China Insert Injection Molding Manufacturer and Supplier

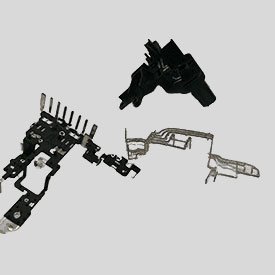

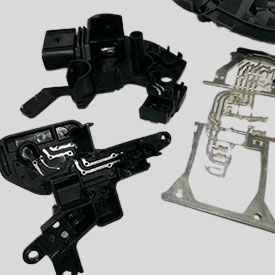

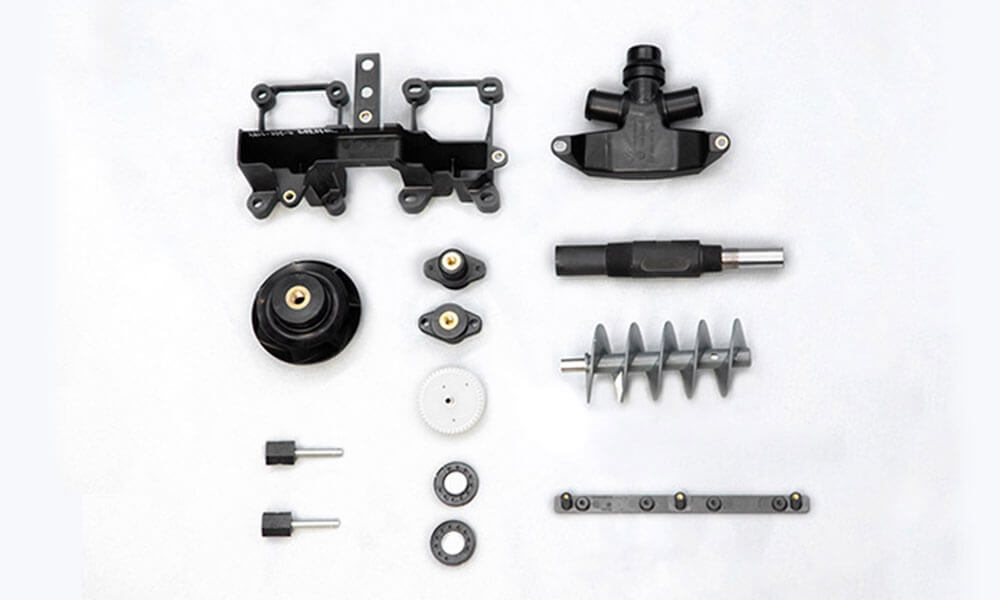

Holly offers high-quality Insert Injection Molding services for a variety of industries, including automotive, electronics, medical, and industrial applications. Our advanced injection molding technology ensures precision and reliability, allowing us to produce parts with intricate designs and tight tolerances.

We work with a wide range of materials, including ABS, POM, PP, PA, and more, and can integrate metal inserts to enhance part strength and functionality. Our team is experienced in handling both small-scale prototypes and large-volume production runs, ensuring efficient and cost-effective solutions.

At Holly, we prioritize customer satisfaction through ISO-certified processes and strict quality control measures. We are committed to providing durable, high-performance parts, delivered on time and within budget. Contact us today to learn how our Insert Injection Molding services can meet your specific needs.

