Are you struggling to find the best Chinese 3D metal printing companies? In recent years, China has achieved much in the additive manufacturing field — it has revolutionized the manufacturing industry with customized, complex products and become a leader in 3D printing technology. Yet finding the best companies remains a daunting challenge. So, stay patient: here, we will introduce the top 10 best 3D metal printing manufacturers in China.

1. List of the Top 10 Metal 3D Printing Service Companies in China

| NO. | Company | Website | Year Established |

| 1 | Holly | hollyplasticparts.com | 2000 |

| 2 | China-3DPrinting | china-3dprinting.com | 2012 |

| 3 | Facfox | facfox.com | 2015 |

| 4 | Unionfab | unionfab.com | 2014 |

| 5 | Eplus3D | eplus3d.com | 2014 |

| 6 | JTR Machine | jtrmachine.com | 2013 |

| 7 | Aixi Hardware | aixihardware.com | 2010 |

| 8 | Be-Cu | be-cu.com | 1995 |

| 9 | Deep Mould | deepmould.net | 2008 |

| 10 | APA Prototype | apa-proto.com | 2014 |

2. Top 10 Metal 3D Printing Service Companies in China

The following is detailed information on the top 10 metal 3D printing service companies in China.

Top1: Holly

Holly Plastic Parts is a Chinese expert injection molding factory of plastic parts with more than 15 years’ experience serving global OEM and industrial customers. From a 6,000-square-meter factory building, the company is equipped with well over 50 injection molding machines with clamping tonnage from 50 to 800 tons. Holly’s specialty is high-accuracy plastic component production, with end-to-end services including mold design, tooling, injection molding, secondary processing, and assembly. With a production capability of over 1 million molded parts per month, the factory has ISO 9001 certification to deliver end-to-end quality at each stage.

Holly Plastic Parts has the ability to mold a wide range of materials such as ABS, PC, PP, PA, PBT, and high-performance materials like PEEK and PPS. Apart from that, they also provide advanced molding techniques such as overmolding, insert molding, gas-assisted molding, and cleanroom molding for medical and electronic applications. They ship to the automotive, consumer electronics, medical devices, and smart home systems industries.

One of such initiatives was with Tontec, a global injection molding firm, which partnered with Holly to produce precision overmolded sensor housing. Holly provided over 200,000 units with fewer than 0.3% defect, providing value to Tontec’s high-volume production program. Holly’s technical support and quality consistency made them an extension of Tontec’s global supply base.

Website: https://www.hollyplasticparts.com/3d-printing/

Founded:2000

Location: Jiaxing, Zhejiang

Products:

- 3D Printing Prototype

- CNC Machining Service

- Vacuum Casting Service

Top 2: China-3DPrinting (Shenzhen JR Technology Co., Ltd.)

China-3Dprinting.com, a property of Shenzhen JR Technology Co., Ltd., is one of China’s leading metal 3D printing industrial-grade service providers. The company has built advanced capabilities in aerospace, medical, automotive, robotic, and consumer electronics industries with over 10 years of experience. They own more than 30 industrial 3D printers such as SLM (Selective Laser Melting) and DMLS (Direct Metal Laser Sintering) machines to enable precise and scalable production with more than 1,000 printed parts per day. They offer end-use production and functional prototyping with the materials of titanium, aluminum, stainless steel, Inconel, and tool steels.

The company provides the whole process of production—3D CAD design, metal printing, post-processing (heat treatment, CNC machining, polishing), to surface finishing and inspection—with quality and consistency across projects. Their engineering group provides DfAM (Design for Additive Manufacturing) consultation to help clients maximize product structure and reduce lead time and cost.

One of the most significant client cases is Tontec, a global market leader in plastic injection moulding. In Tontec’s high-strength mould inserts, china-3dprinting.com produced customized Inconel 718 inserts with internal cooling channels through metal 3D printing. The solution saved 30% in cooling time, improved tool life, and helped Tontec increase production efficiency in multiple locations worldwide.

