will have to spend a lot of money on materials and labour. On the contrary, good product design not only reflects functional advantages, but also facilitates manufacturing, reduces production costs, and thus improves the overall competitiveness of products. Many companies that are good at winning in market competition pay great attention to the details of product design and design products with low cost and distinctive features.

Q4. What are the requirements for product design?

There are 4 requirements in total.

1. Social development needs

This is beneficial to buy time to plan, select and concentrate on the introduction of the world’s advanced technologies and products. It is conducive to filling the technical gaps as soon as possible, cultivating talents, and obtaining economic benefits.

2. Economic requirements

3. Requirements.

4. Manufacturing process requirements

The most basic requirement of product design is that the product structure should conform to the principle of craftsmanship. That is to say, under certain production scale conditions, people can produce parts that meet the quality requirements in an economical way. This helps to design product structures that minimize labour in product manufacturing, reduce product weight, reduce material consumption, and shorten production cycle and manufacturing costs.

Q5. What are the economic benefits of product design?

One of the main purposes of new product design is to meet the ever-changing demands of the market and obtain better economic benefits. Good design can solve all kinds of problems that customers care about. For example, what is the function of the product? How does it feel? Is it easy to assemble? Can it be reused? At the same time, good design can save energy and raw materials, improve labour productivity, and reduce costs. Therefore, three issues need to be considered when designing the product structure.

- We have to consider the performance and quality of the product.

- Raw materials and manufacturing costs must be considered.

- It is also important to consider whether the product can be mass-produced.

Q6. What are the usage requirements for product design?

For a product to be recognized by society and obtain economic benefits, it must proceed from the needs of the market and users and fully meet the requirements for use. It is the minimum requirement for product design. The use needs mainly include the following items:

Safe to use: when we design products, we must take effective measures to prevent and protect against various unsafe factors during use. At the same time, the ergonomics of the product should also be considered in the design.

Reliability of use: Reliability refers to the probability that a product will work properly for a specified period of time and under intended conditions of use. Reliability is about safety. Products with low reliability will bring inconvenience to users, even cause danger to use, and damage the reputation of enterprises.

Easy to use: This is especially important for civilian products (such as household appliances, etc.).

Q7. What is the portfolio design of product design?

Combination design, also known as modular design, is to unify the functions of parts and design them into interchangeable modular parts with different uses or different performances to better meet the needs of users. Modular components are now widely used in various product designs. Furthermore, they have grown from producing the same type of product to produce a wide variety of products. Designing a series of modular components is at the heart of compositional design.

Therefore, it is necessary to start with functional units. That is, how many components should be included in several modular assemblies, how many modular assemblies are required for each combined design, and so on.

Q8. What is computer-aided design for product design?

Computer-aided design is the use of computers to complete product and process design. The main function is drawing and design calculation. Design calculations are based on engineering and scientific laws, such as the mechanical design with computers and calculations with optimization techniques to optimize specific performance parameters or goals for the internal structure of products.

Computer graphics are done by people through graphics processing systems. In this system, people only need to input the shape, size and position of the required graphics, and the computer can automatically complete the graphic design. In addition, commonly used computer-aided design software are Alias, Rhino, Autocad, Pro/E, CATIA, Solidworks, UG NX, CAXA, etc.

Q9. What is object-oriented product design?

In the product design phase, manufacturability and assembly designs are the negotiation and communication between designers and manufacturing engineers. This kind of teamwork is very important. Here are some reasons for your reference.

First, it avoids a wide variety of products, which can result from the traditional “I design, you do” design process.

Second, it helps prevent potential assembly problems and results in additional costs (such as manufacturing costs, material costs, labor costs, machine costs, etc.).

Last but not least, it avoids delays in the delivery of parts.

Q10. What are the basic principles of product design?

There are many basic principles of product design.

And enumerates some common principles: demand principle, information principle, innovation principle, system principle, optimization principle, inheritance principle, benefit principle, time principle, simplification principle, quantitative principle, etc.

Q11. What are the requirements principles for product design?

The functional requirements of a product are derived from requirements. Product is the most basic starting point for all designs including part design and must meet objective requirements. Failure to consider objective requirements will result in wasted parts and excess inventory. Objective needs are based on time and place, so it is variable. It is the basis for designing upgraded products. There are two types of objective needs: explicit and implicit.

The development of accurate requirements can lead to continuous product improvement, upgrades, updates and replacements; The development of hidden needs can lead to inventions and new products.

Q12. What are the information principles and innovation principles of product design?

1. Information principles

The information in the design process mainly includes market information, scientific and technological information, technical testing information, and processing technology information. Designers need to have an accurate and reliable grasp of various information related to product design. Using this information, product planning, conceptual design, and detailed design can be properly guided to continuously improve the part design.

2. Innovation principles

The bold innovation of designers helps to break through the constraints of various traditional concepts and conventions and create various mechanical products with unique principles and novel structures.

Q13. What are the service areas of product design?

Product design is a comprehensive product of knowledge from various disciplines such as art, culture, history, engineering, materials, and economics. Product design mainly coordinates the relationship between products and people and realizes the requirements of product ergonomics and humanistic aesthetics, including ergonomics, appearance design, etc.

Responsible for the selection of technology types, coordinating the relationship between different technical units such as product interior, product and natural environment, product technology and production process. In short, the service field of product design is quite extensive.