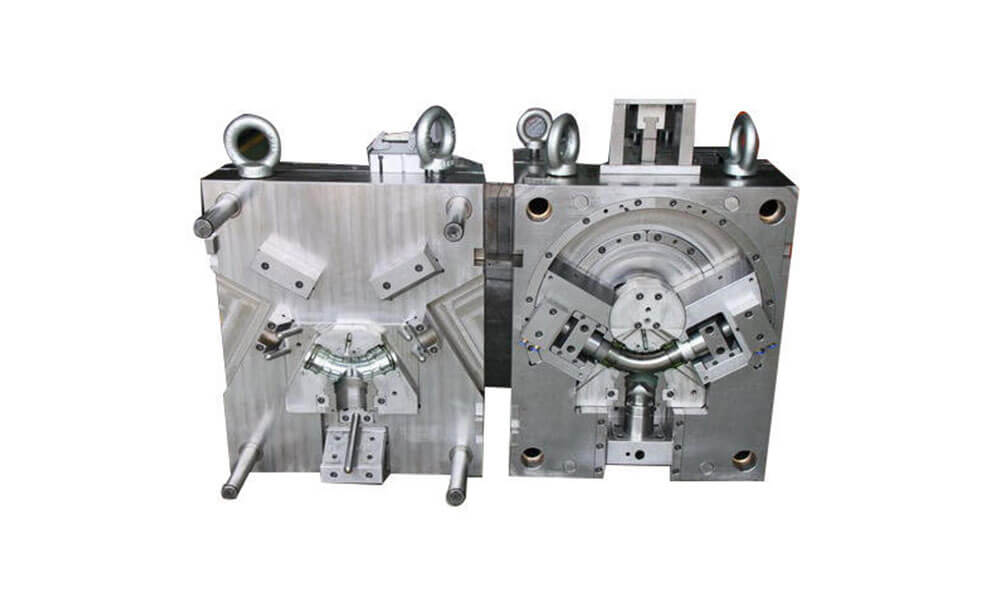

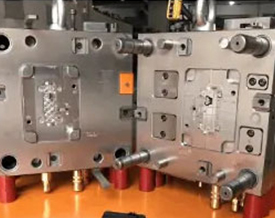

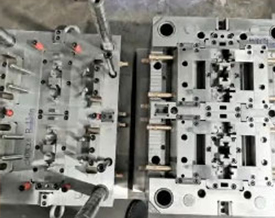

Explore our insert injection molding mold

We specialize in insert molding, providing high strength, lightweight and cost-effective solutions. Our mold categories include single-cavity molds, multi-cavity molds, family molds and custom insert molds. This advanced process is suitable for automotive parts, large structural parts, furniture frames, industrial housings and household appliance housings. By precisely controlling the insertion process, we improve the structural integrity of our products, ensuring high quality and durability to meet the individual needs of our customers.

Insert Injection Molding Capabilities

Material of Insert Injection Molding Available

| ABS

ABS is a versatile and cost-effective thermoplastic widely used in injection molding. Known for its strength, impact resistance, and heat stability, it is ideal for automotive, consumer electronics, and industrial applications. ABS offers excellent mechanical properties, and easy processing, and can be modified with additives for enhanced flame retardancy or UV resistance. It supports various surface finishes, including painting and plating, making it suitable for both functional and aesthetic components.

|

|

| PP

PP (Polypropylene) is an excellent material for Insert Injection Molding due to its low density, chemical resistance, and durability. It provides strong adhesion to metal inserts and is well-suited for high-volume production. PP is commonly used in automotive, medical, and consumer goods industries. For instance, car interior components like door panels and medical device housings often use PP, as it is lightweight, cost-effective, and resistant to wear and chemicals.

|

|

| PA

PA (Polyamide/Nylon) is ideal for Insert Injection Molding due to its excellent mechanical strength, wear resistance, and high-temperature stability. It provides strong bonding with metal inserts and is suitable for demanding applications. PA is widely used in automotive and industrial components. For example, engine parts, gears, and electrical connectors often use PA for its durability, wear resistance, and ability to withstand harsh environments.

|

|

| POM

POM (Polyoxymethylene) is well-suited for Insert Injection Molding due to its high stiffness, low friction, and excellent dimensional stability. It offers strong adhesion with metal inserts and is ideal for precision applications. POM is commonly used in automotive and industrial components. For example, it is used in precision gears, bearings, and mechanical parts that require high wear resistance and low friction, ensuring long-term performance in demanding environments.

|

|

| PBT

PBT (Polybutylene Terephthalate) is ideal for Insert Injection Molding due to its excellent chemical resistance, high heat stability, and low moisture absorption. It provides strong adhesion to metal inserts and is suitable for high-precision applications. PBT is commonly used in automotive and electronics industries. For example, electrical connectors, motor housings, and automotive lighting components are often made from PBT for its durability and resistance to harsh environmental conditions.

|

|

| Stainless Steel

Stainless Steel is highly suitable for Insert Injection Molding due to its superior corrosion resistance, strength, and durability. It provides excellent performance in harsh environments and bonds well with plastic materials. Stainless steel is commonly used in automotive, medical, and industrial applications. For example, it is used in components like automotive fasteners, medical device housings, and machine parts, where both strength and resistance to corrosion are critical.

|

|

| Aluminum Alloys

Aluminum Alloys are an excellent choice for Insert Injection Molding due to their lightweight, high strength, and excellent thermal conductivity. They provide strong adhesion to plastic materials, ensuring high-performance components in various applications. Aluminum alloys are widely used in automotive, electronics, and aerospace industries. For example, they are commonly used for automotive engine parts, electronic enclosures, and structural components where strength and weight reduction are critical.

