Gas Assist Injection Molding Service

Holly specializes in Gas Assist Injection Molding, an advanced technology that reduces material usage and enhances part strength. This process uses gas to create hollow sections inside plastic parts, allowing for lighter and more durable components. Whether you’re in the automotive, electronics, or consumer goods industry, we provide efficient solutions to meet your specific design requirements.

We utilize state-of-the-art equipment and materials, ensuring precision and consistency throughout the molding process. Our experienced team is skilled in creating complex, high-quality molded parts with smooth surfaces and intricate details. From prototypes to high-volume production, we deliver fast turnaround times and cost-effective solutions without compromising on quality.

At Holly, our commitment to excellence is backed by strict quality control and adherence to global standards, including ISO certifications. With our Gas Assist Injection Molding service, you can expect superior durability, reduced cycle times, and optimized production costs. Whether you need small-batch runs or large-scale manufacturing, we offer tailored services to suit your needs. Contact us today to discuss how Holly can bring your injection molding projects to life!

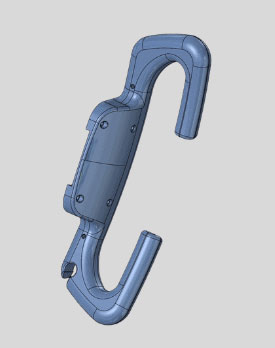

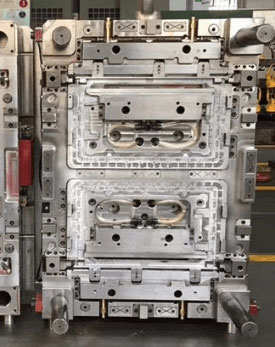

Explore our Gas Assist Injection Mold

We specialize in gas-assisted injection molding, providing high strength, lightweight and cost-effective solutions. Our mold categories include single-cavity molds, multi-cavity molds, family molds and custom airway design molds. The gas-assisted injection molding process is suitable for automotive parts, large structural parts, furniture frames, industrial housings and home appliance housings. By controlling gas injection, we reduce material use, reduce distortion, and enhance structural integrity to ensure high quality and durable products that meet our customers ‘individual needs.

Gas Assist Injection Molding Capabilities

Gas Assist Injection Molding Material Available

| PP

PP is ideal for Gas Assist Injection Molding due to its excellent flowability, low density, and good chemical resistance. It is lightweight, making it perfect for producing hollow, strong, and durable parts. In automotive applications, PP is commonly used for components like bumpers, door panels, and interior parts. Its ability to form complex shapes with minimal material usage is a key benefit in this process.

|

|

| PC

PC is highly suitable for Gas Assist Injection Molding due to its high strength, impact resistance, and transparency. The gas-assisted process helps reduce material usage while maintaining excellent structural integrity. PC is commonly used in automotive applications like headlamp lenses and exterior lighting covers, where high impact resistance and optical clarity are essential. It’s also used for durable electronic housings and medical components, offering superior toughness and heat resistance.

|

|

| PU

PU is an ideal material for Gas Assist Injection Molding due to its excellent flexibility, abrasion resistance, and high resilience. The gas-assisted process enables the creation of lightweight yet durable components with complex geometries. PU is widely used in automotive parts like bumpers, seals, and gaskets, where flexibility and impact resistance are key. It’s also used for cushioning in consumer goods and medical devices, providing high elasticity and long-lasting performance.

|

|

| PA

PA (Nylon) is ideal for Gas Assist Injection Molding due to its high strength, wear resistance, and excellent dimensional stability. The gas-assisted process helps reduce material usage while maintaining part strength and functionality. PA is widely used in automotive parts like engine covers, gears, and bearings, where high mechanical strength and wear resistance are required. It’s also commonly used in industrial components, providing durability and long service life under stress.

|

|

| PS

PS is a cost-effective material suitable for Gas Assist Injection Molding due to its good flowability and ease of molding complex shapes. The gas-assisted process allows for lightweight yet strong components with smooth surfaces. PS is commonly used in consumer electronics housings, packaging, and household products, where ease of processing and smooth finishes are crucial. Its excellent clarity also makes it ideal for transparent applications.

