Custom Electronics Plastic Injection Molding Solutions

Holly is a leading provider of high-precision Electronics Plastic Injection Molding solutions, catering to a wide range of industries, including electronics, automotive, medical, and consumer products. Our advanced injection molding technology enables us to produce complex, high-precision components with fast turnaround times, whether you need rapid prototypes or large-volume production.

We work with a broad selection of high-performance materials to meet the specific requirements of the electronics industry, such as heat resistance, electrical insulation, and durability. From small batch runs to large-scale production, our facilities are equipped to deliver consistent, high-quality results, ensuring each part meets stringent global standards like CE and RoHS certifications.

At Holly, we prioritize cost-effective solutions without compromising quality. Our experienced team and ISO-certified processes ensure reliability and performance in every project. Whether you need custom designs or standard components, we offer tailored solutions that help bring your electronic products to life. Contact us today for your injection molding needs!

Explore Our Electronics Plastic Injection Molding Capacities:

Holly offers a variety of molds for Electronics Plastic Injection Molding, including single-cavity, multi-cavity, family molds, and custom designs tailored to electronic components. Our advanced molding technology ensures precision and high-quality production for parts like connectors, housings, and enclosures. With a focus on material efficiency and durability, we deliver lightweight, reliable products that meet the demanding performance standards of the electronics industry.