|

|

| GF

GF (Glass Fiber Reinforced Plastics) are ideal for Insert Injection Molding due to their enhanced strength, rigidity, and resistance to wear. The addition of glass fibers improves the mechanical properties of plastics, making them suitable for high-load and high-performance applications. GF-reinforced plastics are commonly used in automotive, electronics, and industrial sectors. For example, they are used in automotive under-the-hood components, electrical connectors, and structural parts that require high strength and dimensional stability.

|

|

| CF

CF (Carbon Fiber Reinforced Plastics) are perfect for Insert Injection Molding due to their exceptional strength-to-weight ratio, high stiffness, and superior durability. The carbon fibers provide increased strength while maintaining a lightweight profile, making them ideal for high-performance applications. CF composites are commonly used in aerospace, automotive, and sports industries. For example, they are used in automotive structural components, drone frames, and high-end sporting goods, where both strength and low weight are crucial.

|

|

Insert Injection Molding Finishing Options

| Name | Description |

|---|---|

| SPI A1-A3 | Standard surface finish with minimal texture, providing a smooth but basic surface. |

| VDI | High-quality surface finish with various grades (e.g., VDI 3400) to achieve a smooth, glossy surface. |

| EDM Texturing | Electro-discharge machining creates intricate, precise textures for high-end parts. |

| Mirror Polishing | Glossy, mirror-like finish that enhances the aesthetic appearance of the part. |

| Custom Textures | Tailored textures like matte, soft-touch, or brushed finishes to meet specific design requirements. |

| Bead Blasting | Creates a rough, uniform finish using fine beads, ideal for matte or textured surfaces. |

China Insert Injection Molding FAQ

Insert Injection Molding Service FAQ Guide

In the following guide, you will know everything about Insert Injection Molding.

As a professional injection mold manufacturer, we have 24 years of experience. Holly pays 100% enthusiasm to serve you.

Here is a list of frequently asked questions about insert injection molding. You can check any questions you want to know about Insert injection molding.

For example, the benefits of injection molding. General defects of insert injection molding. When designing a customized insert injection system, what should be taken into consideration?

For further communication, please feel free to contact the Wintergreen team.

1. What is insert injection molding?

Insert molding is a molding process in which different materials are prepared and plastic is injected, and the insert is loaded into the mold. In addition, the molten plastic and the insert are perfectly connected and solidified together.

Integrated products can be produced using the insert molding process. It always meets the basic functions of electrical products. Insert molding is suitable for various industries, such as the toy industry, household industry, automobile industry, home appliance industry, etc.

Insert injection molding is a very widely used process. The Holly team is familiar with the technical details of insert molding.

2. What are the advantages of insert injection molding?

The advantages of insert injection molding are as follows:

Insert injection molding can simplify the molding process. For example, the flexible forming on the rubber gasket can save the tedious process of arranging the sealing ring. Generally speaking, if the plastic parts of the product and the embedded parts are processed separately, it will not only increase the processing time of the product but also increase the labor cost of the processing.

In addition, the quality of the final product cannot be guaranteed, and rework production will increase processing costs. Therefore, insert injection molding is a processing technology that can improve processing efficiency, reduce production costs, and reduce scrap rate.

3. What are the advantages of the insert molding process over thermoforming process?

The advantages of insert molding process over thermoforming process are as follows:

Compared with the hot melt molding process, the gap of the insert molding process can be designed to be narrower, the joint between the molten material and the metal molding can be more closely matched, and the composite molding has higher reliability.

Therefore, insert molding is more applied to products that need to be adapted and assembled together. Because the plastic insert molding product is more waterproof and dustproof, the appearance quality is better. The combined product has good commercial value.

4. Are all the inserts of injection molded parts metal parts?

Not all inserts of injection-molded inserts are metal parts. They are not just metal inserts. Wire, plastic, glass, cloth, paper, wood wire electrical parts, copper, iron, steel, aluminum, ceramics, etc. can be used as inserts.

Insert injection molding realizes the function of combining different materials with plastic parts. The insert injection molding process allows product developers to boldly develop new products. Injection molding machines bring consumers a new and unique product experience. Injection molding of inserts broadens the field of product development, promotes the development of the market, and strengthens the confidence of enterprises in production.