Website: china-3dprinting.com

Founded: 2012

Location: China

Products:

- 3D printing services

- rapid prototyping

- additive manufacturing solutions

- metal and polymer parts

Top 3: FacFox

FacFox is a China-first online digital manufacturing platform that offers one-stop 3D printing, CNC machining, injection molding, and casting services. FacFox built a network of over 50 plants and over 1,000 machines in China with over 2 million monthly production capacity to serve customers worldwide.

Specializing in both metal and plastic 3D printing, FacFox utilizes advanced technologies such as Selective Laser Melting (SLM), Direct Metal Laser Sintering (DMLS), and Multi Jet Fusion (MJF). Their material offerings include stainless steel, aluminum, titanium, copper, and engineering-grade polymers like PEEK and PA12. FacFox’s Insta3DP platform allows clients to obtain instant quotes by uploading 3D models, streamlining the production process.

A notable client case involves Ashley Furniture, which utilized FacFox’s services to produce a replacement vacuum retainer ring for a drilling machine. By 3D scanning the original part and printing a replacement, Ashley Furniture reduced costs from $700 to just $1, demonstrating FacFox’s ability to deliver cost-effective solutions rapidly.

FacFox’s commitment to quality, efficiency, and innovation positions it as a trusted partner for businesses seeking reliable and scalable manufacturing solutions.

Website: facfox.com

Founded: 2014

Location: Hangzhou, China

Products:

- 3D printing

- CNC machining

- injection molding

- metal casting

- sheet metal fabrication

Top 4: Unionfab

Unionfab is the biggest industrial-grade 3D printing manufacturer in Asia, boasting more than 1,000 cutting-edge machines stationed across five enormous China production mega-complexes. The huge equipment fleet includes more than 540 SLA machines, supported by SLS, SLM, MJF, FDM, DLP, and PolyJet systems that enable the mass production of more than 2 million parts annually.

With over 800 experts on its team, Unionfab has the entire package of services from rapid prototyping to mass production, catering to the automotive, aerospace, medical, and consumer electronics industries. They specialize in CNC machining, vacuum casting, and injection molding for a one-stop trouble-free service for various manufacturing needs.

One of the major customers, Schneider Electric, has been associated with Unionfab since 2014. Throughout all these years, Unionfab has delivered timely delivery of top-class, advanced components, significantly contributing to the R&D efforts and product development of Schneider Electric.

Unionfab’s commitment to quality can be seen through its ISO 9001-certified plants and below 0.5% quality complaint rate. It boasts a worldwide presence of over 170 countries with a 95% on-time delivery, and as such, it is a trusted partner to firms around the world in search of efficient and reliable manufacturing services.

Website: unionfab.com

Founded: 2013

Location: China

Products:

- 3D printing (SLA, SLS, MJF)

- rapid prototyping

- small-batch production

Top 5: Eplus3D

Founded in 2014 in Hangzhou, China, Eplus3D is also one of the most renowned Chinese industrial-grade metal 3D printing and additive manufacturing solution suppliers. With over 30 years of AM technology R&D experience of its founding members, with expertise in powder bed fusion technologies like SLM and DMLS, Eplus3D is a industry leader. Their 3D metal printers are from EP-M150 to EP-M650 and have the capacity to print part sizes of up to 650 × 650 × 800 mm. They have over 600 systems installed around the world and serve big industries like aerospace, automotive, energy, and medical.

Its end-to-end solution consists of hardware, software, material, and post-processing. Available materials are titanium alloys, stainless steels, aluminum alloys, Inconel, cobalt-chrome, and copper alloys. Its high-temperature field control and dual-laser designs produce high-density, dimensionally stable components with precise uniformity.

A standout case is Tontec, a global plastic injection molding group. Tontec collaborated with Eplus3D to develop conformal-cooled mold inserts using the EP-M260 metal 3D printer. The result was a 25% cycle time reduction and extended tooling lifespan in high-volume production. By partnering with Eplus3D, Tontec achieved better cooling efficiency in molds with complex geometries, proving the value of metal AM integration in traditional injection workflows.