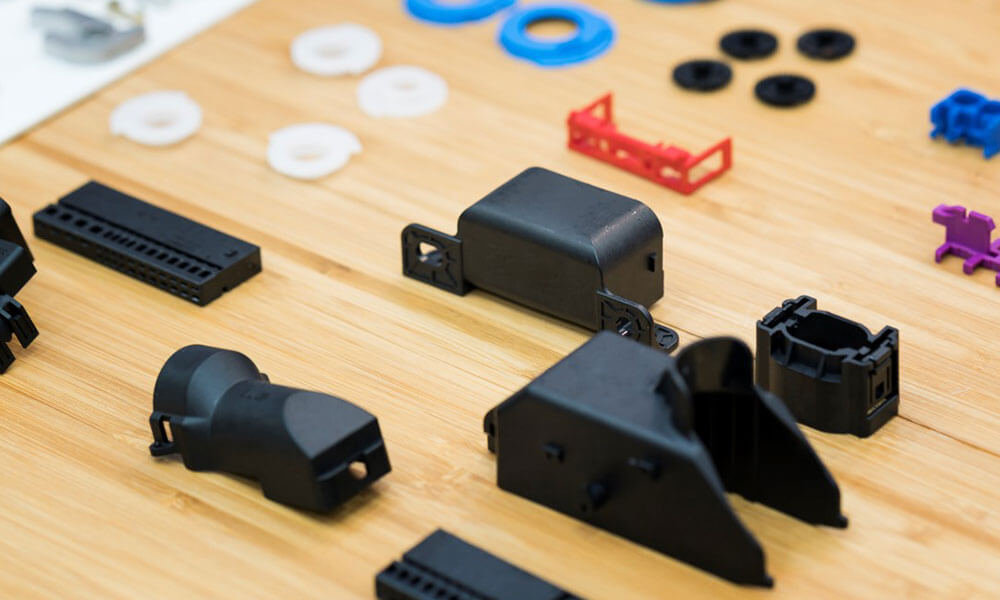

Featured Electronics Components We Produced

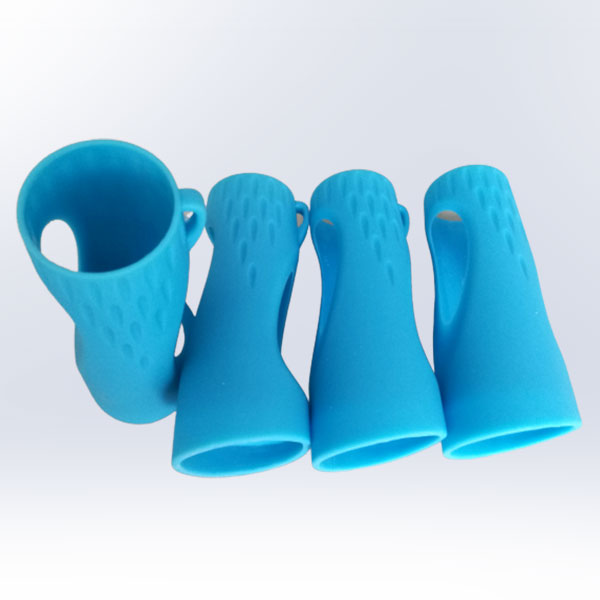

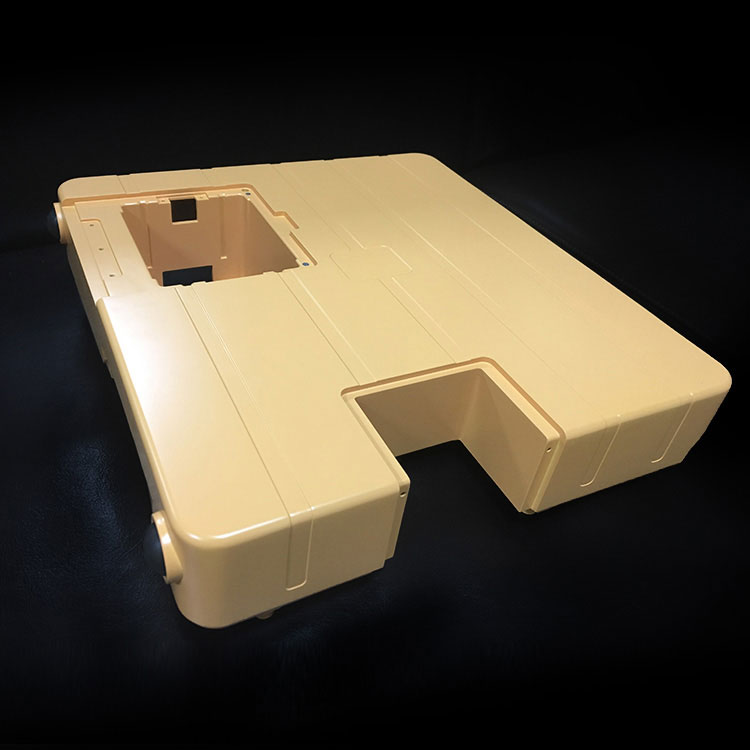

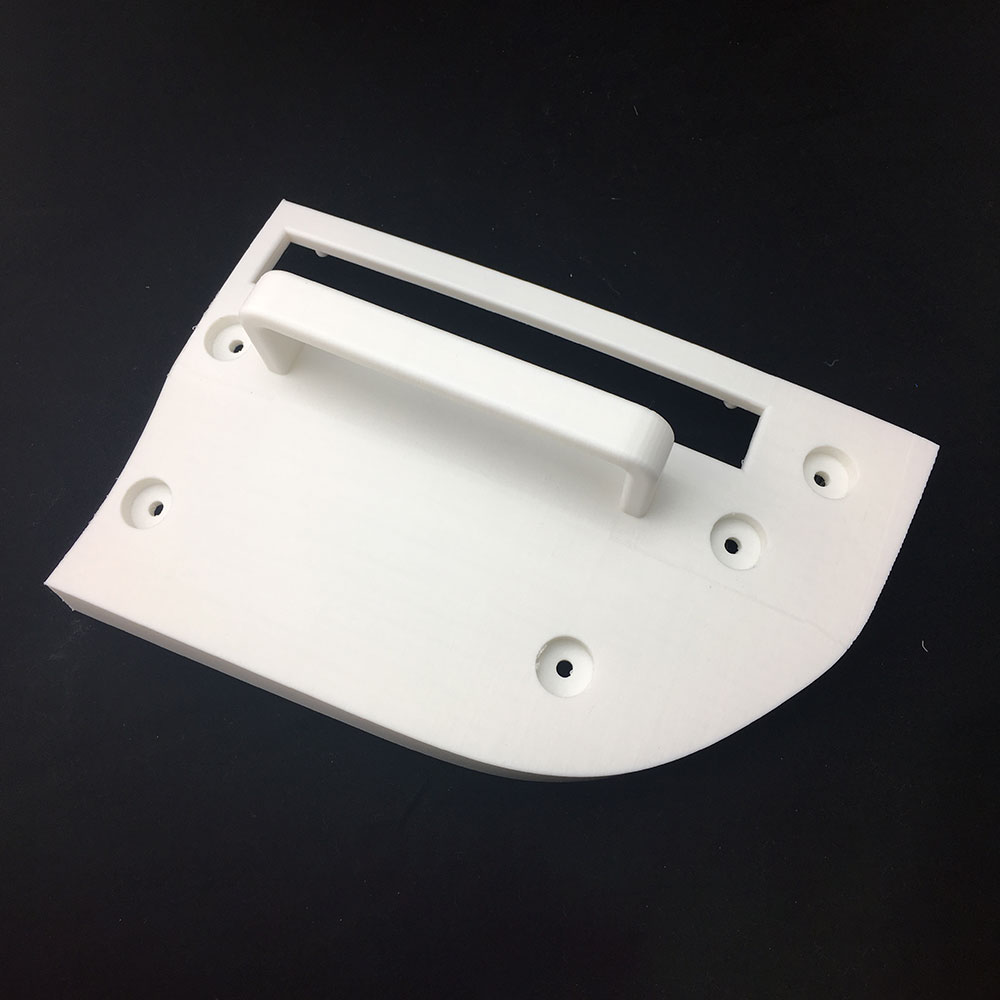

Holly specializes in Electronics Plastic Injection Molding, offering precision solutions for a range of electronic components. Our product categories include connectors, housings, circuit board enclosures, and battery covers. Specific items include LED light housings, power supply casings, sensor enclosures, and switch panels. Using advanced molding technology and high-performance materials, we ensure durability, lightweight designs, and reliable performance for all your electronic product needs.

Electronics Plastic Injection Molding Capabilities

Explore Our Latest Electronics Plastic Injection Molding Products

Discover the precision and quality of our latest electronics plastic injection molding products. With over 20 years of engineering expertise and thousands of successful projects, we deliver high-precision components that meet the toughest industry standards.

