In-Mold Decorating Labels Molding Service

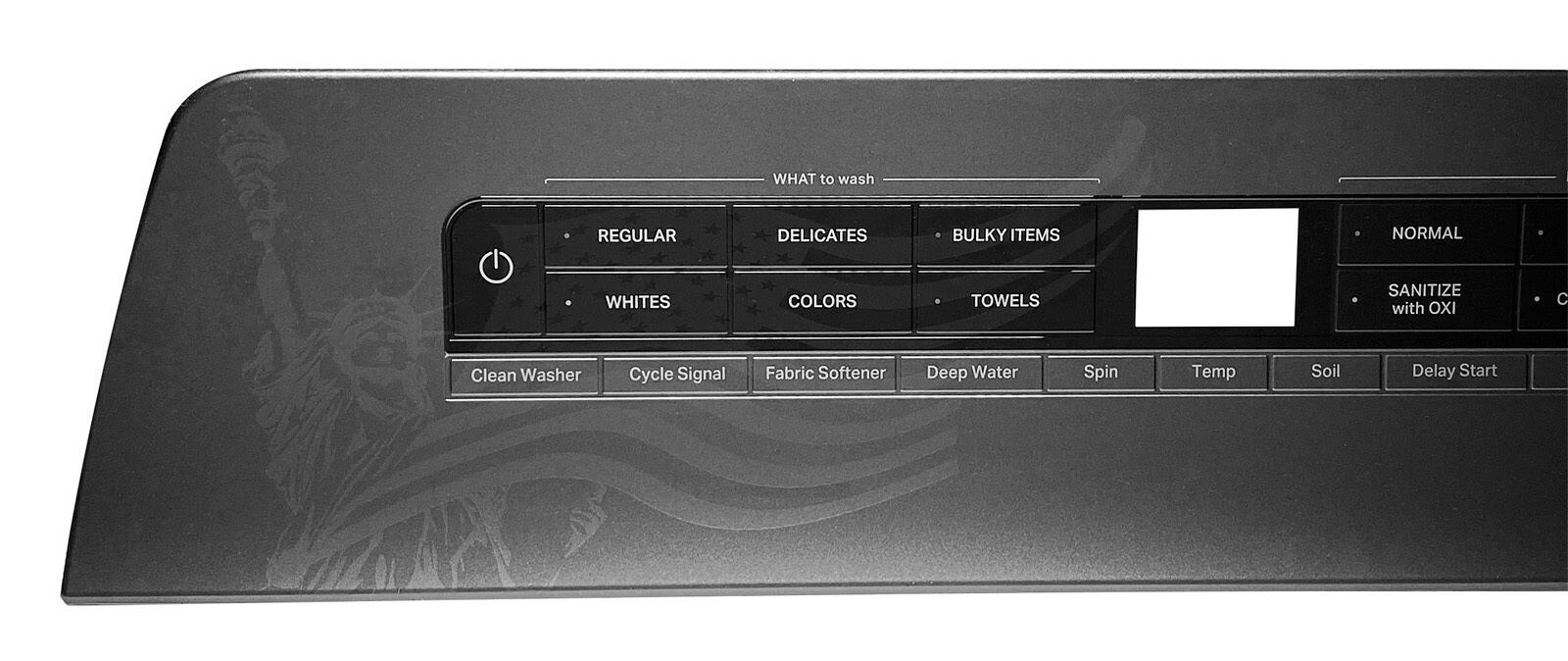

In-mold decoration (IMD) and in-mold labeling (IML) provides design flexibility and results that other processes cannot provide, and provide enhanced graphics to gain a competitive advantage in today’s market. Therefore, it is undoubtedly widely used in many industries. Holly has extensive experience in custom in-mold decoration (IMD) and in-mold labeling (IML) of all types and sizes. Our experts can help you choose the right tools and materials for your IMD application and provide on-site technology Support, including complete graphics and design services. From concept to delivery, Chemmar has competitive advantages in design, engineering, project management, manufacturing and internal molds. Holly provides customized in-mold decoration (IMD) and in-mold labeling (IML) services. IMD or IML are mainly used in industries such as automobiles, packaging, home appliances, and medical treatment.

