Are you looking for China’s best injection molding manufacturers to satisfy your custom business? As we all know, real factories mean first-hand prices. However, when you are given so many choices, you may be bewildered and difficult to distinguish between them. In this article, Holly personally selected the top 10 real injection molding manufacturers in China, and they all have actual factories.

With advanced technology and a strict quality management system, they continue to promote the development of the injection molding process in China and occupy an important position in the global plastic manufacturing market. So if you want to do business directly with injection molding manufacturing companies, this guide will help you.

1. List of the 10 Chinese Injection Molded Parts Manufacturers

| NO | Company | Business Type | Website | Year Founded |

| 1 | China Plastic Products Co. | plastic injection molding manufacturer | chinaplasticproductsco.com | 1966 |

| 2 | Holly Plastic Parts | custom plastic injection molding manufacturer | hollyplasticparts.com | 2000 |

| 3 | 3Q Machining | plastic injection molding manufacturer | 3qmachining.com | 2016 |

| 4 | WayKen Rapid Manufacturing | Rapid prototyping manufacturer | waykenrm.com | 2006 |

| 5 | MGA Plastic | injection molding manufacturer | mgaplastic.com | over 15 years |

| 6 | Ruicheng Precision Mold | precision mold manufacturer | chinaruicheng.com | 2002 |

| 7 | PF Mold Co., Ltd. | high-precision injection molds manufacturer | pfmold.com | 2006 |

| 8 | Best Times Mould & Plastic Products | mold design and manufacturing services supplier | besttimes-mould.com | 2007 |

| 9 | RT Prototype | Rapid prototyping manufacturer | rtprototype.com | 2004 |

| 10 | Rubber Plastic Parts | custom rubber and plastic components manufacturer | rubberplasticparts.com | 1998 |

2. Top 10 Injection Molded Parts Manufacturers in China

Let us look at the top 10 Injection Molded Parts Manufacturers in China

Top 1: China Plastic Products Co.

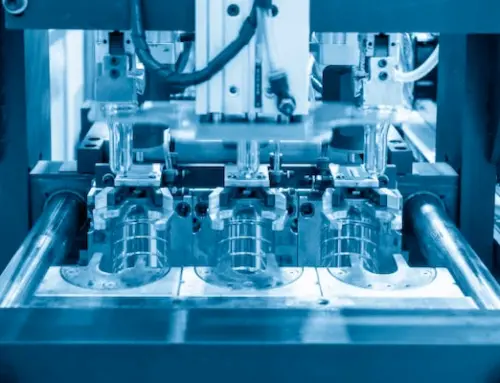

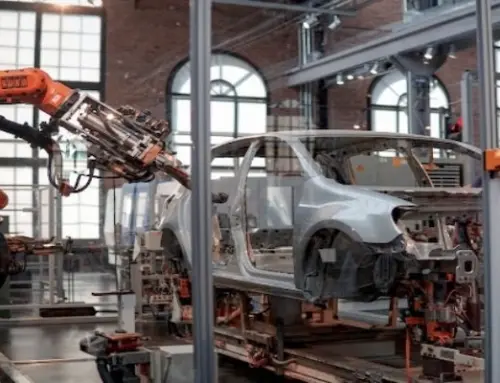

China Plastic Parts, Inc. is a 47-year-old veteran precision plastic parts injection mold maker catering to automotive, medical, and consumer electronic markets. The vertically integrated manufacturer from China provides overseas customers with manufacturing capabilities ranging from mold design to injection molding, overmolding, insert molding, and post-processing.

Their factory is fitted with more than 60 injection molding machines of 50-800 tons clamping force that can produce parts weighing between less than 1g and more than 3kg. The company operates a wide variety of engineering-grade thermoplastics like ABS, PA66, PC, POM, and TPE and complies with ISO 9001 quality system standards.

China Plastic Parts also provides secondary operations such as ultrasonic welding, pad printing, and custom assembly, thereby being a one-stop-shop for OEMs worldwide. A case study of an interesting client was that of a European automotive electronics manufacturer, which hired the company to develop a complex multi-component housing via insert molding. The project achieved a 22% cost saving in assembly and product durability. Their technical capability, quick lead times, and quality output still make them a good supplier for global injection molded part sourcing.

Website: chinaplasticproductsco.com

Founded: 1966

Location: China

Products: Plastic injection molded parts, blow-molded components, plastic extrusions.