Electronics Plastic Injection Molding Materials Available

| ABS

ABS (Acrylonitrile-Butadiene-Styrene) is ideal for Electronics Plastic Injection Molding due to its excellent impact resistance, mechanical strength, and ease of processing. It is commonly used for durable, lightweight electronic housings, connectors, and covers. Examples include mobile phone cases, computer parts, and power tool housings, offering robust protection and precise molding. ABS’s low processing temperature and reliable performance make it a cost-effective choice for high-quality production.

|

|

| PP

PP (Polypropylene) is a versatile material for Electronics Plastic Injection Molding due to its excellent chemical resistance, lightweight nature, and high durability. It is ideal for components that require resistance to wear and low moisture absorption. PP is commonly used for electronic applications like battery casings, connectors, and cable management systems, where its lightweight and cost-effectiveness provide significant benefits.

|

|

| PC

PC (Polycarbonate) is ideal for Electronics Plastic Injection Molding due to its high strength, transparency, and excellent impact resistance. It withstands high temperatures and offers superior durability, making it perfect for electronic housings and parts that require both toughness and clarity. PC is commonly used for items like LED light covers, computer monitor housings, and power supply enclosures, where both mechanical strength and optical clarity are essential.

|

|

| PE

PE(Polyethylene ) is ideal for Electronics Plastic Injection Molding due to its excellent chemical resistance, low friction, and good electrical insulating properties. It is lightweight, flexible, and resistant to moisture, making it suitable for a wide range of electronic applications. PE is commonly used in cable insulation, electrical connectors, and battery components, offering durability and cost-efficiency in production.

|

|

| PBT

PBT (Polybutylene Terephthalate) is an ideal material for Electronics Plastic Injection Molding due to its excellent dimensional stability, high heat resistance, and low moisture absorption. It provides superior electrical insulation and chemical resistance, making it perfect for electronic components. PBT is commonly used in connectors, circuit board housings, and sensors, offering high durability and performance in electronic applications.

|

|

| PA

PA (Nylon) is an ideal material for Electronics Plastic Injection Molding due to its excellent mechanical strength, wear resistance, and low friction. It also provides good electrical insulation and can withstand harsh environments. PA is commonly used in electronic connectors, switches, and circuit breaker housings, offering high durability and reliability in demanding applications.

|

|

| POM

POM (Polyoxymethylene), also known as Acetal, is an ideal material for Electronics Plastic Injection Molding due to its high stiffness, low friction, and excellent wear resistance. It offers great dimensional stability and chemical resistance, making it perfect for precision components. POM is commonly used in electronic connectors, gears, switches, and housings, ensuring high durability and reliable performance in electronic devices.

|

|

| PET

PET (Polyethylene Terephthalate) is a highly durable and dimensionally stable material ideal for Electronics Plastic Injection Molding. It offers excellent strength, heat resistance, and low moisture absorption. PET is widely used for components like connectors, circuit board housings, and battery covers, where reliability and electrical insulation are key.

|

|

| TPE

TPE (Thermoplastic Elastomer) is ideal for Electronics Plastic Injection Molding due to its excellent flexibility, durability, and electrical insulation properties. It combines the advantages of rubber with the ease of thermoplastics, making it perfect for components requiring softness and elasticity. TPE is commonly used in sealing rings, gaskets, and flexible connectors, offering both performance and comfort in electronic devices.

|

|

| LCP

LCP (Liquid Crystal Polymer) is ideal for Electronics Plastic Injection Molding due to its outstanding thermal stability, electrical insulating properties, and low moisture absorption. LCP can withstand high temperatures and harsh environments, making it suitable for precision components. It is commonly used in connectors, IC carriers, and high-performance housings, offering excellent mechanical strength and reliability in demanding electronic applications.

|

|

Electronics Plastic Injection Molding Finishing Options

| Name | Description | Can be Applied with |

|---|---|---|

| Sandblasting | Sandblasting provides a uniform matte finish, enhancing texture and removing surface defects. | Plastic and metal parts |

| Polishing | Polishing gives a smooth, mirror-like finish, improving the aesthetic appeal of parts, especially for high-visibility components. | Plastic, metal, and resin parts |

| Heat Transfer Printing | Heat transfer printing allows for high-precision printing of logos, symbols, and labels on parts, commonly used for branding. | Plastic parts |

| Spray Coating | Spray coating adds durability, texture, and color, offering a range of finishes from glossy to matte. | Plastic parts |

| Texturing | Texturing provides specific patterns or textures on the surface for aesthetic or functional purposes, such as reducing glare. | Plastic parts |

| Laser Etching | Laser etching precisely engraves detailed patterns or text onto the surface, offering a durable, high-precision finish. | Plastic and metal parts |

| E-coating | Electrophoretic coating (E-coating) enhances the corrosion resistance and appearance of metal components, providing a durable finish. | Metal parts |

Electronics Plastic Injection Molding FAQs

Electronics Injection Molding – Ultimate FAQ Guide

In the following guide, you will know everything about Electronics Injection Molding.