Website: eplus3d.com

Founded: 2014

Location: Hangzhou, China

Products:

- Industrial 3D printers (metal and polymer)

- Additive manufacturing solutions

Top 6: JTR Machine

JTR Machine is China’s highest ranked digital manufacturing solution company specializing in end-to-end metal 3D printing, CNC machining, sheet metal forming, and rapid prototyping. It has over 10 years of experience and a high-tech facility housing over 80 CNC machines and a few SLM and DMLS 3D printers. Its metal 3D printing service covers metal materials like stainless steel, titanium, aluminum, Inconel, and tool steel for prototyping and low-volume production.

JTR can manufacture in excess of 5,000 parts monthly with lead time of 3–7 days. They also provide full-service project management—design review and material choice, post-processing (heat treating, machining, polishing, anodizing)—with extremely high accuracy and consistency. The company is ISO 9001 certified and supplies customers from a variety of markets such as automotive, robotics, medical, and consumer electronics.

Tontec Group recently partnered with JTR Machine to produce complex internal mold components in Inconel 718 through metal 3D printing. Internally cooled components helped Tontec reduce cycle time by 22% and increase mold toughness. JTR’s fast delivery, design support, and cost-effective solutions made it an ideal partner for Tontec’s worldwide production needs.

Website: jtrmachine.com

Founded: 1995

Location: China

Products:

- CNC machining

- 3D printing

- metal fabrication

- rapid prototyping

Top 7: Aixi Hardware

AIXI Hardware is a precision manufacturing company based in Dongguan, China, which provides CNC machining, metal 3D printing, sheet metalworking, and rapid prototyping. AIXI was founded more than 15 years ago and provides tailored solutions for complex part geometry and metal parts with high performance. AIXI has a workshop of over 50 advanced machines, including metal 3D printers with Selective Laser Melting (SLM) technology. AIXI can deliver over 10,000 tailor-made parts per month with just 3-day lead times.

Their metal additive manufacturing solutions are Inconel compatible, stainless steel compatible, titanium compatible, and aluminum alloy compatible with a ±0.05 mm dimensional tolerance. They provide the full spectrum of services ranging from 3D review of design to DfAM design of additive manufacturing for optimizing, prototyping, end production, and post-processing such as heat treatment, CNC finishing, and surface coating. AIXI supports low-to-medium run volumes, which is ideal for industrial end customers in the automotive, aerospace, and consumer electronics industries.

Tontec collaborated with AIXI Hardware to produce metal mold inserts with integrated conformal cooling channels for one of its high-cavity tooling applications. By using 3D-printed Inconel inserts, Tontec reduced cycle times by 28% and improved mold service life, achieving better temperature control and faster production. AIXI’s fast turnaround and engineering support made the project highly successful.

Website: aixihardware.com

Founded: 2010

Location: Dongguan, China

Products:

- CNC machined components

- injection-molded parts

- rapid prototyping

Top 8: Be-Cu

BE-CU is a professional custom metal fabrication company based in Shenzhen, China, with over 20 years of precision CNC machining and metal 3D printing experience. The company boasts a 10,000+ square meter plant with over 100 CNC machines and advanced SLM 3D printing facilities, enabling intricate prototype and low-volume metal part manufacturing with excellent accuracy. Monthly capacity is over 30,000 parts, and lead times as little as 3–5 days.

BE-CU is a stainless steel, copper, titanium, aluminum, Inconel, and high-performance alloys functional 3D printing firm. They provide design consulting, additive manufacturing, post-processing (heat treatment, polishing, CNC finishing), and strict quality control according to ISO 9001 standards. They cater to challenging markets like medicine, automobile, electronics, and aerospace and provide both rapid prototyping and low-series production.