|

|

| ABS

ABS is a highly versatile material, perfect for Gas Assist Injection Molding due to its excellent mechanical properties, impact resistance, and ease of processing. The gas-assisted process reduces material use while ensuring high strength and lightweight parts. ABS is commonly used in automotive interior components, electronics housings, and consumer goods. Its ability to hold intricate designs and support various surface finishes makes it ideal for both functional and aesthetic applications.

|

|

Gas Assist Injection Molding Finishing Options

| Name | Description |

|---|---|

| Mirror Polishing | Provides a high-gloss surface finish, ideal for products requiring high aesthetics. |

| Sandblasting | Uses fine particles to create a rough texture, increasing friction and durability. |

| Plating | Enhances surface hardness and appearance through chrome, nickel, or other coatings. |

| Texturing | Adds varied surface patterns for aesthetics and durability. Ideal for automotive and consumer products. |

| Painting | Applies a protective and decorative layer of paint, adding color and gloss. |

| EDM Texturing | Uses electrical discharge to create precise and uniform surface textures. |

China Gas Assist Injection Molding Manufacturer FAQ

Gas Assist Injection Molding FAQ Guide

In the following guide, you will know everything about Gas Assist Injection Molding.

As a professional gas-assisted injection molding manufacturer with 20+ years of experience, Holly has paid 100% enthusiasm for you. Here is a list of frequently asked questions for gas-assisted injection molding, you can check any questions about gas-assisted injection molding.

Here is what you need to know, such as:

- What are the advantages of gas-assisted injection molding?

- What are the disadvantages of gas-assisted injection molding?

- What is the difference between gas-assisted injection molding mold and traditional mold?

For further communication, please feel free to contact the Holly team.

1. How does gas-assisted injection molding work?

The gas-assisted injection molding workflow is as follows:

When gas-assisted injection molding work, the measured melt is first injected into the cavity, and then gas (usually nitrogen) is injected into the melt through a special nozzle, and the gas diffuses to push the melt into the cavity.

After that, for the pressure-holding filler, the pressure of the gas in the melt is kept constant or increased to a certain extent. After cooling, the plastic part can be demolded by removing the gas from the plastic part.

2. What are the steps in the gas-assisted injection molding process?

The gas-assisted injection molding process steps are as follows:

- The first stage of gas-assisted injection molding: plastic injection, the melt enters the cavity, and the cold wall forms a thin solidified layer.

- The second stage of gas-assisted injection: the gas is incident, the inert gas enters the molten plastic, and the centre of the unsolidified plastic is pushed into the cavity.

- The third stage of gas-assisted plastic injection molding: At the end of the gas event, the gas continues to push the plastic to melt until the cavity is filled.

- The fourth stage of gas-assisted injection molding: gas pressure holding. In the pressure holding state, the gas in the gas path compresses the melt filling material to ensure the appearance of the part.

3. What are the components of the gas-assisted injection molding system?

The composition of the gas-assisted injection molding system is as follows:

- Ordinary injection molding machine (the material calculation accuracy is generally higher).

- A nitrogen control system, including self-enclosed gas auxiliary nozzle.

- High-pressure nitrogen generator.

- Industrial nitrogen cylinders and air compressors that provide boosting power.

- A gas-assisted injection molding mold is designed.

- Auxiliary nozzle

4. What are the injection methods for gas-assisted injection molding?

The injection methods available for gas-assisted injection molding are as follows.

1) Seal gas injection

Inject gas directly into the mold cavity to make the finished plastic hollow. No need to use live valves, just through simple mold processing. Install the gas-assisted nozzle on the mold. There may be one or more places to inject gas on the same mold

2) Natural gas nozzle

A dedicated closed air injection nozzle can be installed on the injection machine.

5. What are the advantages of gas-assisted injection molding?

The advantages of gas-assisted injection molding are as follows:

1) Freedom of design.

- Plastic parts with complex functions can be integrated into a single component.

- Thick-walled parts and thin-walled parts can be combined on the same piece.

- The strength of the product can be increased by using hollow “reinforcing rib” sections.

- Improve the quality of parts.

- By reducing micro-shrinkage, the deformation and deformation of the product are reduced.

- Eliminate sink marks.

- As the number of injection points decreases, so does the corrugation and weld lines.

2) Reduce production costs.

- As the wall thickness is reduced, the total weight of the finished part is also reduced.

- Due to the smaller wall thickness, the cooling time and cycle time are shortened.