Top 2: Holly Plastic Parts

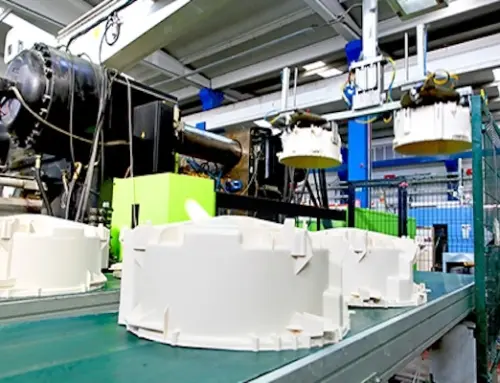

Holly Plastic Parts is an expert China plastic injection molding factory that has over 15 years of production experience. Holly has a 6,000 square meter workshop and over 50 sets of the injection molding machines with 50 to 800 tons clamping force, with which they can manufacture small precise parts and big structure parts.

Holly provides turnkey manufacturing solutions from mold development, mold tooling, plastic injection molding, and secondary operations such as ultrasonic welding, pad printing, and assembly. It is ISO 9001 certified and handles a range of engineering plastics such as PC, ABS, PP, PA6, PBT, and TPE for uses such as electronics, automotive, medical, and domestic appliances.

Sophisticated processes like insert molding, gas-assisted molding, and overmolding are offered to provide for complex part requirements. Holly can deliver over 1 million parts per month and accommodates both prototype and high-volume production demands.

In a recent case, Holly worked with a Japanese home appliance manufacturer to create precision switch panels using high-gloss PC/ABS material. By taking advantage of better mold design and process control, Holly reduced the cycle time by 18% and removed visible flow marks, enhancing the look and marketability of the product.

Website: https://www.hollyplasticparts.com/plastic-injection-molding/

Founded: 2000

Location: China

Products: Injection molded parts, CNC machined components, rapid prototypes.

Top 3: 3Q Machining

3Q Machining is a one-stop precision manufacturing company in Dongguan, China, providing services of plastic injection molding and CNC machining, die casting, and 3D printing. It has over 10 years of manufacturing experience and ships products to customers all over the world in the automotive, robotics, consumer electronics, and medical device industries.

3Q owns a 5,000 square meter state-of-the-art factory with more than 30 injection moulding machines with capacities ranging from 80 to 450 tons that can produce parts with weights ranging from 1g to 2kg. They possess single cavity moulds and multi cavity moulds, rapid tooling, insert mould and overmoulding. They do some processing on materials such as ABS, PA6/66, PC, POM, and TPU. They are ISO 9001 certified and enjoy tight tolerance control of up to ±0.02 mm.

Apart from molding, 3Q also has in-house mold tool manufacturing, post-molding (such as laser engraving and silk printing), and product assembly. Their team supports customers from design verification to production runs and offers DFM and mold flow analysis for complex projects.

One of those high-profile collaborations was with a German start-up medical device company with which 3Q Machining collaborated for low-volume production of disposable surgical instrument housings. Using rapid tooling in conjunction with tight-tolerance molding, 3Q allowed the customer to bring the product to market 30% faster without compromising on quality.

Website: 3qmachining.com

Founded: 2016

Location: China

Products: CNC machined parts, rapid prototypes, low-volume production parts.

Top 4: WayKen Rapid Manufacturing

WayKen is an industry-leading rapid manufacturing and injection molding company located in Shenzhen, China. The company is a prototype and low-volume production specialist and has customers in the automotive, aerospace, consumer electronics, and medical fields. WayKen, with more than 20 years of experience in the industry, delivers end-to-end solutions from product design to on-demand production.

The company owns 6,000 square meter of plant with 20+ injection molding machines ranging from 60 to 500 tons suitable for small- to medium-sized molded components. WayKen accepts a wide range of materials such as ABS, PC, PA, PMMA, and POM. In addition to this, they possess experience in complex molding techniques such as insert molding, overmolding, and rapid bridge tooling.

ISO 9001 accredited, WayKen emphasizes accuracy and quick turnaround. Its tooling service has the capability of fabricating injection-molded parts in 7 days, which makes it suitable for engineering validation testing and pre-prod runs. Some of the post-processing services offered in-house include polishing, painting, laser etching, and assembly.

In a recent project, WayKen collaborated with a U.S.-based automotive tech company to create an integrated sensor housing prototype with a tight development schedule. Through rapid mold making and short-cycle production, WayKen delivered 1,000 functional units within 14 days, significantly reducing the client’s product validation schedule.

