Metal Injection Molding Manufacturer & Supplier from China

Holly is an expert in high-precision Metal Injection Molding (MIM) services to the automotive, medical, electronics, and consumer goods sectors. Our leading-edge MIM technology extends from prototyping to mass production, with complex geometries, high tolerances (+/-0.5%), and superior material performance, making us the preferred source of high-quality metal parts.

Over two decades of production experience have taught us to specialize in machining all materials ranging from nickel alloys and stainless steel to titanium, offering custom solutions tailored specifically to your requirements. State-of-the-art facilities featuring ISO certified manufacturing processes and stringent quality controls provide parts which are long-lasting, corrosion resistant and high performance – perfect for long-term serviceability and high-performance requirements.

At Holly, we commit to affordable MIM solutions with quick turnaround and support high-volume as well as small-batch production. Contact us today for convenient MIM services tailored especially to your specifications!

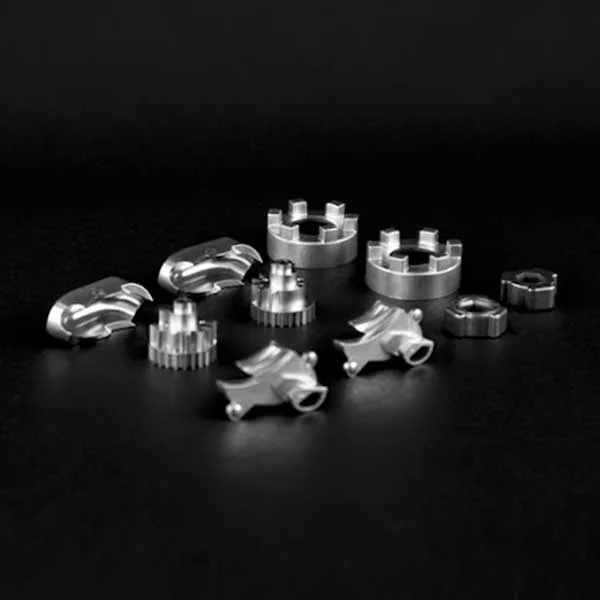

Explore Our Metal Injection Molding Products

Holly offers an extensive series of Metal Injection Molding (MIM) items to business opportunities like auto, medical, electronic, and consumer products markets. Our families of products consist of precision gears, surgical instrumentation, connectors, parts for guns, and close tolerance custom pieces. With long expertise in performance-based materials including stainless steel, titanium, and nickel alloys, we provide resilient, corrosion-representative, highly engineered items. For low-series samples or mass production, small or big in size, we offer cost-effective, high-quality MIM solutions to meet your specific needs.

Metal Injection Molding Capabilities

Metal Injection Molding Material Available

| Stainless Steel

Stainless Steel works best for Metal Injection Molding due to higher corrosion resistance, hardness, and ability to produce complex high-precision components. Its high strength and versatility entitle it to demanding applications. Stainless steel has practical applications in real-world applications in the healthcare sector with devices utilized during operations and orthodontic braces, and automotive parts such as fuel injectors and sensors. Its reliability offers dependable performance for applications requiring stringent performance requirements and critical applications.

|

|

| Titanium Alloy

Titanium Alloy is most appropriate to Metal Injection Molding since it has a high strength-to-weight ratio, corrosion resistance, and biocompatibility. Due to its ability to form light but hard components, titanium alloy has a distinct role under conditions of high performance. In actual applications, titanium alloy widely is used in aerospace materials such as turbine blades and structural components and in medical implants in the form of joint replacement and bone screws. Its consistent operation in hostile and delicate conditions is assured.

|

|

| Nickel Alloy

Nickel Alloy is especially highly suited for Metal Injection Molding due to its high high-temperature strength, corrosion resistance, and use to function under hostile conditions. Its flexibility and toughness make it acceptable for critical uses. Nickel alloy finds application in engineering applications for the aerospace industry, e.g., engine parts of a jet engine, and industry-related equipment, e.g., valves and heat exchangers, in use cases. Its reliability ensures regular performance with long-term exposure to corrosive and high-stress environments.

|

|

| Tungsten Alloy

Tungsten Alloy is most suitable for Metal Injection Molding due to its high strength, weight, and thermal shock resistance. Its ability to produce accurate heavy-duty components makes it suitable for specialty use. In actual applications, tungsten alloy is used widely in aerospace and defense technology to produce parts like counterweights and radiation shielding, and in medical devices to produce collimators for radiation therapy. Its reliability ensures operation in harsh and critical environments.

|

|

| Low Alloy Steel

Low Alloy Steel is the most suitable for Metal Injection Molding due to its cost-effective efficiency, toughness, and strength. It is possible to use it to produce high-performance long-lived and complex-shaped parts resistant to, and thus becomes an ideal material for utilization in industrial processes. Low alloy steel is extensively used in automobile components like gears and transmission components and machinery and tools components in functional applications. Its cost-effectiveness and resistance ensure broad uses in stressed and hostile environments.

|

|

| Copper

Copper makes an excellent material for Metal Injection Molding due to its superior electrical and thermal conductivity, corrosion resistance, and its ability to create complex high-precision parts. Copper’s ductility also makes it suitable for applications where efficient conduction of electricity or heat must occur. Copper, used, is pervasive in electric application such as connectors and heat sinks and industrial machinery for cooling. Its dependability offers ability in mission-critical electrical and thermal management systems.

|

|

Metal Injection Molding Finishing Options

| Name | Description |

|---|---|

| As-Sintered | Parts are used directly after sintering with no additional treatment, resulting in a rough surface. |

| Polishing | Mechanical or chemical smoothing to achieve a glossy and refined surface finish. |

| Bead Blasting | A uniform matte finish created by high-speed bead or sand particles. |

| Plating | A thin metal coating (e.g., nickel, chrome, gold) is plated on for corrosion resistance or conductivity. |

| Anodizing | An electrolytic process that produces a protective oxide film, typically with coloring potential. |

| Passivation | Chemical treatment to remove free iron and further enhance corrosion resistance. |

Metal Injection Molding Manufacturer FAQ

Are You Looking for Metal Injection Molding Manufacturers in China?

Contact us for design assistance, free quotes, and expert advice today. Your inquiry will be replied to within 24 working hours, and we respect your privacy.