Custom OEM & ODM Medical Plastic Injection Molding Solutions

Holly offers high-precision medical plastic injection molding services, catering to the unique needs of the healthcare industry. With over 20 years of expertise in plastic molding, we provide custom OEM and ODM solutions for medical devices, ensuring compliance with stringent global standards such as ISO 13485. Our state-of-the-art injection molding equipment and advanced technologies guarantee precision, durability, and high-quality production of complex medical components, from small batch runs to large-volume production.

We specialize in a wide range of medical-grade materials, including biocompatible plastics, ensuring safety and reliability in every product. Our experienced engineering team works closely with clients to deliver tailored solutions that meet exact specifications and performance requirements. Whether you need surgical tools, drug delivery systems, or diagnostic device components, Holly provides cost-effective, timely, and precise manufacturing.

With an extensive production capacity and strict quality control measures, we ensure that each part meets rigorous performance standards, making us a trusted partner for medical plastic injection molding. Contact us today for expert solutions tailored to your medical molding needs!

Explore Our Medical Plastic Injection Molding Capacities:

Holly specializes in medical plastic injection molding, offering a variety of products for the healthcare industry. Our product categories include surgical instruments, diagnostic device components, drug delivery systems, medical housings, and custom medical parts. We ensure precision and reliability by using high-quality, biocompatible materials to meet stringent industry standards. From simple components to complex, micro-molded parts, Holly delivers tailored, cost-effective solutions with exceptional quality and performance.

