China LSR Injection Molding Manufacturer & Supplier

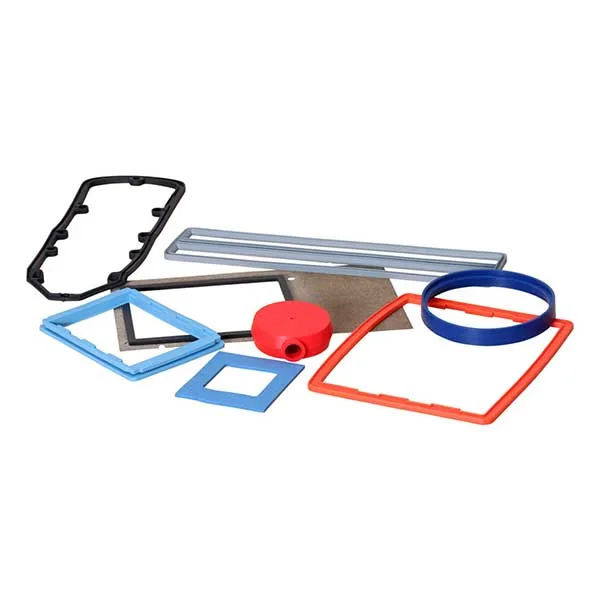

Holly Industries specializes in precision LSR injection molding for medical, automotive, electronics and consumer product markets. Utilizing state-of-the-art molding technology and stringent quality controls, we deliver multipurpose skin-similar silicone rubber components.

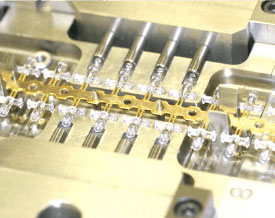

Our facilities cover complex geometry, thin-wall components, through to mass production. We have advanced LSR injection molding equipment and highly qualified engineers at your service to enable quick turnaround and reliable quality.

From prototype to mass production, Holly is cost-effective without compromising performance. Call us today to get premium LSR injection molding services that suit your best interests!

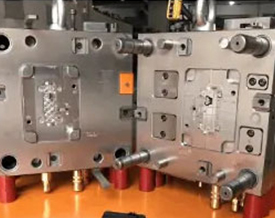

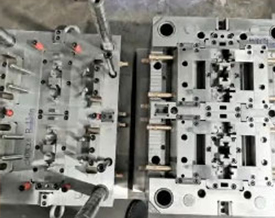

Explore Our LSR Injection Molding Molds

Holly offers precision molds for LSR Injection Molding, producing precision silicone rubber parts of high quality. Our product lines include single-cavity molds, multi-cavity molds, family molds and complex geometries molds for medical devices, automotive sealants, electrical connectors and consumer goods applications. With our sophisticated mold design and manufacturing capabilities allowing for high strength manufacturing at low cycle times with consistent part quality to cater to various industry requirements such as precision and reliability.