One of the high-profile partnerships was Tontec collaborating with BE-CU to manufacture precision conformal-cooled mold inserts using 3D-printed copper alloys. The inserts enhanced thermal conductivity and cycle time in high-volume injection molding by a significant amount. Tontec reduced the production efficiency by 25% by optimizing insert geometry and adding internal cooling channels. BE-CU’s fast turnaround time, engineering expertise, and commitment to quality was a reliable partner for complex tooling solutions.

Website: be-cu.com

Founded: Not specified

Location: China

Products:

- CNC machining

- die casting

- injection molding

- rapid prototyping

Top 9: Deep Mould

Deep Mould is a one-stop-shop, China-located rapid prototyping and precision manufacturing company. Deep Mould has been involved in metal 3D printing, CNC machining, injection molding, and vacuum casting for the past more than 15 years. They operate out of a 5,000+ square meter facility and possess more than 60 CNC machines, SLM 3D printers with advanced technology, and inspection machines. They produce over 20,000 specialized parts a month for automotive, medical, aerospace, and electronics clients.

Deep Mould offers metal 3D printing for the production of high-strength metals such as titanium, stainless steel, aluminum, and Inconel. From inspection of 3D files to printing, through post-processing such as heat treatment, CNC finish, and surface polish, they provide end-to-end manufacturing cycle solutions. ISO 9001-qualified quality control and engineering assistance enable them to provide bespoke solutions for prototypes and low-series production batches to ±0.02mm tolerances.

In one of its latest collaborations, Tontec teamed up with Deep Mould to minimize high-cavity mold inserts using Inconel 718 metal 3D printing. Conformal cooling channels in the new mold inserts eliminated 30% of the injection cycle time and significantly improved the product consistency. Deep Mould’s quick lead time, technical skills, and high-capacity post-processing made it a good fit for Tontec’s global tooling projects.

Website: deepmould.net

Founded: 2008

Location: Dongguan, China

Products:

- Plastic injection molds

- die casting molds

- rapid prototyping

Top 10: APA Prototype

APA Proto is a prototyping and low-run manufacturing expert with more than 12 years’ experience working for customers based overseas. The company offers the full scope of services such as metal 3D printing, CNC machining, injection molding, sheet metal fabrication, and urethane casting. APA Proto operates a world-class manufacturing building with more than 70 machines, including over a Direct Metal Laser Sintering (DMLS) 3D printers. They have a monthly capacity to produce over 15,000 special parts and lead times as little as 5 days.

APA Proto’s metal 3D printing technology accepts stainless steel, titanium, Inconel, tool steel, and aluminum among other materials to create high-strength, intricate parts not achievable through conventional methods. APA Proto does it all project management-wise—from review of design and DfAM optimization to post-processing (machining, heat treatment, polishing, and anodizing). APA Proto delivers to the medical device, consumer electronics, automotive, and aerospace markets with ISO 9001-certified quality control across the board.

In one of its recent collaborations, Tontec turned to APA Proto to produce high-precision mold inserts made using DMLS-printed tool steel. Internal cooling channels optimized, the inserts reduced cycle time by 26% and improved heat efficiency. APA Proto’s engineering support and fast turnaround were instrumental in Tontec’s smooth adoption of the new tooling solution.

Website: apa-proto.com

Founded: 2014

Location: China

Products:

- Rapid prototyping

- CNC machining

- 3D printing

- injection molding

3. Metal 3D Printing Service in China FAQs

Below are some questions that are commonly asked about the metal 3D printing service in China.

1. What is metal 3D printing?

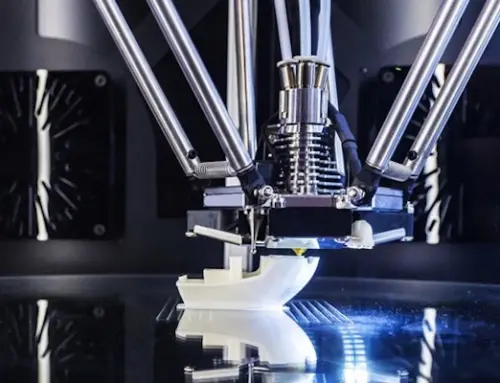

Metal 3D printing, also known as additive manufacturing, refers to an additive method that adds the material layer by layer to create three-dimensional metal parts from digital models. Some of the commonly applied technologies for metal 3D printing are Direct Metal Laser Sintering (DMLS), Selective Laser Melting (SLM), and Binder Jetting.