Featured Medical Components We Produced

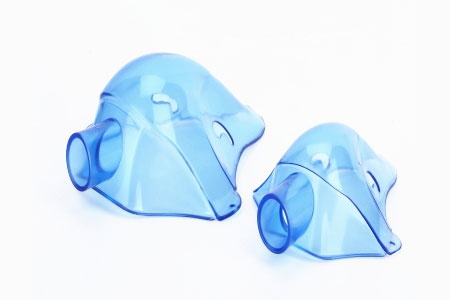

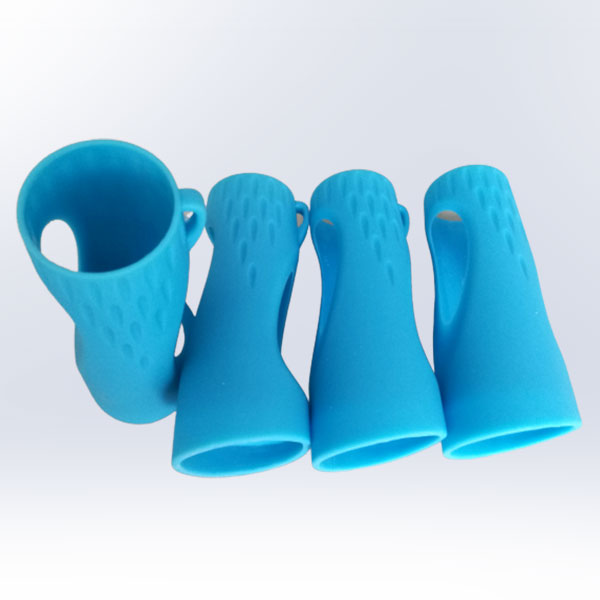

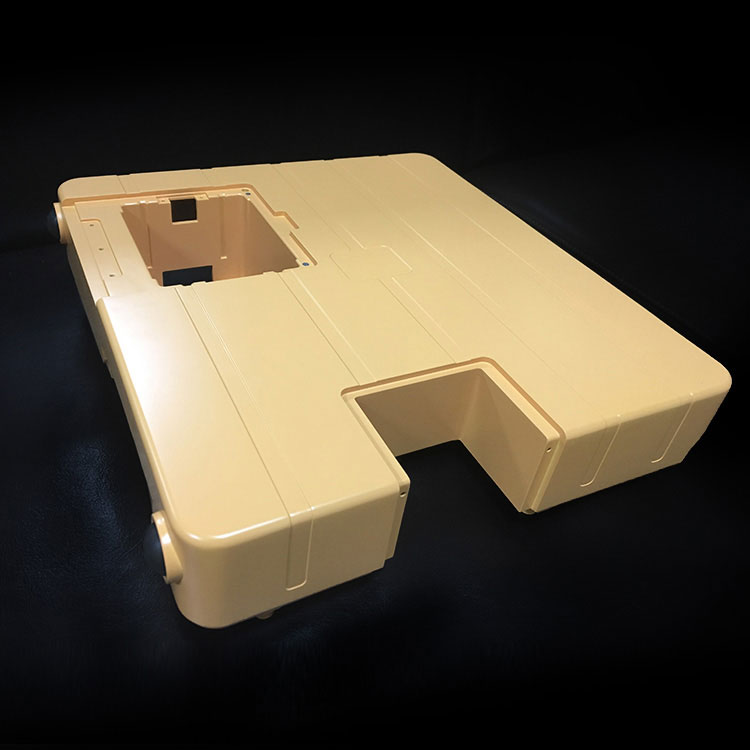

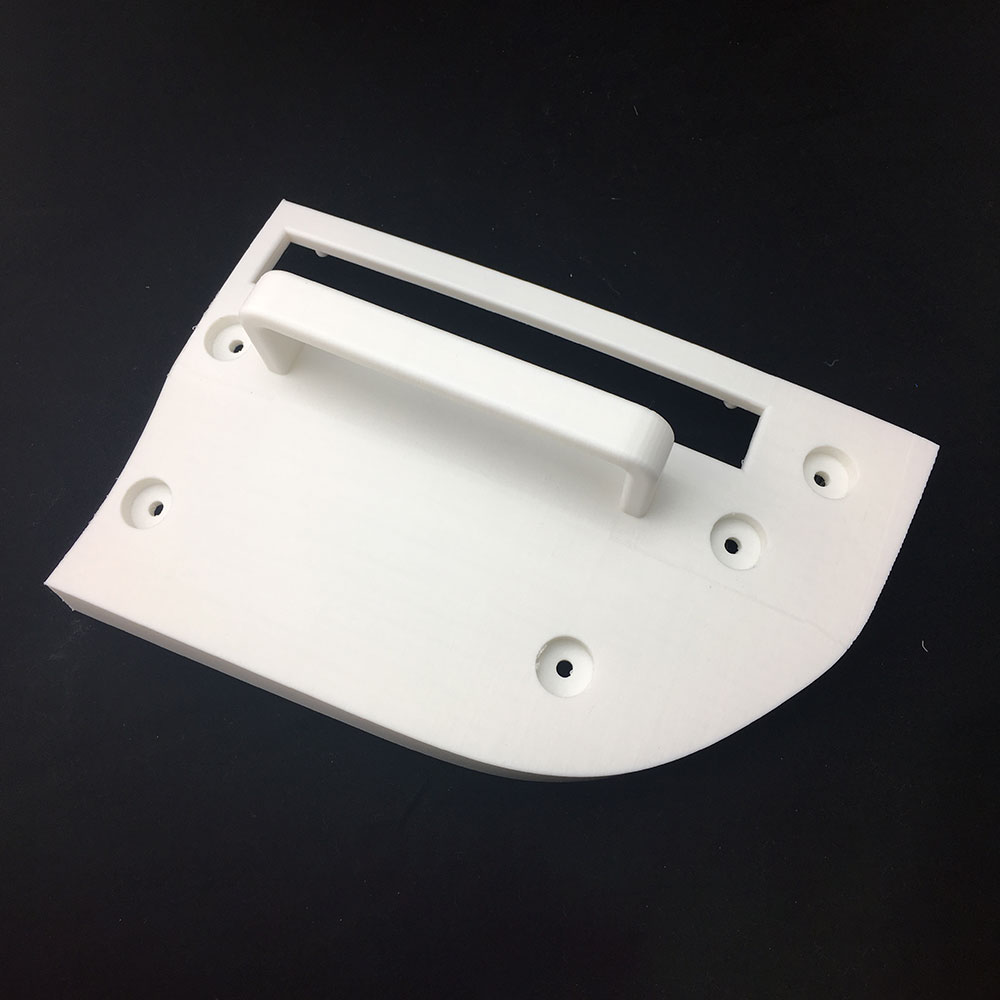

Holly specializes in medical plastic injection molding, providing high-precision solutions for a wide range of medical applications. Our product categories include surgical instruments, diagnostic device components, drug delivery systems, medical housings, and custom medical parts. Specific products include syringe components, inhaler housings, blood glucose meters, surgical handles, and diagnostic test kits. We use advanced molding technology and high-quality materials like PEEK, Ultem®, and TPEs, ensuring reliability, durability, and biocompatibility for every part.