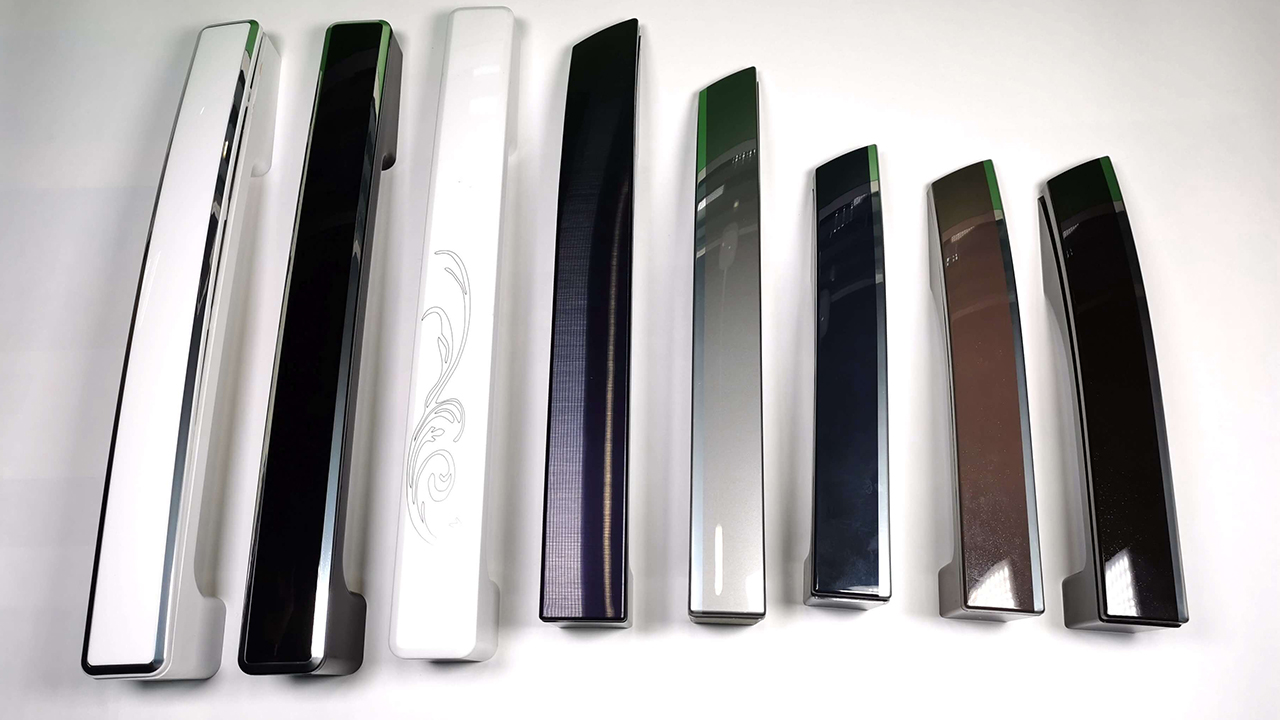

In Mold Decoration Parts

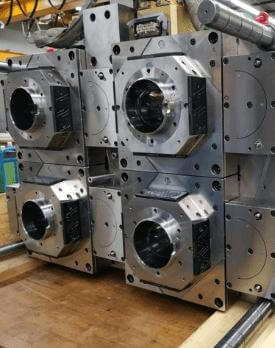

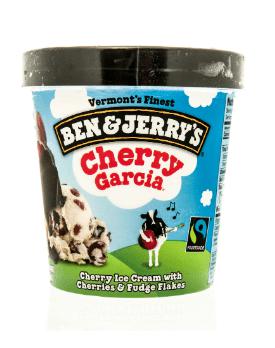

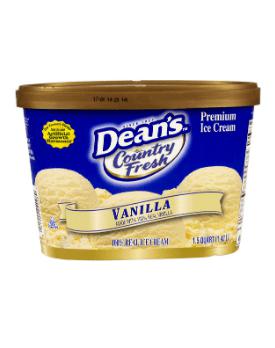

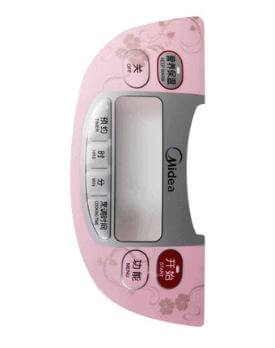

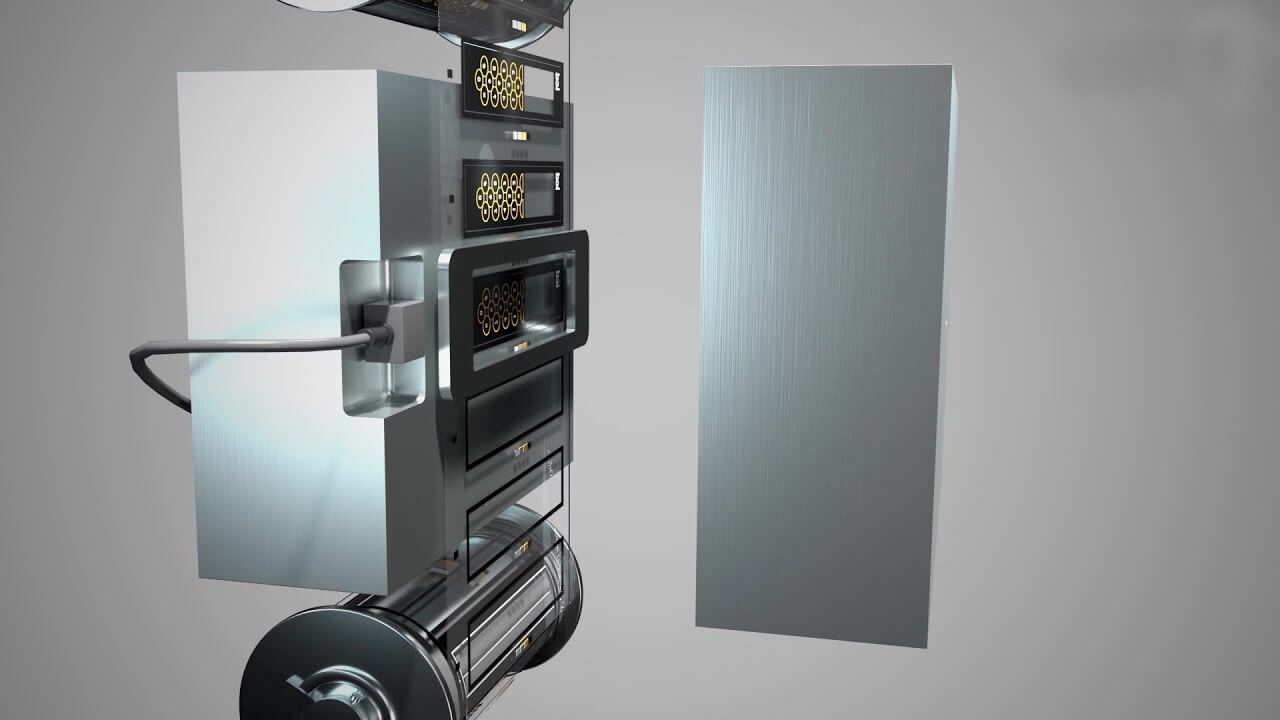

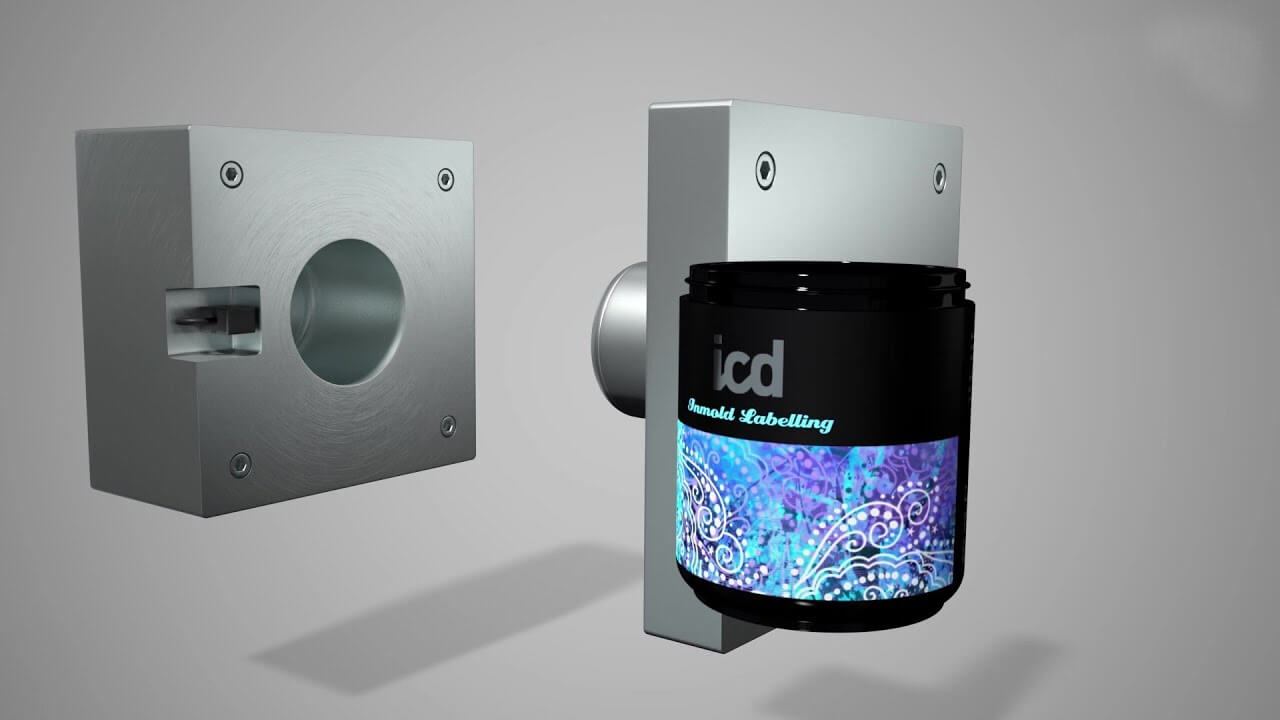

In-mold decoration (in-mold decoration, IMD) refers to the process of opening the mold, decorating the part, embedding graphics on the part, and completing the printing/decoration molding and transfer process. This process has been widely used in some industries. Holly would like to show you some pictures of our samples.

China In Mold Decoration Manufacturer FAQ

In Mold Decoration – Ultimate FAQ Guide

In the mold decoration, the surface of the product can be prevented from being scratched and rubbed, and the color can be kept bright for a long time, and the color is not easy to fade. It is applied to the surface of the film, through printing, high-pressure forming, and then placed in an injection mold to integrate it with the injection material.

Comer’s professional technical team is committed to the principle of customer service, providing the best solutions in a timely and efficient manner, providing perfect products, and helping customers win more market shares.