Website: waykenrm.com

Founded: 2006

Location: Shenzhen, China

Products: CNC prototypes, 3D printed parts, vacuum casting components.

Top 5: MGA Plastic

MGA Plastic is a Chinese injection molding factory with over 15 years’ experience in specialized plastic parts supply with tailor-made services to overseas buyers in the automotive, consumer electronics, lighting, and industrial equipment markets. MGA owns a full 5,500-square-meter Shenzhen factory, offering one-stop service from mold design and tooling to injection molding and end-product assembly.

MGA has over 25 injection molding machines ranging from 50 to 500 tons that enable them to mold components up to 750mm long and 2.5 kg in weight. They work with a variety of materials like ABS, PC, PA66, PBT, and TPE. They possess an in-house tool shop that enables them to provide rapid mold development, with production-ready tools shipped in as little as 10 days.

Certified to IATF 16949 and ISO 9001 standards, MGA Plastic is very sensitive to quality and traceability. Value-added operations involve 3D printing, pad printing, ultrasonic welding, and value-added packaging.

One recent instance was working with a Canadian smart lighting firm, which partnered with MGA to produce heat-resistant polycarbonate enclosures for outdoor LED luminaires. MGA developed the tool for UV-stable material optimization and delivered over 200,000 units with a defect rate of under 0.4%, allowing the customer to meet on-time retail demand during peak seasons.

Website: mgaplastic.com

Founded: over 15 years ago

Location: China

Products: Plastic injection molded parts, assemblies, and custom plastic components.

Top 6: Ruicheng Precision Mold

Xiamen Ruicheng Industrial Design Co., Ltd. is a China Xiamen-based professional rapid manufacturing and plastic injection molding company. Ruicheng has over 12 years of experience in the industry with expertise in rapid tooling and small-to-medium-size-volume plastics manufacturing for automotive, medical, electronics, and home appliances sectors.

It owns a 3,000 square meter plant with more than 20 injection machines ranging from 50 to 400 tons. It produces different kinds of engineering plastics such as ABS, PC, PA6, PMMA, and TPU with mold tolerances of ±0.01 mm.Ruicheng’s forte is rapid mold development—allowing them to provide fully functional tools in as little as 7–10 days.

Ruicheng offers a one-stop service that covers industrial design, DFM analysis, CNC prototyping, rapid mold making, injection molding, and also post-processing services such as painting, silk-screening, and final assembly. Ruicheng is an ISO 9001 certified firm and specializes in short-cycle development for time-limited projects.

For a recent project with a U.S.-based electronics firm, Ruicheng produced 5,000 sets of bespoke connector housings in three weeks using rapid injection mold. The project, from design to shipping, was completed in three weeks, which allowed the customer to meet an ambitious product launch schedule.

Website: chinaruicheng.com

Founded: 2002

Location: Dongguan, China

Products: Plastic injection molds, molded parts, custom tooling solutions.

Top 7: PF Mold Co., Ltd.

PF Mold Co., Ltd. is an injection mold maker and parts manufacturer based in Shenzhen, China. Established over 20 years ago, the organization provides one-stop injection molded parts solution to automotive, consumer electronics, home appliance, and medical industries. PF Mold possesses a 7,000-square-meter workshop with over 40 injection molding machines from 50 tons to 600 tons, which can manufacture parts with a weight of 0.1g to 3,500g.

The company possesses a well-furnished mold workshop that is equipped with CNC, EDM, and wire-cut machines for quick mold making and high-precision tooling production. PF Mold works with a range of thermoplastics, including PC, ABS, PP, PA, TPE, and PBT, and adheres to ISO 9001 quality systems. Their mold services cover everything from mold design, DFM check, mold making, mass production, and afterward processing such as pad printing, assembly, and custom packaging.

In one of its recent projects, PF Mold partnered with a European household appliance company to design and produce a multi-cavity mold for dishwasher components. With its improved cooling design and high-precision cavity position, PF Mold helped the customer decrease the cycle time by 20% and improve dimensional stability, which made a large-volume product launch successful.

Website: pfmold.com

Founded: 2006

Location: Shenzhen

Products: Injection molds, molded plastic parts, rapid prototypes.

Top 8: Best Times Mould & Plastic Products

Best Times Mould & Plastic is a high-precision plastic injection moulding and mold making firm located in Dongguan, China. Established over 18 years ago, the company provides one-stop solution from mould making to batch production for global customers in the automobile, electronics, medical and consumer products sectors.