5. What are the steps for mobile positioning insert injection molding?

The steps of mobile positioning insert injection molding are as follows:

- Step 1: Put the metal parts into the fixed mold cavity and fix the positioning, ensure that the metal parts are placed in the correct position and direction, so as to reduce the waste rate of the product.

- Step 2: Close the movable mold and the fixed mold, and the movable part supports the metal part. At this time, the movable parts are the key parts, and the quality must be stable to support the metal parts.

- Step 3: Pouring glue. At this time, the injection must be slow to make the surface firm and smooth and make the metal parts injection molded tightly.

- Step 4: Loosen the movable insert and delay the filing of the glue. At this time, be sure to wait until the glue has cooled down firmly before loosening it.

- Step 5: cooling and demolding. At this time, be sure to peel off the adhesive after cooling down firmly.

6. What are the advantages of active positioning injection molding machines over ordinary injection molding machines?

The advantages of active positioning injection molding machine over ordinary injection molding machine are as follows:

Active positioning insert injection molding can prevent metal parts from displacement during the injection molding process. Keep the fixed position when filling the glue. After the filling is finished, it will be cooled and de-molded, and no positioning holes will be left in the plastic part.

The use of an active positioning injection molding machine can not only improve the appearance of the product but also reduce the defect rate of the product. Actively locate the injection mold, leaving no positioning holes on the plastic parts, which improves the waterproof and dustproof functions of the product and simplifies the production process.

7. When designing a customized insert injection system, what should be taken into consideration?

(1) The shrinkage rate is not uniform when the metal insert is formed. The shape and dimensional accuracy of important parts should be subjected to limit tests in advance.

(2) During the molding process of the insert, the metal insert is easy to deform and shift, so full consideration should be given to the mold composition and mold shape design that are easy to retain the metal insert.

(3) Confirm whether the metal blade needs to be preheated and dried.

(4) Another important factor is to consider the mold core material. Generally, the material with lower hardness is inserted into the main mold core to seal the adhesive.

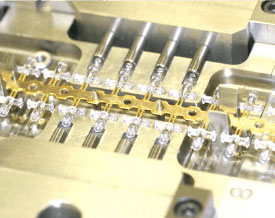

8. When a metal insert serves as an electrical connection point, what are the steps for insert injection molding?

When a metal insert is used as an electrical connection point, the injection molding steps of the insert are as follows:

When the metal insert serves as an electrical connector, its positioning accuracy is required to be higher. In the injection molding process of plastic inserts, a secondary injection molding process is generally used.

The first injection molding is mainly to support and fix the metal wire. When the first injection molding work, the metal wire should be well supported and fixed. The second time is to shape the entire product. When the secondary injection molding is working, attention should be paid to the cooling and demolding of the finished product.

9. What are the main features of metal insert injection molding technology?

(1) Before clamping, make sure that the metal insert is stable in the cavity. If the metal insert floats or falls off, it will cause the final molded part to not be used normally, and even cause damage to the mold. Therefore, various positioning devices are required to ensure the accurate positioning of the metal blade, which increases the complexity of the mold structure. In addition, higher requirements are put forward for the dimensional accuracy of the positioning device arranged in the cooling water channel.

(2) The material selection requirements for metal inserts are very high. The choice of material should not only consider the formability of the metal blade. In the injection process, the impact and corrosion of the high-speed and high-pressure plastic melt on the metal blade should also be considered. In addition, the thickness of the metal blade is also an important factor affecting injection molding.

As the thickness of the metal blade increases, its rigidity increases, and its resistance to plastic melt shrinkage deformation increases. As the thickness increases, the bonding strength of the plastic melt and the metal will be affected. At present, the most commonly used metal inserts are copper, copper, aluminum, aluminum, stainless steel and so on.

(3) The selection of plastic materials should consider the working conditions of the final molded plastic.

Plastic parts with metal inserts have been widely used in the field of electronic automobiles, and higher requirements are put forward for the strength and heat resistance of plastic parts materials. At present, PBT+GF, PEEK, PC, ABS and other plastic materials are widely used.

4) The quality of molded parts is difficult to guarantee. The cooling rate and linear thermal expansion coefficient of metal inserts are different from those of plastics. Molded plastics are likely to form weld marks during the injection molding process. What will aggravate the cracking and warping deformation of the molded plastic during the cooling process, and affect the pass rate of the final molded plastic

10. What are the general defects of metal insert injection molding?

The general defects of metal insert injection molding are as follows.