1. What is in-mold decoration?

The in-mold decoration is a product surface decoration process. The product has a hardened transparent film on the surface, with a printed pattern layer in the middle, an injection layer on the back, and ink in the middle.

In-mold decoration can make the product resistant to friction, prevent surface scratches, and can maintain bright colors for a long time. The simple understanding is: the decoration process can be completed in the injection mold.

2. What are the advantages of in-mold decoration?

The advantages of in-mold decoration products are as follows:

- Since the ink is between the plate and the injection material, the beautiful decorative painting and the logo are hidden. They will not disappear by friction or chemical corrosion.

- Graphics, text, logo, and color design can be changed at any time without changing the mold.

- The printing accuracy of 3d shape products is accurate, and the error is + 0.05mm.

- It can provide text, logo backlight, and high light-transmitting window effects.

- The function keys are evenly raised, feel good, and the life span can reach more than 1 million times.

- Three-dimensional changes can increase the designer’s degree of freedom in product design.

- The color is very bright.

3. Where can I apply for in-mold decoration (IMD) and in-mold labeling (IML)?

- Household appliances: control decorative panels for rice cookers, washing machines, microwave ovens, air conditioners, refrigerators, etc.;

- Electronics: MP3, MP4, calculator, VCD, DVD, electronic notebook, digital camera, and other decorative shells, color shells, and signs;

- Automobile industry: instrument panels, air conditioning panels, interior parts, lampshades, signs, etc.

- Computer industry: keyboard, mouse, face shell;

- Communication: mobile phone buttons, mobile phone lenses, mobile phone color shells, PHS and fixed-mobile phone panels, window frame lenses;

- Other industries: medical equipment, cosmetic boxes, decorative boxes, toys, sports and leisure supplies and more.

4. What are the advantages of in-mold decoration?

The advantages of in-mold decoration are as follows:

- In-mold decoration inlay injection molding technology is widely used in communications,

- Household appliances, electronics, automobiles, instrumentation, medical equipment, toys, cosmetics and other industries.

- The in-mold decoration is a new type of plastic decoration technology.

- It can change three-dimensionally, increase the freedom of the designer, and design a variety of personalized products to meet the needs of the times.