Best Times has a factory of 6,500 square meters with 36 injection machines ranging from 60 to 2,500 tons clamping force. They are able to produce small precision parts to large intricate parts with product tolerances as tight as ±0.025 mm. They also have an in-house toolroom with high-speed CNCs, EDMs, and CMMs that allow them to acquire mold tolerances as high as ±0.01 mm.

The firm is ISO 9001 and IATF 16949 certified and maintains a special interest in high-cavity molds, multi-shot molding, and custom-engineered solutions. Overmolding, insert molding, ultrasonic welding, and assembly are also part of their services. Best Times has delivered over 5,000 molds and serves customers in more than 30 countries.

In a recent project with a U.S. automotive client, Best Times produced a dual-material dashboard component using 2K injection molding. The solution improved part strength and aesthetics while reducing assembly time by 35%. Their engineering support and stable quality ensured smooth mass production for the client.

Website: besttimes-mould.com

Founded: 2007

Location: Shenzhen, China

Products: Plastic injection molds, custom-molded components, and assembly services.

Top 9: RT Prototype

Ruitai Mould is a reliable Shenzhen, China business that deals with plastic injection molding and rapid prototyping custom services. The business has over 15 years of experience and focuses on low and medium volume production, serving the automotive, consumer electronics, industrial equipment, and medical device industries.

Ruitai operates a 4,500-square-meter facility with more than 20 injection molders ranging from 60 to 500 tons which can produce detailed parts weighing from 1g to 2kg. Ruitai processes ABS, PC, PA, PBT, TPE, and PPS materials and offers tight tolerance molding and in-plant mold making. Ruitai is ISO 9001 certified and accepts production tooling and prototype tooling applications.

They offer rapid tooling services, insert and overmolding, short-run injection molding, and post-processing operations such as painting, laser etching, and product assembly. 7 to 20-day average project turnaround times make Ruitai a responsive business partner for fast-paced product development cycles.

In one such case, Ruitai partnered with an EU robotics startup to create 8,000 bespoke enclosures through a rapid aluminum mold. The work enabled the client to test and ramp early-stage production batches with commercial-grade, allowing them to accelerate investor demos and pre-orders.

Website: rtprototype.com

Founded: 2004

Location: Shenzhen, China

Products: CNC machined prototypes, 3D printed components, rapid production parts.

Top 10: Rubber Plastic Parts

Rubber Plastic Parts Co., Ltd. is a Ningbo, China-based professional OEM/ODM custom plastic injection molded and rubber parts manufacturer. Having more than 15 years of industry experience, the company provides one-stop OEM/ODM services to customers in automotive, consumer, electrical appliances, and industrial equipment companies.

The factory occupies 5,000 square meters and has over 30 injection mold machines ranging from 80 tons to 400 tons. The company handles a vast range of materials like ABS, PC, PP, PA66, PBT, TPU, silicone rubber, and fluorosilicone, making it possible for them to support both plastic and rubber overmolding work. The monthly production capacity is over 1 million molded parts, with ISO 9001 and IATF 16949 certification to maintain quality control consistency.

In addition to plastic injection molding, the company provides in-house mold making, secondary operations (e.g., pad printing and ultrasonic welding), and customized packaging. Rubber Plastic Parts is also experienced in high-cavitation tooling of small and medium-sized components.

In one of their recent projects, they collaborated with a Southeast Asian home appliance company to create durable rubber-plastic hybrid seals for water purifiers. Because they could combine elastomeric and rigid materials within a single process, they were able to reduce parts by 40% and streamline the client’s assembly process.

Website: rubberplasticparts.com

Founded: 1998

Location: Hangzhou

Products: Custom rubber parts, plastic injection molded components, seals, and gaskets

3. How to Select a Reliable Plastic Parts Manufacturer in China?

Then we are going to give you some system approaches and theoretical examples on how to select a good plastic parts factory in China.