Electronics Plastic Injection Molding -Definitive Guide

As a professional electronics plastic injection molding supplier in China, Holly can be a extension of your company’s manufacturing department. Holly provides high-quality electronics injection molding service, it ranges from product design and development to rapid prototyping and molds, customized plastic injection molding, sheet metal manufacturing, full-service machining, component procurement and supplier management, sub-assembly components or entire product assembly. Just send your drawings, we will design the moulds for you, all of our products are customized.

In the last 20 years, Holly has provided high-quality electronics injection molding service for different consumer electronics, such as electronic plastic parts, such as electronic plastic casing, host computer, keyboard maker, mouse shell, monitor, adapter socket cover, LED lighting cover, remote controller, router casing, computer plastic components, printer machine plastic parts, speaker accessories etc.

[lwptoc skipHeadingLevel=”h1,h2,h3,h4″]

1. Consumer Electronics Mould We Make For Our Clients

|

Plastic Injection Mold for Hair Dryer | Plastic material: ABS Steel of Cavity & Core: S136 Steel of Mould base: S50C. LkM standard Hardness of Cavity & Core: 48-52HRC Hardness of Wear Parts: 55-60HRC Core pulling system: Motor /oil cylinder/ stripping plate Mould Accessories: DME/HASCO Standard Cooling system: In core baffle cooling and in cavity plate chain drilling type cooling Surface finish: Diamond polish Molding life: 500, 000shots Runner: Cold Delivery time: 40work days |

|

Hair dryer mouth mold | Material: PA66+15% Mold life time: 1,000,000 Computer software: CAD, UG, ProE,SolidWorks,etc. Main service: Prototypes, Mold design, Mold making, Mold tesing, low/ high volume plastic production Raw material: PP,PA6,PLA,AS,ABS,PE,PC,POM,PVC, PET,PS,TPE/TPR etc Mold base material: P20, S45C, S50C etc. Cavity & Core material S136,718,2378,2316,4CR13,S50C, P20, H13, NAK80 etc. Hot runner: Syventive, Incoe, Yudo, etc. Mold standard: DME, HASCO, LKM, etc. |

|

Plastic Injection Mold for Computer Mouse | Mold core and cavity steel: P20,718,718H,738H,H13,NAK80,SKD61,2738,2316,S136,etc. Mold base steel: LKM, HASCO, DME, etc. Design software: UG, Pro-E, Solidwork, Moldflow, AutoCAD,etc. Molding Material: PP, PE, ABS etc as per customer demand Hot Runner brand: Mold Master,Incoe,Yudo,Hasco,Syventive etc Delivery time: 35-45 days Mold life: 300,000-1,000,000shots |

|

Camera housing injection mold | Material: ABS Mold life time: 1,000,000 Computer software: CAD, UG, ProE,SolidWorks,etc. Main service: Prototypes, Mold design, Mold making, Mold tesing, low/ high volume plastic production Raw material: PP,PA6,PLA,AS,ABS,PE,PC,POM,PVC, PET,PS,TPE/TPR etc Mold base material: P20, S45C, S50C etc. Cavity & Core material: S136,718,2378,2316,4CR13,S50C, P20, H13, NAK80 etc. Hot runner Syventive, Incoe, Yudo, etc. Mold standard: DME, HASCO, LKM, etc |

|

cpu fan blade injection mould | Material: PA66+15% Mold life time: 1,000,000 Computer software: CAD, UG, ProE,SolidWorks,etc. Main service: Prototypes, Mold design, Mold making, Mold tesing, low/ high volume plastic production Raw material: PP,PA6,PLA,AS,ABS,PE,PC,POM,PVC, PET,PS,TPE/TPR etc Mold base material: P20, S45C, S50C etc. Cavity & Core material: S136,718,2378,2316,4CR13,S50C, P20, H13, NAK80 etc. Hot runner: Syventive, Incoe, Yudo, etc. Mold standard: DME, HASCO, LKM, etc. |

|

ABS/PC Carbon Fiber Material Plastic Injection Mold for Camera Housing | Mould base material: LKM, LYM standard etc Mould spare parts material: HASCO, DME etc Hardness of steel: 32-52HRC Mould design: 3D/2D drawings Runner: hot / cold runner system Mold Steel: P20, S136, H13, 718H, NAK80 etc. |

|

Plastic Injection Mold for Electronic Station Cover | Mold base standards: LKM EQV Parts material: Plastic Material: PC LEXAN ML4539 PER FAR 25.853, BLACK Product Name: Plastic Injection Mold Mold Base: LKM, HASCO, DME, etc. Mold Cavity: Single, Multi, Family Molding Material: ABS, PC, PP, PE, PA, PS, +GF, POM, PMMA, etc. Color: Transparent, solid color according to your requests Surface: Textured, glossy or mirror polished, printing, planting, ect. Computer Software CAD, UG, ProE, SolidWorks, etc Mold Material: S50C, P20, S136, S136H, 718, 718H, 2738, 738H etc. Mold Life: 300,000~1,000,000 cyces based on demand Runner: Cold Runner; Hot runner such as YUDO, MASTER, SYNVENTIVE etc. |