- In-mold decoration technology can realize the integration of injection molding and decoration,

- Once completed, you can also create various special effects, such as button bubbles,

- Metal mirror or smooth surface, metal wire drawing, backlight breathability, concave and convex dot patterns, etc., very decorative and functional.

- In-mold decoration technology is the best new technology to replace paint spraying and electroplating of plastic products, reducing the subsequent injection molding process, and promoting it in the plastic industry, which can truly realize the significance of energy saving and environmental protection.

- It will bring huge economic and environmental benefits to society and enterprises.

- Reduce process cost: only need to open a set of molds, you can reduce costs and labor,

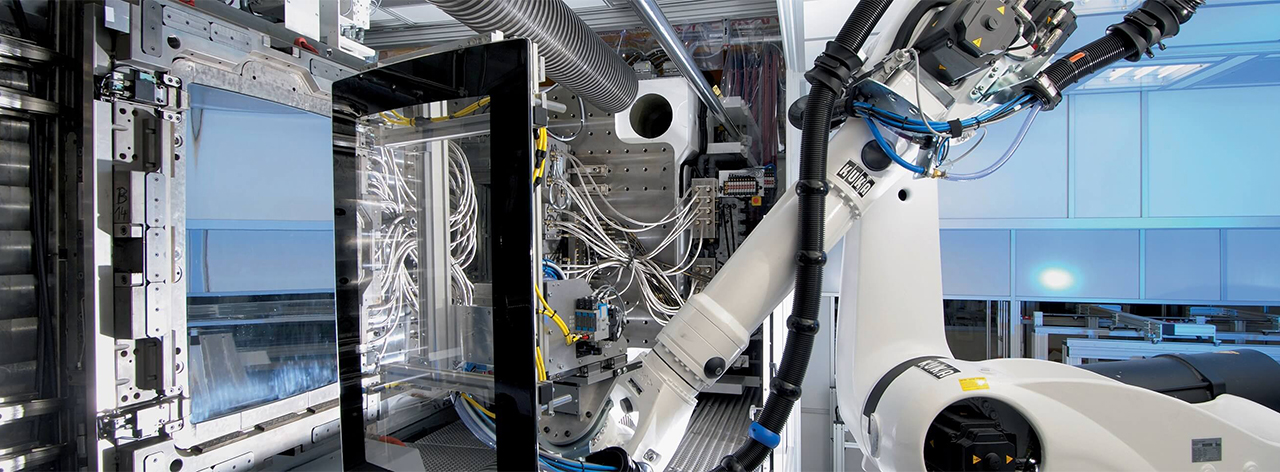

- High degree of production automation, simplified process flow, one-time injection molding process,

- Modeling and decoration are realized at the same time.

- Reduce the impact on the environment: The technology is green and environmentally friendly, avoiding the pollution caused by traditional painting and electroplating.

5. What are the technical characteristics of in-mold labeling (IML)?

The technical characteristics of in-mold labeling (IML) are as follows:

- The surface is a hardened transparent film, and the middle is a printed pattern layer,

- The back side is a plastic layer, because the ink is sandwiched in the middle, it can prevent the surface from scratching and abrasion, and can keep the color bright and not fading for a long time.

6. What are the technical characteristics of the forming roll?

The process characteristics of the forming roll are as follows:

On the forming roller is the pattern printed on the film, the mold cavity of the diaphragm, and plastic film feeder is suitable for injection molding. After the ink layer and film are separated in the case of injection molding, the surface of the plastic parts and plastic parts of the ink layer is not transparent protective film on the surface of the final product.

The diaphragm is only a carrier of the production process. However, the advantages of the inner mold roller are the high degree of production automation and the low cost of mass production.

7. What is the difference between the process of in-mold label and in-mold roller?

The process differs between the in-mold label and the in-mold roller is as follows:

Between the two processes, the biggest difference is whether a transparent protective film covers the product’s surface.

8. What is the difference between IMR/IML and IMF?

The differences between IMR/IML and IMF are as follows:

- IMR: mobile phone shell, tablet shell, home appliance shell

- Bottle label, food box

- IMF: some irregular items

9. What are the disadvantages of in-mold rollers?

The disadvantages of in-mold rollers are as follows:

Surface of the product has only a few microns of printed pattern. After the product is used for a period of time, the printed pattern layer is easy to wear and fade.

In addition, the new product development cycle is long, the development cost is high, and the pattern color cannot be flexibly changed in small batches.

10. What is the process of in-mold labeling (IML)?

The in-mold labeling (IML) process is as follows:

- Cutting the material.