- As the clamping force and injection pressure are reduced, energy consumption costs are reduced.

- Due to the integration of parts, assembly costs are reduced.

3) Reduce investment costs.

- Due to the low injection pressure, the clamping pressure of the injection molding machine can be reduced, and the injection molding machine with a smaller tonnage can be used.

- Due to the low injection pressure, the manufacturing cost of the mold is reduced.

- The injection pressure is low, which reduces the loss of the mold, thereby reducing the maintenance cost.

6. Compared with traditional injection molding methods, what are the advantages of gas-assisted injection molding?

The advantages of gas-assisted injection molding are as follows.

- It can produce three-dimensional hollow plastic parts with uneven wall thickness and complex shapes.

- When the gas forms a continuous flow path from the gate to the flow end, there is no pressure loss. So as to realize low-pressure injection molding. At the same time, plastic parts with residual stress have small warpage and stable dimensions.

- With the help of airflow, the forming performance of plastic parts is improved. Therefore, gas-assisted injection is of great help to the formation of thin-walled plastic parts and to reduce the weight of plastic parts.

- Due to the low injection pressure, parts can be produced on the injection molding machine with a smaller clamping force.

7. What are the disadvantages of gas-assisted injection molding?

The disadvantages of gas-assisted injection molding are as follows.

- It is necessary to add an air supply device and a filling nozzle, which increases the equipment cost.

- A gas-assisted injection molding machine needs to be precise as well as controllable.

- The surface of injected gas and non-injected gas produces different glosses.

8. What is the basis of gas-assisted injection molding?

The basic principles of gas-assisted injection molding are as follows:

- At the entry point, when the pressure of the gas is greater than the pressure of the plastic, the gas is injected into the plastic.

- The gas injected into the plastic must be prevented from escaping from the point of entry.

- The gas in the plastic will flow from high pressure to low pressure.

- When the plastic is cooled and molded, the pressure is controlled by gas, not the molding machine.

- In a continuous air channel, the pressure of the gas at the inlet and the end is the same.

- In order to apply uniform pressure throughout the mold, high-pressure gas will flow through very small holes very quickly.

- The gas in the plastic must be discharged before the mold is opened, or discharged to the atmosphere through drainage, or returned to the original source through a filter for recovery.

- Compared with gas, plastic is incompressible. Therefore, increasing the gas pressure cannot achieve the filling effect.

- The shrinkage of the plastic during the cooling process can be compensated by the expansion of the gas.

9. What should I pay attention to when gas-assisted injection molding?

The matters needing attention during gas-assisted injection molding are as follows:

- The flow of gas and plastic should be the same.

- If there is no blocking valve in the nozzle of the injection molding machine, the time for filling the filling tube (the screw moves backwards) should be extended as much as possible to prevent the high-pressure plastic and gas in the mold from flowing back into the material tube.

- After the injection molding machine ejects the plastic, the pressure is required for the air supply during the molding and cooling process of the plastic.

- The gas enters the middle of the thicker section along the path of least resistance. Therefore, this part of the plastic is still in a molten state and has the lowest viscosity. In addition, gas flows from high pressure to low pressure or from low temperature to high temperature.

- At the gas entry point, the gas injection pressure is greater than the plastic injection pressure, and the gas will be set into the plastic.

- If the gas leaks, effective pressure cannot be provided. In addition, the use and cost of natural gas will increase.

10. What are the defects of gas-assisted injection molding?

The defects of gas-assisted injection molding are as follows:

- Blowing wear.

- The gas failed to reach the end of the airway.

- Poor cavity exhaust (poor runner).

- Streamlines appear at the end of product molding.

- Hesitation.

- Depression.

- When the mold is opened, the product expands because the gas pressure is not released.

- The surface of the product is sunken or poorly collapsed.

11. In gas-assisted injection molding, how to avoid gas blowing through the product?

If you want to avoid gas blowing through the product, you must pay attention to:

- The gas injection time is delayed (let more plastic enter the mold first).

- Reduce the rate of gas pressure rise.

- Reduce the high pressure holding time.

- Increase the injection volume.

- Reduce the pressure of the first high-pressure holding (HP1).

- Replace materials.

- The crystalline material is better.

12. In gas-assisted injection molding, what should I do if the gas cannot reach the end of the airway?

When the gas fails to reach the end of the airway, pay attention to:

- Reduce plastic emissions.