|

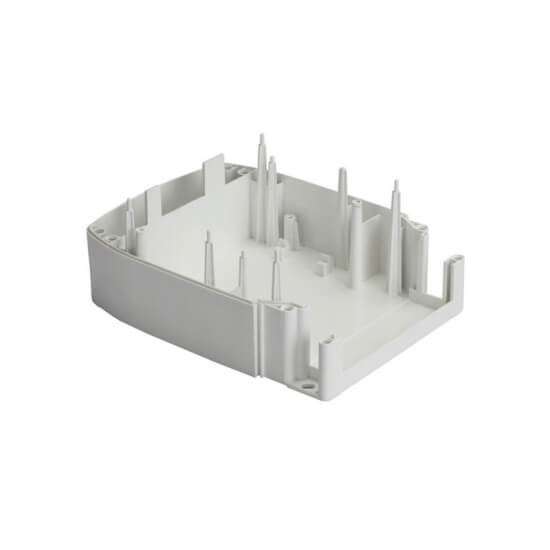

ABS Plastic Electronic Enclosure Injection Mold | Mold Base: LKM, HASCO, DME, etc. Mold Cavity: Single, Multi, Family Molding Material: ABS, PC, PP, PE, PA, PS, +GF, POM, PMMA, etc. Color: Transparent, solid color according to your requests Surface: Textured, glossy or mirror polished, printing, planting, ect. Computer Software CAD, UG, ProE, SolidWorks, etc Mold Material: S50C, P20, S136, S136H, 718, 718H, 2738, 738H etc. Mold Life: 300,000~1,000,000 cyces based on demand Runner: Cold Runner; Hot runner such as YUDO, MASTER, SYNVENTIVE etc. |

|

Customized plastic mold for ABS plastic shell for scanner from China Supplier | Material: ABS Mold life time: 1,000,000 Computer software: CAD, UG, ProE,SolidWorks,etc. Main service: Prototypes, Mold design, Mold making, Mold tesing, low/ high volume plastic production Raw material: PP,PA6,PLA,AS,ABS,PE,PC,POM,PVC, PET,PS,TPE/TPR etc Mold base material: P20, S45C, S50C etc. Cavity & Core material S136,718,2378,2316,4CR13,S50C, P20, H13, NAK80 etc. Hot runner: Syventive, Incoe, Yudo, etc. Mold standard :DME, HASCO, LKM, etc. |

|

Plastic Injection Television TV Remote Control Enclosure Housing Shell Mould | Material: ABS Mold life time: 1,000,000 Computer software: CAD, UG, ProE,SolidWorks,etc. Main service: Prototypes, Mold design, Mold making, Mold tesing, low/ high volume plastic production Raw material: PP,PA6,PLA,AS,ABS,PE,PC,POM,PVC, PET,PS,TPE/TPR etc Mold base material: P20, S45C, S50C etc. Cavity & Core material S136,718,2378,2316,4CR13,S50C, P20, H13, NAK80 etc. Hot runner: Syventive, Incoe, Yudo, etc. Mold standard: DME, HASCO, LKM, etc. |

|

Customized Plastis Injection Mold for Router Cover | Material: ABS Mold life time: 1,000,000 Computer software: CAD, UG, ProE,SolidWorks,etc. Main service: Prototypes, Mold design, Mold making, Mold tesing, low/ high volume plastic production Raw material: PP,PA6,PLA,AS,ABS,PE,PC,POM,PVC, PET,PS,TPE/TPR etc Mold base material: P20, S45C, S50C etc. Cavity & Core material: S136,718,2378,2316,4CR13,S50C, P20, H13, NAK80 etc. Hot runner: Syventive, Incoe, Yudo, etc. |

|

ABS Electronic Shell Plastic Molding Parts | Mold Base: LKM, HASCO, DME, etc. Mold Cavity: Single, Multi, Family Molding Material: ABS, PC, PP, PE, PA, PS, +GF, POM, PMMA, etc. Color: Transparent, solid color according to your requests Surface: Textured, glossy or mirror polished, printing, planting, ect. Computer Software CAD, UG, ProE, SolidWorks, etc Mold Material: S50C, P20, S136, S136H, 718, 718H, 2738, 738H etc. Mold Life: 300,000~1,000,000 cyces based on demand Runner: Cold Runner; Hot runner such as YUDO, MASTER, SYNVENTIVE etc |

|

ABS PC Electronic Plastic Parts Housing by Injection Overmoulding Mold | Mould Material: 45#, 50#, P20, H13, 718, 2738, NAk80, S136, SKd61 etc Mould Base: LKM, HASCO etc. Cavity: Single/multi Runner: Hot/cold Mould Design: 3D/2D Drawing Design Days: 3 days Design Software: UG, PROE, CAD, CAE, CAM, CAXA ect Plastic Material: PP, PC, PS, PE, PU, PVC, ABS, PMMA etc Mo uld Life: 300, 000-3, 000, 000 shots Injection System: Pin-point-gate Polish System: Mirror Polish Delivery Time: 15-60days |