- Plane printing.

- The ink is dry and fixed.

- Stick protective film.

- Punching and positioning holes.

- Thermoforming.

- Cut the shape of the edge.

- Material injection molding.

11. What are the advantages of the IMR process?

- Integrated molding, simplifying the production process, reducing production/inventory costs and manpower, shortening the product manufacturing cycle, and improving production efficiency.

- Various reliability tests are at the highest level in the industry to ensure product stability and durability.

- Highly automated production to ensure the stable production of high-quality products.

- Use automatic printing and environmentally friendly ink to meet environmental protection requirements.

- Multi-color printing, wood grain, carbon fiber, metallic colors, etc. The surface texture and pit pattern of the product can be colored at the same time.

12. What is the process of in-mold decoration?

- Membrane transportation

- Film positioning

- Take the module

- Injection

- Post-processing,

- Cleaning flash

13. What are the disadvantages of In-Mold decoration?

- In-mold decoration is not suitable for small or unstable products.

- There is always a long development cycle, especially when you encounter the feasibility of matching process changes or problem changes.

- This cycle often leads to delays in the progress of the entire project.

- The development cost is high, and it is difficult to control the cost of raw materials.

- Rework, repair, and defective products can only be discarded.

- The cost of failed production is high.

14. What are the application advantages of UV curing ink in-mold decoration technology?

- Automatic printing, high production efficiency;

- UV ink curing takes only a few seconds or more than ten seconds, and the curing speed is very fast;

- It can screen print finer lines with high resolution, thin ink layer, and large printing area;

- Before injection molding, if UV ink imprinting is not applied, there will be no “flying oil” phenomenon of imprinting ink.

- The entire operating system is easy to control. Because the amount of solvent is small, UV ink does not require long solvent evaporation or drying process. Therefore, during injection, the ink heating will not produce a “flying oil” phenomenon.

15. What are the process steps for in-mold decoration?

The process steps of in-mold decoration are as follows:

- Position the printing film holder (roller label) within the reach of the mold.

- Clamp and adjust the film frame by clamping frame and vacuum.

- The mold is closed and the injection cycle begins.

- The lacquer layer of the substrate film is combined due to the prevailing pressure and temperature.

- The finished product is taken off, and the film is given the next cycle at the same time.

16. What is the process of in-mold decoration?

The process of in-mold decoration is as follows:

- Place the in-mold labels (front and rear labels) in the label box in advance.

- When the mold is opened, the plastic container is formed, and the label and the container are integrated.

- With the opening of the mold, the robot will suck up the front and rear labels.

- Place the printed label facing inward and the solid glue facing outward on both sides of the mold. The vacuum holes on the mold will firmly stick the label on the mold.

- When the raw material of the plastic container is heated and sags into a hose, the mold and the label are quickly closed, and in order to bring the hose close to the mold wall, air is blown into it. Next to the prototype container, the solid adhesive on the label began to melt and adhere to the plastic container.

17. Why choose Holly as an in-mold decoration supplier?

- Holly can meet your current part specifications, reduce operating costs, and simplify the production process.

- Help you achieve the results you want.

- Holly can provide free advice for your IMD project.

For any inquiries about in-mold decoration, please feel free to contact Holly.

18. What are the factors that affect the process parameters of in-mold decoration?

The influence of in-mold decoration process parameters is as follows

- Workpiece design

- Selection of sheet material

- Amount of diluent/curing agent

- Drying of ink

- The time between printing and injection molding

- Injection port

- Injection temperature

- Selection of thermoplastic materials

- Thermoplasticity

- Injection pressure

- Cycle cycle

- Machine temperature

19. What are the main points of injection molding?

- The shorter the run, the better. Heat flow is the best.

- The gate area can be increased or multi-point gates can be used.

- Selection of injection materials: the higher the fluidity, the lower the injection temperature, the better

- In the gate position, you can choose to prevent ink staining.

- Try not to choose the highest stretch position of the projectile intersection.

20. In the injection molding of in-mold decoration, what is the reason for the easy separation of the plates?

The reasons why the plates are easily separated during the in-mold decoration injection molding process are as follows:

- There is residual solvent in the ink.

- Improper control of the temperature, pressure, and cooling system of the injection molding machine, and the control is not good.

- The pigment content is too high, or the injection molding process does not match.

- The ink itself has poor binding fastness to the substrate

- The plastic is injected with moisture.