- Early natural gas injection time.

- Increase the rate of gas pressure rise.

13. In gas-assisted injection molding, what should I do if the cavity is not well vented (bad runner)?

When the cavity is poorly vented (poor streamline), pay attention to:

- Reduce the injection speed of plastic

- Modify the injection point (filling point) of the plastic,

- Increase the injection port

14 In gas-assisted injection molding, what should we do when there is a streamline at the end of the molding process?

When the streamline appears at the end of the shape, we should pay attention to:

- The gas injection time is early.

- Increase the rate of gas pressure rise.

15. How to avoid hysteresis marks in gas-assisted injection molding?

If we want to avoid the traces of hysteresis in gas-assisted injection molding, we should:

- The gas injection time is early.

- Reduce the injection pressure and injection rate of the plastic, so that the gas can easily enter the plastic.

- Change the gas inlet position to a “low-pressure plastic zone”, such as downstream of the plastic inlet point; or increase the cross-section of the plastic inlet point

Note: the plastic will continuously flow until both plastic and gas are filled in the cavity.

16. How to deal with depressions in gas-assisted injection molding?

- Increase the high-pressure reserve.

- Early natural gas injection time.

- Increase the pressure of HP1.

- Increase the airway on the concave surface.

17. In gas-assisted injection molding, when the mold is opened, what should I do if the product expands without gas pressure leakage?

- Reduce the total time of gas injection.

- Reduce low pressure holding time and lower ejection pressure.

- Blow off the plastic at the entrance.

- Change the point where the gas enters.

18. When the surface of an injection-molded product collapses, what should we do?

- Add cooling water to lower the mold temperature

- Reduce the firing rate of plastics

- Increase gas pressure

- Check for leaks

- Replace plastic

19. How to reduce mold costs when designing gas-assisted injection molds?

When designing gas-assisted injection molds, we can reduce costs as follows:

- Reduce product wall thickness, reduce product weight, reduce production operations, and reduce costs.

- Use high flow index MFI materials or increase the firing rate of plastics, thereby reducing the product wall thickness.

- Use low-cost or low-density plastics to increase flow.

20. How to reduce the molding time when using gas-assisted injection molding?

When using gas-assisted injection molding, we can reduce the molding time as follows:

- Reduce the wall thickness of the product and reduce the cooling time.

- Lowering the mold temperature can reduce the cooling time.

- Mold materials with good thermal conductivity, such as aluminium or copper.

- Cool with water after forming.

21. In gas-assisted injection molding, what happens when gas enters the plastic in the direction of least resistance?

- Thick parts.

- The part with the lowest plastic viscosity.

22. What can Moldflow do when gas-assisted molding technology is applied to car door handles?

The Moldflow gas-assisted molding technology is used to optimize the design and process parameters such as air intake position, air intake time, injection volume, delay time, and gas pressure retention curve.

Reduce the blindness of the design process, reduce the number of mold trials and mold changes, and reduce the trial time.

Save costs and shorten the product development cycle.

23. What are the characteristics of gas-assisted injection molds?

1) Too large or too small is not conducive to the penetration of the end of the airway. There should be a large arc transition at the bend of the airway. Air flow channels can be provided at the roots of structures such as stiffeners and self-tapping screws. Use this structure as part of the airway filling and contraction.

2) The air-needle fit gap should be less than 0.02mm to prevent molten materials from entering the air-needle gap.

3) The sealing around the air needle and the mold must be good.

4) The gas needle is designed to prevent nitrogen from escaping from the gap between the gas needle and the product during the cooling process.

5) The air needle should not be too close to the gate. Due to the highest temperature near the gate during filling and the lower viscosity, it is easy for the molten material to enter the air needle gap and cause shrinkage, blow-cracking and other defects.

24. Which products are generally used for gas-assisted injection molding?

Products made from plastic can be molded using gas-assisted injection molding.

Tubular and rod-shaped parts such as door handles, swivel seats, hooks, armrests, railings, hangers.

Large flat parts, such as door panels, copier shells, dashboards, etc.

Bumpers, for example, are complex parts with uneven thickness and shapes.

Defects such as sink marks and stains are caused by the shells of home appliances, car bodies, and traditional injection molding processes.