|

Plastic Molding of Printer top cover | Mold Base: LKM, HASCO, DME, etc. Mold Cavity: Single, Mult, Family Molding Material: ABS, PC, PP, PE, PA, PS, +GF, POM, PMMA, etc. Color: Transparent, solid color according to your requests guests Surface: Textured, glossy or mirror polished, printing, planting, ect. Design software: PRO/E, Solidwork, UG, Moldflow, AutoCAD, etc Mold Material: S50C, P20, S136, S136H, 718, 718H, 2738, 738H etc. Mold Life: 300,000~1,000,000 cyces based on demand Runner: Cold Runner; Hot runner such as YUDO, MASTER, SYNVENTIVE etc. |

|

Plastic Molding of speaker enclosure | Mold Base: LKM, HASCO, DME, etc. Mold Cavity: Single, Mult, Family Molding Material: ABS, PC, PP, PE, PA, PS, +GF, POM, PMMA, etc. Color: Transparent, solid color according to your requestsuests Surface: Textured, glossy or mirror polished, printing, planting, ect. Design software: PRO/E, Solidwork, UG, Moldflow, AutoCAD, etc Mold Material: S50C, P20, S136, S136H, 718, 718H, 2738, 738H etc. Mold Life: 300,000~1,000,000 cyces based on demand Runner: Cold Runner; Hot runner such as YUDO, MASTER, SYNVENTIVE etc. |

|

Set Top Box Mold Plastic Injection Tooling | Mould Material 45#, 50#, P20, H13, 718, 2738, NAk80, S136, SKd61 etc Mould Base: LKM, HASCO ect. Cavity: Single/multi Runner: Hot/cold Mould Design: 3D/2D Drawing Design Days: 3 days Design Software: UG, PROE, CAD, CAE, CAM, CAXA ect Plastic Material: PP, PC, PS, PE, PU, PVC, ABS, PMMA ect Mould Life: 300, 000-3, 000, 000 shots Injection System: Pin-point-gate Polish System: Mirror Polish Delivery Time: 15-60days |

|

Plastic Electronic Circuit Board Retainer Injection Mould | Plastic Material: ABS Mold Base: LKM, HASCO, DME, etc. Mold Cavity: Single, Mult, Family Hardness of Cavity & Core: 48-52HRC Hardness of Wear Parts: 55-60HRC Core Pulling System: motor / oil cylinder / stripping plate Cooling system: In core baffle cooling and in cavity plate chain drilling type cooling Surface finish: Diamond polish Mould Life: 1,000,000 shots Runner: Cold Computer Software: CAD, UG, ProE,SolidWorks,etc. Main Service: Prototypes, Mold design, Mold making, Molding testing, Low volume/ high volume plastic production Delivery time: 40 working days |

|

Unique Plastic Bracket Injection Mold | Mold Base: LKM, HASCO, DME, etc. Mold Cavity: Single, Mult, Family Molding Material: ABS, PC, PP, PE, PA, PS, +GF, POM, PMMA, etc. Color: Transparent, solid color according to your requests Surface: Textured, glossy or mirror polished, printing, planting, ect. Mold Material: S50C, P20, S136, S136H, 718, 718H, 2738, 738H etc. Mold Life: 300,000~1,000,000 cyces based on demand Runner: Cold Runner; Hot runner such as YUDO, MASTER, SYNVENTIVE etc. |

|

Bluetooth Speaker Louder Box Music Box injection mould | Material: ABS Mold lifetime: 1,000,000 Computer software: CAD, UG, ProE,SolidWorks,etc. Main service: Prototypes, Mold design, Mold making, Mold testing, plastic production Mold base material: P20, S45C, S50C etc. Cavity & Core material: S136,718,2378,2316,4CR13,S50C, P20, H13, NAK80 etc. Hot runner: Syventive, Incoe, Yudo Mold standard: DME, HASCO, LKM, etc. |

|

Plastic Mould for Wall Mount Dome CCTV Camera | Mold Base: LKM, HASCO, DME,etc. Mold Cavity: Single, Mult, Family Molding Material: ABS, PC, PP, PE, PA, PS, +GF, POM, PMMA,etc. Colour: Transparent, solid colour according to your requests guests Surface: Textured, glossy or mirror polished, printing, planting. Design software: PRO/E.Solidwork,UG.Moldflow.Autocad,etc Mold Material: S50C, P20, 718, 718H, 2738, 738H etc. Mold Life: 300,000~1,000,000 cycles according to your requests Runner: Cold Runner; Hot runner such as YUDO, MASTER, SYNVENTIVE etc. |

[lwptoc skipHeadingLevel=”h1,h3″ skipHeadingText=”*Custom Electronics Plastic Injection Molding Solutions|*Grille Mould|*Console Board Mold|*Door Trim Mould|*Fender Mould|*Bumper Mould|*Gear Shift Cover Mould|*Featured Electronics Components We Produced|*Electronics Plastic Injection Molding Capabilities|*Explore Our Latest Electronics Plastic Injection *Molding Products|*Electronics Plastic Injection Molding Materials Available|*Electronics Plastic Injection Molding Materials Available|*Electronics Plastic Injection Molding Finishing Options|*Electronics Plastic Injection Molding FAQs|*Electronics Injection Molding – Ultimate FAQ Guide|*Electronics Plastic Injection Molding -Definitive Guide|*Custom Electronics Plastic Injection Molding Solutions|*Grille Mould|*Console Board Mold|*Door Trim Mould|*Fender Mould|*Bumper Mould|*Gear Shift Cover Mould|*Featured Electronics Components We Produced|*Electronics Plastic Injection Molding Capabilities|*Explore Our Latest Electronics Plastic Injection Molding Products|*Electronics Plastic Injection Molding Materials Available|*Electronics Plastic Injection Molding Materials Available|*Electronics Plastic Injection Molding Finishing Options|*Electronics Plastic Injection Molding FAQs|*Electronics Injection Molding – Ultimate FAQ Guide|*Electronics Plastic Injection Molding – Definitive Guide”]

