China Overmolding Manufacturer & Supplier

Holly is a leading Chinese injection molding factory with experience in high-quality overmolding solutions for automotive, electronics, medical, and consumer goods sectors. With over 20 years of experience, we combine leading-edge molding technology and cost-cutting solutions to manufacture durable multi-material parts to your specifications.

Our overmolding strengths provide two-shot molding, insert molding, and single-shot overmolding with different materials like TPE, silicone, and engineering plastics. We deliver excellent adhesion, precision, and performance, complying with global regulations such as CE, RoHS, and ISO.

From prototypes to production, Holly has quick turnaround time, high-volume capacity, and strict quality checking. Join us now and make your designs into world-class functional products that perform.

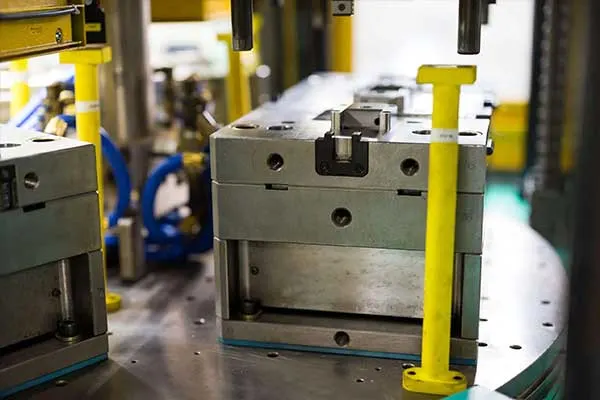

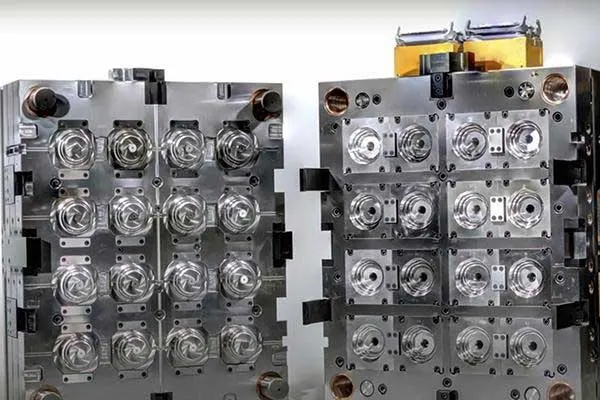

Explore Our Overmolding Molds

Holly provides overmolding machines like single-cavity machines, multi-cavity machines, family machines, and specialty machines for complex geometry. We use quality material like P20, H13, and NAK80 to construct our machines with precision and strength. We are capable of providing insert tooling, two-shot tooling, and soft-touch overmolding for use in the automotive, electronics, medical, and consumer markets. Applying leading-edge mold design and production technology, we offer cost-effective but high-performance solutions that are individually tailored to meet your demands.

Injection Molding Capabilities

Material of Overmolding Available

| ABS

ABS is a common overmolding material with good mechanical properties, impact performance, and processability. It is most commonly used as a substrate material for consumer products, automotive dashboards, and electronic enclosures. Automotive dashboards and electronic product enclosures, for example, use ABS with TPE for a soft-touch finish.

|

|

| PP

PP is light, chemical-resistant, and low-cost, hence the best option for overmolding automotive parts and household appliances. It is highly compatible with TPE and other flexible materials, fostering functionality and appearance. Some applications that use PP for good handling and abrasion resistance include trims for car interiors and seals for food packaging.

|

|

| TPE

TPE is a most suitable material for overmolding due to its ability to be hard and grippy with good grip on hard substrate such as ABS and PP. TPE is moldable, tougher, and comfortable, and it finds extensive applications in consumer electronics applications, medical device grips, and tool handles. For example, tool handle handles and phone cover cases will likely make use of the functionality of TPE as they are soft to touch and even possess the ability to absorb shocks.

|

|

| Silicone

Silicone is superior in overmolding since it is more heat-resistant, flexible, and biocompatible. Silicone adheres well to plastics and metals and is ideal for hospital equipment, cookware, and car gaskets. Medical tubing and seals with high temperature use silicone in the majority of situations since the silicon is reliable under extreme conditions.

|

| TPU

TPU is a better overmolding alternative due to its excellent abrasion resistance, elasticity, and resistance to chemicals. It demonstrates favorable adhesion on materials like PC and ABS and thus, a longer service life. TPU is utilized to a wide range of cases, cables, and industrial components for protection. Phone cases that last long, as well as cable connectors, mostly utilize TPU due to its durability and flexibility.

|

|

| PC

PC is very resistant to strength, transparency, and impact, making it a suitable candidate for overmolding in electronic enclosures and automotive components. Its ability to bond with TPE and silicone increases the durability of products. For example, transparent electronic shields and automotive light housings are likely to use PC because of its transparency and strength.

|

|

Overmolding Finishing Options

| Name | Description |

|---|---|

| Polishing | Removes surface roughness, enhances gloss and texture, ideal for high-appearance parts. |

| Sandblasting | Blows high-speed sand particles to create a uniform matte finish, which promotes adhesion and slip resistance. |

| Texturing | Creates patterns or textures on the mold surface for slip resistance, decoration, or hiding parting lines. |

| Painting/Coating | Applies color or protective coatings for weather resistance, chemical resistance, or custom decoration. |

| Plating | Electroplates metal layers (e.g., chrome, nickel) for enhanced wear resistance, conductivity, or decoration. |

| Laser Etching | Uses laser to engrave text, designs, or logos with precision and longevity. |

China Overmolding FAQ

Are You Looking for Overmolding Mold Manufacturers in China?

Contact us for design assistance, free quotes, and expert advice today. Your inquiry will be replied to within 24 working hours, and we respect your privacy.