LSR Injection Molding Capabilities

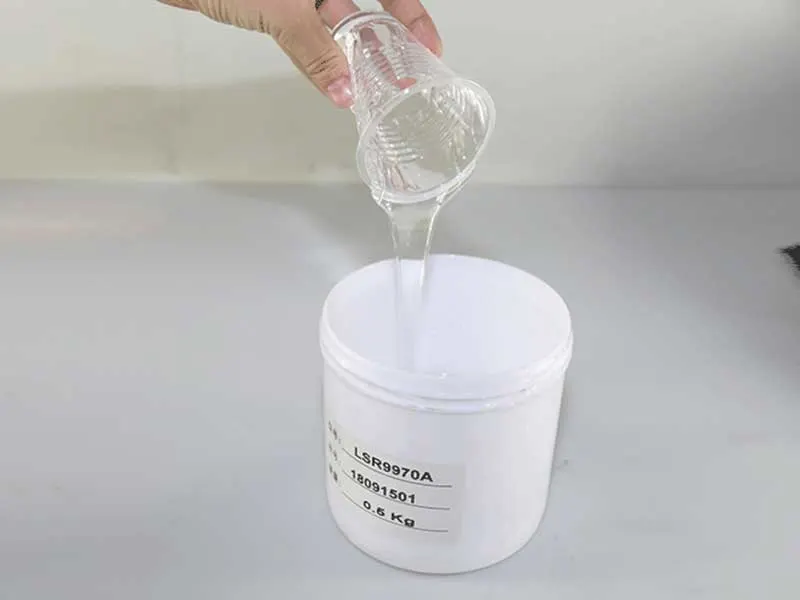

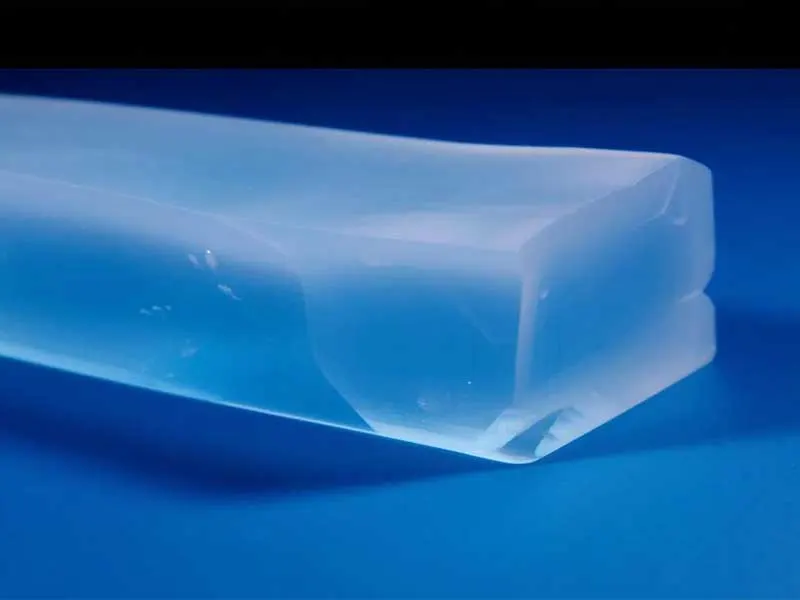

Material of LSR Injection Molding Available

| LSR

LSR (Liquid Silicone Rubber) is ideally suited for LSR injection molding, because of its higher flexibility, thermal stability, and flow into intricate molds. It cures quickly and maintains shape at very low or very high temperatures. LSR is in widespread use in

where reliability, biocompatibility, and precision are crucial.

|

|

| HCR

HCR (High-Consistency Rubber) is ideal for LSR Injection Molding due to its superior heat resistance, mechanical strength, and ability to retain its elasticity in harsh environments. Furthermore, its toughness and flexibility make it the ideal material for creating tough yet high-performance parts. HCR in actual use is applied throughout the automotive seal, industrial gasket, and high-temperature insulation markets where reliability and performance are critical. Its ability to exist under harsh conditions places it in the line of application for harsh industrial and automotive environments.

|

|

| FVMQ

FVMQ (Fluorosilicone Rubber) is particularly well suited to LSR Injection Molding as it possesses strong resistance to fuels, oils, and temperature conditions. It is highly flexible and performance superior when subjected to extreme chemicals and hence highly suited to extreme applications.In practical application, FVMQ is used very widely in the automotive fuel system, aerospace sealing, and industrial gaskets where aggressive fluid and high-temperature compatibility are required. Its reliability delivers long-term operation in harsh conditions.

|

|

| Platinum-Cured Silicone

Platinum-cured silicone is extremely well-adapted to LSR Injection Molding since it is pure, biocompatible, and heat-stable. It is non-toxic and odorless and hence excellently suitable for high-safety-demanding uses. Platinum-cured silicone is used in a wide range of medical implant applications, baby care products, and food-grade uses such as baking molds and kitchenware, where performance and cleanliness cannot be sacrificed. Its capacity for adhering to strict regulatory specifications also renders it fit for sensitive and high-grade uses.

|

| Food-grade silicone

Food-grade silicone is ideally suitable for LSR (Liquid Silicone Rubber) Injection Molding due to its non-toxic nature, heat stability, and biocompatibility and hence can be used safely in direct food contact. Flexibility and durability to withstand extreme conditions ensure reliable performance. Food-grade silicone is widely used in kitchen utensils, baby bottle teats, and baking molds in actual applications where safety, sanitation, and resistance to high heat are critical. It is well suited for medical and consumer product applications.

|

| Medical-Grade Silicone

Silicone of medical quality is especially conducive to LSR (Liquid Silicone Rubber) Injection Molding for its resistance to sterilization, biocompatibility, and plasticity, due to which it is used preferably in medical treatments. Its immunity to repeated sterilizations and continuity of performance in terms of effectiveness ensure reliability at high-risk situations. In reality, medical-quality silicone is implemented in surgical equipment, implant devices, and ventilator masks where accuracy, protection, and integrity are essential. Its compliance with rigorous medical standards ensures its use in medicine and life-saving products.

|

LSR Injection Molding Finishing Options

| Name | Description |

|---|---|

| Polishing | Polishing eliminates surface roughness, enhancing appearance and texture. |

| Texturing | Adds patterns or textures to improve grip or aesthetics. |

| Coating | Applies protective coatings like Parylene for added durability or biocompatibility. |

| Laser Engraving | EngravingtCreates precise markings or logos for identification or branding. |

| Painting | Adds color or decorative finishes for aesthetic purposes. |

| Ultrasonic Cleaning | Removes contaminants and gives high cleanliness for medical or food-grade parts. |

China LSR Injection Molding FAQ

Are You Looking for LSR Injection Molding Manufacturers in China?

Contact us for design assistance, free quotes, and expert advice today. Your inquiry will be replied to within 24 working hours, and we respect your privacy.