25. What is the difference between gas-assisted injection molding mold and traditional mold?

Compared with traditional molds, gas-assisted molds have air intake elements (air needles) and air intake design. The term “airway” can be simply understood as a gas channel. The gas needle is the key component of the gas-assisted tool. It directly affects the stability of the process and product quality.

26. Can you give a brief explanation of gas-assisted injection molding parts and gas-assisted injection molding molds?

1) First consider which wall thickness needs to be hollowed out and which surface indentations need to be removed, and then consider how to connect these areas to become airways.

2) Large structural part: the airway becomes thinner as a whole, and locally thickened.

3) The airway should be evenly distributed in the cavity according to the main flow direction to avoid a closed airway.

4) The cross-section of the airway should be close to a circle so that the gas flow is smooth, and the cross-sectional size of the airway should be appropriate. An air passage that is too small can cause gas penetration, and an air passage that is too large can cause welds or cavitation.

5) The airway should extend to the final filling area (usually on a non-obvious surface), but does not need to extend to the edge of the cavity.

6) The main airway should be as simple as possible, the length of the branching airway should be the same, and the end of the branching airway can be gradually reduced to prevent the gas from accelerating.

7) If the airway is straight, it should not be bent (the fewer bends, the better).

The airway corner should use a larger fillet radius.

8) For multi-cavity molds, each cavity has an independent air nozzle supply.

9) The gas should be confined in the airway and penetrate to the end of the airway.

10) The exact cavity size is very important.

11) The balanced cooling of the parts is very important. When the gate is used for air intake, flow balance is very important for uniform gas penetration.

12) Accurate injection volume is very important, the error of each injection volume cannot exceed 0.5%.

13) The overflow well during the final filling promotes gas penetration, increases the cavitation rate of the gas path, eliminates the traces of hysteresis, and stabilizes the product quality. A valve is set between the mold cavity and the overflow well to ensure that the final filling occurs in the overflow well.

14) The small gate prevents the gas from flowing back into the flow channel when the air nozzle is inhaled.

15) The intake valve can be placed on a thin wall and kept a distance of at least 30mm from the intake port to avoid gas permeation and backflow.

16) The air nozzle should be placed on a thicker wall and away from the final filling.

17) The outlet direction of the air duct is consistent with the flow direction of the material.

18) Keep the front edge of the melt flow at a constant speed to avoid the formation of a v-shaped front edge of the melt flow.

19) In the absence of material injection, the volume of the cavity in front of the air inlet shall not exceed half of the total volume of the airway.

- 1. How does gas-assisted injection molding work?

- 2. What are the steps in the gas-assisted injection molding process?

- 3. What are the components of the gas-assisted injection molding system?

- 4. What are the injection methods for gas-assisted injection molding?

- 5. What are the advantages of gas-assisted injection molding?

- 6. Compared with traditional injection molding methods, what are the advantages of gas-assisted injection molding?

- 7. What are the disadvantages of gas-assisted injection molding?

- 8. What is the basis of gas-assisted injection molding?

- 9. What should I pay attention to when gas-assisted injection molding?

- 10. What are the defects of gas-assisted injection molding?

- 11. In gas-assisted injection molding, how to avoid gas blowing through the product?

- 12. In gas-assisted injection molding, what should I do if the gas cannot reach the end of the airway?

- 13. In gas-assisted injection molding, what should I do if the cavity is not well vented (bad runner)?

- 14 In gas-assisted injection molding, what should we do when there is a streamline at the end of the molding process?

- 16. How to deal with depressions in gas-assisted injection molding?

- 17. In gas-assisted injection molding, when the mold is opened, what should I do if the product expands without gas pressure leakage?

- 18. When the surface of an injection-molded product collapses, what should we do?

- 19. How to reduce mold costs when designing gas-assisted injection molds?

- 20. How to reduce the molding time when using gas-assisted injection molding?

- 21. In gas-assisted injection molding, what happens when gas enters the plastic in the direction of least resistance?

- 22. What can Moldflow do when gas-assisted molding technology is applied to car door handles?

- 23. What are the characteristics of gas-assisted injection molds?

- 24. Which products are generally used for gas-assisted injection molding?

- 25. What is the difference between gas-assisted injection molding mold and traditional mold?

- 26. Can you give a brief explanation of gas-assisted injection molding parts and gas-assisted injection molding molds?