(1) The bonding strength between the metal insert and the plastic part is low, which may be caused by the fact that the metal insert does not heat up.

(2) The processed parts are prone to warpage and deformation.

(3) The metal insert is easily damaged. Therefore, in the first step of insert injection molding, the metal parts are placed in a fixed mold cavity and fixed in position. The metal parts must be placed carefully.

(4) The dimensional accuracy is difficult to control.

(5) Finished parts are prone to water trapping.

11. What is the difference between insert molding and over-molding?

The difference between insert molding and over-molding is as follows:

Molds that overmold products wrap the product, allow it to naturally cool and inject it into another mold for wrapping. The insert mold is a mold that puts the insert directly into the mold at the beginning of the molding process.

Overmolding requires two or more injections. The insert molding only needs one-time injection molding. Compared with overmolding, insert molding simplifies the production process and shortens the injection cycle.

12. What industries are inserted molding mainly used for?

The main application industries for insert molding are:

Insert molding is suitable for industries such as toys, household appliances, automobiles, and home appliances. It is a very common process to use insert molding.

The Holly team is familiar with the technical details of insert molding. Insert molding is a molding process in which different materials are prepared and plastic is injected, and the insert is loaded into the mold. In addition, the molten plastic and the insert are perfectly connected and solidified together. Integrated products can be produced using the insert molding process.

13. Why is the insert molding process used for complex metal and plastic integrated products?

Since the formability and bendability of plastic materials complement the rigidity, strength, and heat resistance of metals, the insert molding process can be firmly made into complex metal-plastic integrated products.

Insert injection molding is a very widely used process. The Holly team has been familiar with the technical details of Insert Molding for 24 years. Insert molding is a molding process in which different materials are prepared and plastic is injected, and the insert is loaded into the mold. In addition, the molten plastic and the insert are perfectly connected and solidified together. Insert molding process can be used for the production of integrated products

14. Why is the insert molding process generally used in the production of electrical products?

Because the insert molding process uses the insulation of plastic materials and the conductivity of metals, the properties of the two materials are perfectly combined.

The finished product can meet the basic functions of electrical products: conductivity and insulation. Insert injection molding is a very widely used process. The Holly team is familiar with the technical details of insert molding.

Insert molding is a molding process in which different materials are prepared and plastic is injected, and the insert is loaded into the mold. In addition, the molten plastic and the insert are perfectly connected and solidified together. Integrated products can be produced using the insert molding process.

15. For products that are easily damaged, such as glass, coils, electrical parts, etc., what factors should be considered before designing the insert mold?

For products that are easily damaged, the factors that we need to consider are as follows:

Before mold design, for products that are easily damaged, such as glass, coils, and electrical parts, it is necessary to consider the selection of appropriate resin and molding conditions. We need to take into account the number of insert molding, as well as the fusion of plastic and glass, coils, and electrical components.

Glass, coils, and electrical parts are difficult to repair. We need to reserve some space in the mold for insertion. Finally, it is necessary to consider the appropriate mold size tolerance and mold temperature, as well as the design of the gate cross-sectional area.

16. What should we do if we want to completely seal the insert in the plastic material?

If we want to completely seal insert the plastic material. In the early stage of mold design, it is necessary to fully consider the structure of the mold design and select the appropriate mold structure. Besides, the number of mold inserts must also be considered.

In addition, we must also consider choosing the right mold size and tolerance, choosing the right plastic shrinkage, choosing the right plastic, and choosing the right product wall thickness. Sometimes it is necessary to preheat the insert part and around the glue insert two or more times.

17. How to realize automatic production of insert molding?

If you want to achieve automated production, you need to combine the vertical injection molding machine with the robot assembly. Both the insert molding machine and the assembly must meet certain accuracy requirements.

When the insert molding is automated, the production cycle is greatly shortened, the production efficiency is improved, the processing cost is reduced, and the molding failure rate is reduced.

18. Why do metal inserts need to be positioned during molding?

If the metal inserts are not positioned during molding, or the metal inserts are unstable when pouring, the metal parts will shift.

19. Why is insert molding widely used in the production of automotive plastic products?

Injecting metal inserts into plastics blends metal and plastics advantages. On the one hand, metal blades can effectively improve the local mechanical strength and wear resistance of the product. The formed parts are used as structural load-bearing parts of automobile bodies, etc.