Medical Plastic Injection Molding Capabilities

Explore Our Latest Medical Plastic Injection Molding Products

Discover our latest medical plastic injection molding components, crafted with precision by our experienced engineering team. From prototypes to large-scale production, our parts meet the highest industry standards for quality and performance.

Medical Plastic Injection Molding Materials Available

| PEEK

PEEK (Polyether Ether Ketone) is highly suitable for medical plastic injection molding due to its excellent biocompatibility, high temperature resistance, and chemical stability. It can withstand harsh environments without compromising strength or durability. PEEK is commonly used for medical implants, surgical instruments, and drug delivery systems. For example, PEEK is used in orthopedic implants, like spinal fusion devices, and in components for diagnostic equipment due to its strength and reliability.

|

|

|

Radel® Radel® (Polyphenylsulfone) is ideal for medical plastic injection molding due to its excellent chemical resistance, high strength, and thermal stability. It maintains performance in harsh environments, making it suitable for critical medical applications. Radel® is used in components like sterilization trays, surgical instruments, and fluid handling parts. For example, it’s commonly found in diagnostic devices and drug delivery systems, offering durability and resistance to repeated autoclave sterilization.

|

|

| TPE

TPE (Thermoplastic Elastomers) are ideal for medical plastic injection molding due to their flexibility, biocompatibility, and ease of processing. They provide excellent elasticity, impact resistance, and chemical resistance. TPEs are commonly used in medical applications such as soft-touch grips, seals, and gaskets. For example, TPEs are used in medical tubing, catheters, and syringe components due to their comfortable feel and ability to withstand repeated use.

|

|

| Ultem®

Ultem® (Polyetherimide) is ideal for medical plastic injection molding due to its excellent thermal stability, high strength, and resistance to chemicals and radiation. It maintains performance in extreme conditions, making it suitable for medical applications. Ultem® is commonly used in diagnostic equipment, drug delivery systems, and surgical instruments. For example, it is used in components like ventilator parts and sterilizable medical device housings due to its durability and high-performance properties.

|

|

| PSU

PSU (Polysulfone) is ideal for medical plastic injection molding due to its excellent chemical resistance, high-temperature stability, and inherent toughness. It is biocompatible and can withstand sterilization processes, making it perfect for medical applications. PSU is commonly used in the production of medical device housings, diagnostic equipment components, and sterilization containers. For example, PSU is used in surgical trays and dialysis equipment due to its strength and resistance to harsh chemicals.

|

|

| Delrin®

Delrin® (Polyoxymethylene) is ideal for medical plastic injection molding due to its excellent mechanical strength, wear resistance, and low friction properties. It provides high precision and dimensional stability, making it perfect for complex medical components. Delrin® is commonly used in the manufacture of medical device housings, surgical instruments, and connectors. For example, it is used in orthodontic appliances, infusion pump components, and diagnostic devices due to its durability and performance under stress.

|

|

| Lexan®

Lexan® (Polycarbonate) is ideal for medical plastic injection molding due to its high impact resistance, optical clarity, and durability. It is also heat-resistant and has excellent dimensional stability. Lexan® is widely used for medical device housings, such as those for diagnostic equipment, and for transparent components like safety shields or surgical trays. Its strength and clarity make it a top choice for critical medical applications.

|

|

| PEBAX®

PEBAX® is an ideal material for medical plastic injection molding due to its excellent elasticity, abrasion resistance, and chemical stability. It also offers good biocompatibility, making it suitable for medical devices. PEBAX® is commonly used in the manufacturing of flexible medical tubing, catheters, and medical seals. For example, it’s used in blood catheter systems and other flexible, durable components that require high performance in challenging medical environments.

|

|

|

ABS ABS (Acrylonitrile-Butadiene-Styrene) is a popular material for medical plastic injection molding due to its excellent impact resistance, strength, and ease of processing. It is ideal for manufacturing complex parts with high precision. ABS is widely used in medical devices like housings for diagnostic equipment, surgical instruments, and patient monitoring systems. For example, ABS is commonly used for making durable, lightweight casings for portable medical devices.