2. Which sectors use metal 3D printing in China?

Aerospace, automotive, medical devices, industrial tooling, and consumer electronics use metal 3D printing for accuracy, customization, and high-performance material needs.

3. What materials are available for metal 3D printing?

Some of the materials employed in China include:

- Stainless steel

- Aluminum alloys

- Titanium alloys

- Nickel-based superalloys (e.g., Inconel)

- Copper and copper alloys

- Tool steels

- Cobalt-chromium alloys

Each material is selected based on the specific requirement of strength, heat resistance, or corrosion resistance.

4. What are the typical lead times for metal 3D printing services in China?

Lead times can range from 3 to 10 days, depending on:

- Design complexity

- Material choice

- Quantity of parts being ordered

- Prototyping would typically be done in 3-5 days, and small-batch production would take a bit longer.

5. What are the advantages of choosing a Chinese provider for metal 3D printing?

Cost Effectiveness: Less costly than Western counterparts.

State-of-the-Art Equipment: Easy availability of the most modern equipments such as EOS, SLM Solutions, and Renishaw.

Rapid Turnaround: Quick lead times through massive industrial infrastructure.

Customization: High detailing capability to manufacture complex, customized products.

Export Know-how: Majority of the suppliers’ knowledge in exporting internationally with proper documentation.

6. How quality are Chinese 3D printed components from metal?

Chinese manufacturers are typically up to international standards, including:

- ISO 9001: Management systems for quality

- AS9100: For aerospace-level manufacturing

- Medical certifications: For biocompatibility

The components are typically checked with sophisticated methods like CT scanning and metrology for high-quality.

7. Can I order both prototypes and production parts?

Yes, most Chinese providers offer:

- Prototypes: For testing and verification of design.

- Small-Batch Production: Cost-effective for small series.

- Mass Production: Scalable solutions with good consistent quality.

8. How is metal 3D printing service pricing?

Pricing depends on:

- Material type (e.g., titanium is more expensive than aluminum).

- Size and number of parts.

- Design complexity.

- Post-processing requirements (e.g., polishing, heat treatment).

- Most suppliers quote online from CAD files.

9. Are post-processing services available?

Yes, most suppliers offer a lot of post-processing, for example:

Surface finishing (polishing, sandblasting, etc.)

Heat treatments for enhanced mechanical properties

Coatings (e.g., anodizing, plating)

CNC machining for tight tolerances.

10. How do I ensure intellectual property (IP) protection when outsourcing to China?

- NDAs (Non-Disclosure Agreements): Request signed NDAs before disclosing designs.

- Choose Reputable Businesses: Opt for certified suppliers with excellent records.

- Patent Registration: If concerned, have your designs registered in China before outsourcing.

11. What is the accepted file format for metal 3D printing?

Most accepted file types are:

Keep your files at high resolution for accurate manufacturing.

12. How do I find a good Chinese metal 3D printing supplier?

Research on the leading companies like Unionfab, Eplus3D, FacFox, and others.

Check reviews and certifications (like ISO, CE).

Request samples for quality testing.

Use sites like Alibaba or directly ask on company websites.

4. Conclusion

The above is our top ten list of metal 3D printing companies in China. They have opened the additive manufacturing sector with user-friendly solutions, precise digital technology, and differentiation in metal and resin 3D printing. Their investments in research and development, as well as their enormous patent libraries, give evidence of China’s pursuit of maintaining leadership status in this groundbreaking technology.

Leave A Comment