Q14. What is the first phase of product design?

Concept development and product planning are the first stages of product design. During the concept development and product planning stages, information on market opportunities, competitiveness, technical feasibility and production needs are integrated to define the framework for the new product.

This includes the conceptual design of the new product, target market, expected performance levels, investment needs and financial implications. Companies can also use small-scale experiments to validate concepts and opinions before deciding whether to develop a new product. Experimentation can include sample making and soliciting opinions from potential customers.

Q15. What is the second stage of product design?

The detailed design phase is the second phase of product design. During the detailed design phase, once the plan is approved, the new product project will move to the detailed design phase. The basic activities of this phase are the design and construction of product prototypes and the development of tools and equipment for commercial production. Detailed product engineering revolves around the “design-build-test” cycle.

The required products and processes must be conceptually defined and embodied in a product prototype (either in a computer or in the form of a physical entity using hypermedia technology), and then the product is tested in simulated use. If the initial shape does not reflect the expected performance characteristics, engineers should seek design improvements to make up for the difference and repeat the “design-build-test” cycle. The end of the product detailed engineering phase signifies that the final product design meets the specified technical requirements and is signed off for approval.

Q16. What is the third stage of product design?

The small-scale production stage is the third stage of product design. During the small-scale production phase, individual components processed and tested on production equipment are assembled and tested in the factory as a system.

In small-scale production, a certain number of products should be produced and the ability of the new or improved production process to be tested for commercial production should be tested. During this phase of the product development process, the entire system (design, detailed design, tooling equipment, parts, assembly sequence, production supervision, operators and technicians) is brought together.

Q17. What is the last phrase of product design?

The final stage of product design is incremental production. It is also a stage for small-scale production. In incremental production, production starts at a relatively low output level; When an organization has greater confidence in its (and its suppliers’) ability to sustain production and to sell those products in the marketplace, production of parts begins to increase accordingly.

Q18. What are the perceptual factors of product design?

The design of perceptual tools should make full use of the achievements of modern ergonomics and aesthetics to scientifically increase the perceptual factors in product design.

1. Reasonably design the relationship between people and tools to reflect the sensitivity of the product. For example, the handle is designed so that the pressure-insensitive palm and the area between the thumb and index finger can withstand the impact of force to avoid numbness and tingling in the fingers.

2. Select the correct modeling materials to increase the sensory components of the product. Here are two tips for choosing materials that come into direct contact with people. First, we do not only have to carefully evaluate the strength and wear resistance of the material. Second, we also evaluate the distance between the selected material and the emotional relationship between people.

3. Study the aesthetic methods of modern people and express the sensibility of products. The beauty of a product can reflect the inner beauty produced by a reasonable human-machine relationship and the outer beauty produced by the appearance of the product during use. The external beauty of products and people’s aesthetics are changing. The rich connotation of “beauty in shape” also contains changing aesthetic factors. In work, the laws of beauty such as proportion, scale, contrast and balance are coordinated with the visual image of the product and transformed into aesthetic factors. Therefore, understanding the changes in the aesthetics of modern people is helpful to grasp the perceptual factors in the product.

4. Through the research on the relationship between life phenomena and things, explore the reasons and performance methods of product sensitivity. The beauty of an object is usually reflected in whether the shape of the object is full of vitality, and the vitality of the shape of the object is actually a form of leakage of the essence of the object.

Q19. What is the industry background of product design?

From the perspective of industrial form, the industrial design service industry can be reflected in three categories: internal design service departments, industrial design consulting companies, and individual studios of industrial designers. The first two are mature products that the design industry has developed to a certain extent. In China, most small and medium design firms are still in the studio stage.

Large-scale low-end competition has emerged in some industries, which also limits the design industry to a certain extent. On the other hand, in Finland, industrial design has a very broad field, from forestry machinery to technological products. The average proportion of Finnish companies using the industrial design is 41%, compared to 80% in traditional industries. All Finnish export companies have their own designs.

According to the “Finnish Human Resource Market Status” issued by the Finnish Chamber of Commerce and Industry, the population of Finland engaged in industrial design is about 45,000, while the total population of Finland is about 5.435 million, which means that designers in Finland account for 0.828% of the total population.

Compared with developed countries, the overall level of product design in my country is relatively backward. Product design companies do not pay enough attention to this, and the public’s understanding of product design is also biased. As a “world factory”, China’s independent design and brand capabilities are still weak, and there is a lack of corresponding capital investment and industrial support policies.

Q20. Which software can be used for product design?

Product design software can be divided into two types: one is two-dimensional software (also known as plane software), and the other is three-dimensional software. Graphics software includes Adobe Photoshop (PS), Coreldraw (CDR), Illustrator (AI), InDesign (ID), AutoCAD, etc. 3D software includes UG, Rhino, Keyshot, Cinema4D, 3Dmax, Pro/Engineer (Pro-e), Solidworks, etc. When we do product design, we can choose the software we are good at.

[lwptoc skipHeadingLevel=”h1,h3,h4″ skipHeadingText=”Injection Mold Design Service – Ultimate FAQ Guide|Plastic Part Design for Injection Molding|Featured Mold Design Process|Product Design for Injection Molding – Ultimate FAQ Guide”]