|

|

Medical Plastic Injection Molding Finishing Options

| Name | Description | Can be Applied with |

|---|---|---|

| SPI Surface Finish | SPI surface finishes include A1, A2, and A3 grades, offering different smoothness and gloss levels. | Medical device housings, syringes, surgical instruments, and other parts requiring varying levels of gloss. |

| Mirror Polishing | Mirror polishing provides a high-gloss, smooth surface. | Surgical instruments, medical device housings, drug delivery devices, and parts requiring a mirror finish. |

| EDM Texturing | Electrical Discharge Machining (EDM) textures provide fine surface patterns, enhancing friction or aesthetics. | Surgical instrument handles, medical device functional surfaces, and medical containers. |

| VDI Surface Texture | VDI (Verein Deutscher Ingenieure) standard textures provide various surface patterns for different functional needs. | Medical instrument housings, surgical instruments, and parts needing specific texture. |

| Bead Blasting | Bead blasting creates a fine surface texture, improving tactile feel or reducing reflections. | Medical handles, housings, or parts requiring reduced light reflection. |

| Anodizing | Anodizing enhances the corrosion resistance and hardness of aluminum materials. | Medical device structural components, especially aluminum-based medical parts. |

| Plating | Plating provides corrosion resistance and improves conductivity, typically using gold, silver, or nickel. | Medical instrument contact parts, electrical contacts, and conductive components. |

| Coating | Coating adds protection to parts, improving wear resistance, chemical resistance, and more. | Drug delivery systems, medical instrument housings, and wear-resistant components. |

Medical Plastic Injection Molding FAQs

Medical Plastic Injection Molding -Definitive Guide

In the following guide, you will know everything about medical plastic injection molding.

The use of durable, reliable, and FDA-compliant medical plastic materials to manufacture medical parts and equipment is the essence of medical injection molding. As medical plastic injection molding is low-cost, it is suitable for mass production and applications that require consistency and tight tolerances. The FDA-approved medical device prototype development and laboratory testing also use the molding process of medical injection molding.

Nowadays, plastic injection molding has been widely used in the medical industry and provides many advantages for various applications. Medical-grade plastic injection molding has been used in medical devices, laboratories, and facilities equipment, components. The process of injection molding can exactly meet the regulatory requirements of the medical industry.

1. Benefits of Medical Device Injection Molding

It has been proved that medical plastic injection molding is one of the most effective ways to achieve the quality and specifications they need in a cost-effective manner. Medical device plastic injection molding is used in the following applications:

- Implantable components

- Beakers, test tubes, and other containers

- Housings and casings for medical and laboratory equipment

- Surgical equipment and components

- Drug delivery equipment and components

- Orthopedics

These are just a few methods used in plastic injection molding for medical devices. The plastic injection molding process of medical parts can be applied to almost any field. Durable, sterile-friendly parts require large amounts and special accuracy in production.

During the injection molding process, suppliers and manufacturers in the medical industry have gained several benefits inherent in the process and available materials. These benefits include:

1) Cost-effectiveness

The characteristics of injection molding make it a more cost-effective manufacturing process, especially in mass production. When there is a large need for medical parts, plastic injection molding is always the first choice and the most cost-effective option.

2) Excellent precision

For medical device manufacturing, close tolerance production is very important, millimeters or even micrometers can affect the performance of medical components. Skilled plastic injection molding equipment can produce a large number of components and equipment, with extremely high accuracy and negligible differences from one piece to another.

[lwptoc min=”1″ skipHeadingLevel=”h3″ skipHeadingText=”*Medical Plastic Injection Molding|*Custom OEM & ODM Medical Plastic Injection Molding Solutions|*Explore Our Medical Plastic Injection Molding Capacities:|*Forehead Thermometer Housing|*Medical device box|*Hospital Disposable Plastic Kidney Emesis Basins Trays|*Disposable Vaginal Applicators|*Customized Plastic Hospital Urinal Mould|*Bulb Ear Syringes|*Disposable Oxygen Mask|*I.V. infusion set injection mold|*Disposable blood collection device|*Air Atomising Burner|*Featured Medical Components We Produced|*Medical Plastic Injection Molding Capabilities|*Explore Our Latest Medical Plastic Injection Molding Products|*Medical Plastic Injection Molding Materials Available|*Medical Plastic Injection Molding Materials Available|*Medical Plastic Injection Molding Finishing Options|*Medical Plastic Injection Molding FAQs|*Medical Plastic Injection Molding -Definitive Guide|*ABS|*PP|*PE|*PS|*PC|*Nylon|*PU|*PET|*PTFE|*HDPE|*ABS|*PP|*PE|*PS|*PC|*Nylon|*PU|*PET|*PTFE|*HDPE”]