1) systematic approach

A correct injection molded components manufacturer in China has to be chosen based on a systematic approach to ensure quality, reliability, and cost savings. The following are comprehensive methods for the correct choice:

1. Assess Manufacturing Capabilities

- Machine Availability

- Material Expertise

- Production Scale

- Specialized Processes

2. Review Certifications and Compliance

- ISO 9001 Certification

- Industry-Specific Standards

- Material Compliance

3. Evaluate Quality Control Practices

- Inspection Procedures

- Testing Capabilities

- Sample Evaluation

4. Analyze Tooling and Mold Design Expertise

- In-House Tooling

- Mold Maintenance

- Mold Life Expectancy

5. Check Experience and Industry Focus

- Industry Specialization

- Portfolio Review

- Years in Business

6. Inspect Lead Times and Production Scalability

- Prototype Speed

- Turnaround Time

- Scalability

7. Understand Cost Transparency

- Mold Cost

- Unit Cost

- Hidden Fees

8. Investigate Communication and Support

- Language Skills

- Response Time

- Dedicated Account Manager

9. Verify Intellectual Property (IP) Protection

- NDA Agreements

- Tooling Ownership

- Registered Designs

10. Conduct an On-Site Visit or Virtual Audit

- Facility Tour

- Third-Party Audit

11. Check References and Reviews

- Customer References

- Online Reviews

- Industry Reputation

12. Negotiate Flexible Terms

- Payment Terms

- Order Flexibility

- Long-Term Collaboration

Request Trial Orders: Start with a small production run to evaluate their capabilities, quality, and communication before committing to larger projects.

2) Some examples of how to select a reliable plastic parts manufacturer in China

Following are the examples of implementing the steps to select the right injection molded parts makers in China from real-life situations and hypothetical ones:

Example 1: Automotive Components Manufacturer

Situation: You need injection-molded plastic parts for car interiors with high tolerances and good durability.

Steps:

- Shortlist companies specializing in automotive-grade plastics, such as PF Mold Co., Ltd. or Ruicheng Precision Mold.

- Check if they comply with IATF 16949 automotive standards.

- Request samples of similar parts they’ve produced and inquire about the mold life expectancy for high-volume production.

- Conduct a third-party audit of their facility or ask for a virtual factory tour.

Example 2: Consumer Electronics Manufacturer

Scenario: You need precise, aesthetically finished plastic casings for a new consumer electronics product.

Steps:

- Choose a firm that specializes in electronics components, e.g., Holly Plastic Parts or Best Times Mould.

- Ensure they can provide high-gloss surface finishes and insert molding for integration of metal components.

- Ask for their quality control procedures, such as prototype dimensional inspection reports.

- Negotiate a test order of 500 pieces to try out quality, lead time, and communications.

Example 3: Medical Device Manufacturer

Scenario: You require biocompatible plastic parts for a medical device.

Steps:

- Look for manufacturers with a track record of working with medical-grade plastics, such as WayKen Rapid Manufacturing (waykenrm.com).

- Verify their compliance with ISO 13485 for medical devices and FDA-approved materials.

- Request full documentation of material sourcing and processing.

- Assess their capability to undertake testing, such as tensile strength and surface roughness tests.

Example 4: Start-Up Needing Rapid Prototyping

Scenario: As a start-up, you need prototypes of an innovative product quickly and affordably.

Steps:

- Work with a rapid prototyping and injection molding firm, such as RT Prototype or Holly Plastic Parts.

- Ask for fast turnaround time for prototypes that are CNC machined or 3D-printed molds before committing to a full production run.

- Negotiate adjustable order quantities when scaling up production.

Example 5: IP Protection for a Unique Design

Scenario: You’ve developed a patented design and need a manufacturer with strong IP protection measures.

Steps:

- Identify a manufacturer willing to sign an NDA, such as Rubber Plastic Parts.

- Ensure that you will own the mold and have it returned in case the collaboration is discontinued.

- File your design patents in China to reinforce legal protection.

Example 6: Large-Scale Production of Packaging Products

Scenario: You require high-volume production of plastic containers for the food industry.

Steps:

- Locate companies with experience in packaging solutions, e.g., MGA Plastic.

- Assure them that they employ food-grade materials and meet RoHS or FDA compliance standards.

- Verify their production capacity to meet millions of parts annually.

- Negotiate long-term contracts for stable prices and priority production.

Using these clear examples, you can make your strategy industry specific, product requirement, and priority specific. This leads you to select a right manufacturer for your requirement.

4. Conclusion

Identifying a reliable injection molding supplier in China is a job that requires patience, work, and strategic thinking. By following the steps outlined in this guide, you will be adequately prepared to manage the complexities of sourcing from China’s gigantic manufacturing base. So are you ready to begin your journey to find the top injection molding suppliers in China? With this guide, you’ll be well-prepared to begin the journey towards a successful manufacturing partnership.

Leave A Comment