2. Benefits of Injection Molding for the Production of Electronics Parts

Obviously, injection molding electronics is a great way to produce electronics components in China , itwill offer you optimal benefits for your consumer electronics. Plastic injection molding is an efficient manufacturing process already, yet it becomes a lot more evident via the lots of advantages that locate their means into the production of different sorts of parts– such as those that are utilized for electronics.

Keep in mind that molding business in China promote the very best requirements in top quality and also quantity in order to fulfil the demands of the electronic age today. This is even more reason why you should collaborate with them. For more of this, see the benefits noted here to assist you to understand the capabilities of this manufacturing process.

Comprehensive Features & Surface Quality

Using plastic injection molding as a manufacturing procedure will certainly imply that you are likely to get highly maximized products from the service. Given this, anticipate that the products will have one of the most in-depth attributes and complicated frameworks. Electronics parts are made to promote criteria produced the information and design in its entirety which a molding firm in China will certainly be greater than satisfied to fit.

Information Technology Equipment (ITE) is called for to have an outstanding ability to hold up against pressure. Because of this demand, the production procedure is observed in order to style as well as manufacture it according to its objective.

Design Accuracy

ITEs can come in several kinds. Whether it is a Central Processing Unit (CPU), a display, or a computer mouse, they are all produced with convenience as well as marked style precision. Solutions such as assembly, packaging, quality control records, and also item style, can all be provided by the capacities in plastic injection molding. Whether the preferred surface area effect of an item is mirror brightened, combed polished, glossy, or matte, whatever it is, the benefit of mold making is still there.

High-Efficiency

Plastic injection molding in China satisfies customer specs that are essential to make a manufacturing job a success. Electronics screen housing, laptop computer base covers, electronics mouse housing, or any type of other electronics part– name it as well as the team of professional makers will be up to the work of making it with high performance.

High performance is attained by the different product services that will be used such as overmolding, insert molding, material shot molding, and much more. The need for these components will certainly not prevent inexpensive objectives in manufacturing. High manufacturing result prices do not impact the cost-effectiveness of this type of making process which is even more factor to contact an injection mold company today.

Enhanced Strength & Durability

The digital age has raised the need for electronics components, but the amount required still does not compromise the degree of top quality that is required for the results of production. Solid as well as resilient options for this market will be enabled by effective molding processes. Greater toughness for electronics parts would certainly imply that it can supply lasting satisfaction for the user that eventually develops efficiency.

Although there are other molding procedures that provide the exact same purpose for this sort of item, plastic injection molding for electronic is still the prime player in this market. What you need to find out about this market is that the group of layout experts, as well as designers, are experienced concerning the international grades as well as requirements that are necessary when benefiting components such as ITEs.

Price in Automation

While plastic injection molding for consumer electronicsis an automatic process, it does a great deal greater than quicken manufacturing– it improves the cost-effectiveness. The reduction of making expenses is considerably really felt which makes it simpler for services to incorporate this production process.

The automation of plastic injection molding implies that cost-effectiveness comes from the decrease of costs pertaining to the workforce. The increase in demand for electronic components requires cost-effectiveness in the production process, which is what plastic injection molding can serve you. Utilizing Electronics Aided Design (CAD) as well as Electronics Aided Manufacturing (CAM) enables this need to be possible.

Sustainable Manufacturing Process

The advantage of utilizing electronics injection molding is that it utilizes sustainable techniques to attain the product layout that you want. With waste-minimizing technology, initiatives for advancement, as well as air pollution reduction, mold-making is one of the leading markets to maximize its efforts to decrease the carbon footprint in the environment. Electronics components will be generated at high quantity amounts and also optimum top quality so it would be fantastic if your partner injection mold company is doing what they can in order to have a lasting production process.

Versatility in Parts Improvement

The affordable sector of electronics injection molding results in high requirements for molding business. Designers of electronic devices parts, as well as various other applications, make it an indicate employ state-of-the-art manufacturing methods to remain appropriate out there.

If you are intending on collaborating with a plastic injection mold manufacturer, then you must recognize that having the flexibility for components improvement goes a long way for your task. This flexibility is responsible for products that can hold qualities such as warmth as well as impact resistance which will significantly offer its function if it is going to be utilized for the manufacturing of electronics parts. With this, efforts to enhance colourability, ignition resistance, and also UV stability is significantly taken into consideration which is what you are most likely to need for this type of application.