It not only meets the requirements of mechanical performance but also conforms to the development trend of automobile lightweight. On the other hand, combining the good electrical conductivity of metal inserts with the good insulating properties of plastics enables the finished part to be used in electronic circuits and other aspects.

20. In the molding of plastic inserts, how to improve the bonding strength between metal inserts and plastic inserts?

Reduce the influence of the external environment on the bonding strength of the metal blade and the plastic melt. Pay attention to the control of mold temperature and humidity in the production environment. Consider whether the metal blade needs to be heated.

21. How should insert injection molding be considered?

(1) Insert mold design: Good insert mold design and structure are the keys to the smooth production of inserts and parts. Careful thinking and consideration are required in the early stage to avoid problems in the later stage.

(2) Sufficient material: No matter which material you use, there must be enough material to support the insert, because thin walls will cause the insert to fall off the rest. It is necessary to ensure that there is enough plastic material to place the insert correctly.

(3) Insert pressure: This is a very important factor. Inserts need to withstand pressure because the molding process will produce a lot of pressure. It is vital to ensure that the inserts can withstand pressure without cracking or deforming.

(4) Insertion temperature: The insert must be safely exposed to the required temperature to melt the injection material without deforming the insert. If the insert cannot withstand the temperature required by the molten plastic material. In order to use it safely, it needs to find a plastic material with a higher melting point.

22. Why choose Holly to produce insert injection molds?

(1) Holly has conducted research on the defects of insert injection molding for many years and has solved the problem of weak adhesion between metal inserts and plastic parts during insert injection molding.

(2) Holly has been producing automotive products that require insert molding technology for many years, such as automotive products with metal inserts such as automotive electronic instrument panels.

(3) The Holly team has a wealth of experience in injection molding inserts for embedded parts, and can respond to customer questions within 24 hours.

(4) If necessary, Holly Team can fly to your city to solve problems on the spot.

23. Design Features and Benefits

The ceramic lagging has a longer service life due to its durability and reduced lagging wear. The amount of ceramic coverage on the surface of the lagging can be customized according to the application. Besides, you can also increase or decrease the level of friction and grip for the amount of ceramic cover.

Dimple Profile for Reduced Belt Slippage

The ceramic tiles on the ceramic lagging adopt a pit-shaped design, which greatly reduces the slippage between the belt and the transmission wheel. The reduction in sliding is due to the rough ceramic surface, which produces a coefficient of friction that is twice that of the rubber coating.

Since the pit shape reduces belt slippage, ceramic lagging is especially suitable for wet or muddy conditions. Slippage is a bigger problem. In addition, the dimple ceramic lagging reduces belt slippage and can increase the life of the conveyor belt, because consistent belt slippage will cause belt wear, regardless of the lagging type.

Wear Resistant

Beltcare ceramic lagging has the general advantages of the ceramic pulley, that is, it improves the wear resistance. The wear-resistant design of the ceramic lagging means that it will last longer in harsh conditions before it needs to be replaced.

Embossed Rubber Lagging Design

One of the unique design features of the Beltcare ceramic lagging is the “arrow-boss” design, which is an embossed rubber lagging design. This design feature achieves the greatest drainage benefit, which is superior to traditional rubber pulley lagging in this respect.

On-Site Bonding

In addition to reducing belt slippage, improving water shedding and abrasion resistance, Beltcare ceramic coating is polished or an optional bonding layer is available to enable it to be cold bonded on site.

24. Conclusion

Ceramic Pulley Lagging is a premium lagging where the ceramic tiles are molded into a rubber compound. This makes for excellent traction, eliminates slippage, and offers excellent abrasion resistance. Ceramic Pulley Lagging is especially suited for pulleys with slippage and excessive wear & tear problems which make normal rubber lagging ineffective. It is widely used in drive pulleys and can also be used on snub, bend, and tail pulleys.

Beltcare uses model 95 ceramic tiles, so the lagging abrasion resistance can extend more, it ensures existing or new pulleys’ long life. Thus reducing cost. As the ceramic cover area decides lagging slip resistance, Our general ceramic coverage reaches 40%. It provides higher belt traction & stops belt slippage even under wet & muddy conditions. And for special purposes, ceramic tiles coverage of 59%, 100%, 15% are also available

We choose excellent tile bonding chemistry to eliminate ceramic tiles loss and also use the premium rubber compound to ensure ceramic tiles have maximum flexibility and support. The design provides more grip than other ceramic pulley lagging. Customized ceramic lagging strips are also provided on varying pulley diameters to reduce waste and installation time.