Secret Takeaway

These are just some key benefits of mold making for the manufacturing of electronics parts which you can additionally receive when you Advantages of Mold Making for the Production of Electronics Parts

What are the benefits of electronics plastic injection molding in the production of electronic devices parts?

- Thorough attributes and surface area top quality

- Layout accuracy

- High-efficiency

- Boosted toughness and durability

- Affordability in automation

- Sustainable manufacturing procedure

- Versatility partly enhancement

Producing electronic devices components with the manufacturing procedure of injection mold in China will certainly give you optimal benefits for your item. Plastic injection molding is an efficient production process for electronics currently, however it becomes much more apparent with the lots of advantages that discover their method right into the manufacturing of different kinds of components– such as those that are utilized for electronics.

Remember that molding firms in China maintain the best requirements in top quality and quantity in order to satisfy the demands of the digital age today. This is even more reason why you should collaborate with them. For even more of this, see the benefits noted right here to help you recognize the capabilities of this production process.

Detailed Features and also Surface Quality

Utilizing electronics injection molding as a production procedure will certainly suggest that you are mosting likely to receive extremely maximized products from the solution. Given this, expect that the products will certainly have the most detailed features and complicated structures. Electronics components are made to support criteria made for the details as well as design in its entirety which a molding company in China will certainly be more than satisfied to fit.

Information Technology Equipment (ITE) is called for to have an exceptional capacity to stand up to stress. Due to this demand, the manufacturing procedure is observed in order to layout and make it according to its purpose.

Style Accuracy

Just take the computer parts as an example, ITEs can be available in lots of kinds. Whether it is a Central Processing Unit (CPU), a screen, or a computer mouse, they are all manufactured with versatility and also the designated layout precision. Providers such as assembly, packaging, quality control reports, and also product layout, can all be provided by the capabilities in plastic injection molding electronics. Whether the wanted surface effect of an item is mirror brightened, brushed polished, shiny, or matte, regardless of what it is, the benefit of mold production is still there.

High-Efficiency

Injection molds in China deal with customer specs that are essential to make a manufacturing job a success. Electronic devices display housing, laptop computer base covers, electronic devices mouse real estate or any kind of other electronic devices component– name it and the group of specialist suppliers will depend on the work of making it with high effectiveness.

High effectiveness is attained by the various item remedies that will be made use of such as overmolding, insert molding, material injection molding, as well as much more. The need for these parts will certainly not impede inexpensive purposes in manufacturing. High manufacturing outcome prices do not affect the cost-effectiveness of this kind of manufacturing process which is all the more reason to speak to an injection mold company today.

Enhanced Strength & Durability

The electronic age has actually raised the demand for electronics parts, but the amount called for still does not compromise the degree of high quality that is needed for the outcomes of manufacturing. Solid as well as long-lasting choices for this market will be enabled by effective molding procedures. Greater stamina for electronic devices components would suggest that it can give long-lasting complete satisfaction for the individual that inevitably builds efficiency.

Although there are other molding procedures that provide the very same function for electronics, plastic injection molding is still the prime player for this sector. What you need to understand about this industry is that the group of design experts and engineers are educated about the worldwide qualities as well as requirements that are needed when benefiting parts such as ITEs.

Cost in Automation

While electronics plastic injection molding is an automated process, it does a great deal more than accelerate production– it boosts the cost-effectiveness. The decrease of manufacturing costs is dramatically really felt which makes it less complicated for companies to integrate this production process.

The automation of plastic injection molding implies that cost-effectiveness comes from the reduction of expenses referring to the workforce. The rising need for electronics components calls for that cost-effectiveness is factored in the manufacturing process, and it can be provided by electronic plastic injection molding. Making Use Of Electronics Aided Design (CAD) and also Electronics Aided Manufacturing (CAM) allows this need to be feasible.

Sustainable Manufacturing Process

The advantage of using plastic injection molding is that it uses lasting techniques to attain the item layout that you desire. With waste-minimizing technology, initiatives for technology, and air pollution reduction, mold-making is just one of the leading industries to optimize their efforts to minimize the carbon impact in the setting. Electronics components will certainly be created at high quantity amounts as well as optimum high quality so it would certainly be fantastic if your companion injection mold company is doing what they can in order to have a sustainable manufacturing process.

Adaptability in Parts Improvement

The affordable industry of plastic injection molding causes high standards for molding business. Designers of electronic devices components and various other applications make it a point to use advanced manufacturing techniques to remain relevant in the market.

If you are intending on collaborating with a plastic injection mold maker, then you should recognize that having the flexibility for components improvement goes a long means for your job. This adaptability is accountable for items that can hold qualities such as warmth and also impact resistance which will greatly serve its purpose if it is mosting likely to be made use of for the manufacturing of electronic devices parts. With this, efforts to boost colour-ability, ignition resistance, as well as UV stability is substantially considered which is what you are going to need for this type of application.

3. Conclusion

These are just some of the important benefits of electronic injection molding, when you establish trustworthy cooperation with a plastic injection molding company, you can get these additional benefits. With the right style and ability, your work will be successful soon. Have a reliable mold business. With the best layout and performance intent, your work will surely succeed soon.