We believe you would wish to purchase your medical device components from the best and most accurate ThomasNet CNC machining companies. It is therefore essential to understand where ThomasNet manufacturers excel in precision machining for the medical industry. We here address the top 10 best ThomasNet CNC machining medical device manufacturers, areas of expertise, manufacturing capability, and focus on quality to provide safe and working medical parts.

1. List of CNC Machining Companies for Medical Devices on ThomasNet

Below is the top 10 of CNC machining firms on ThomasNet providing precision manufacturing services for medical devices. They are renowned for having technical capabilities, state-of-the-art facilities, and a commitment to the supply of high-quality medical parts.

| NO. | Company | Website | Year Established |

| 1 | Holly Plastic | https://www.hollyplasticparts.com/ | 2000 |

| 2 | Janco Medical | https://janco-medical.com/ | 1963 |

| 3 | LA CNC Inc | https://lacncmachineshop.com/ | 2019 |

| 4 | Roncelli Plastics | https://roncelli.com/ | 1969 |

| 5 | Sinopac Group | https://sinopacgroup.com/ | 2001 |

| 6 | Eagle Instruments | http://www.eagleinstrumentsinc.com/ | 1969 |

| 7 | Roberts Swiss | https://www.rswiss.com/ | 1953 |

| 8 | Fisher Barton | https://www.fisherbarton.com/ | 1973 |

| 9 | Unity Tool | https://unityprecisionmfg.com/ | 1969 |

| 10 | VO-Tech | https://vo-tech.net/ | 1996 |

2. Top 10 CNC Machining Companies for Medical Devices on ThomasNet

Here is a comprehensive list of the best CNC machining companies on ThomasNet, producing highly accurate components utilized in medical equipment. The company overviews all possess manufacturing capacity, technical personnel, and customer-oriented services.

Top 1: Holly Plastic

Holly Plastic is a 2000-established company and is one of the most experienced Chinese rapid prototyping services, plastic injection tooling, and CNC machining factories. It is based in Jiaxing, Zhejiang Province. It provides global customers with medical devices, automobiles, electronics, and industrial equipment. Holly Plastic stands out as a special company that is well-known for producing extremely high-precision parts with high tolerances, which fall under the stringent quality demands of the medical field.

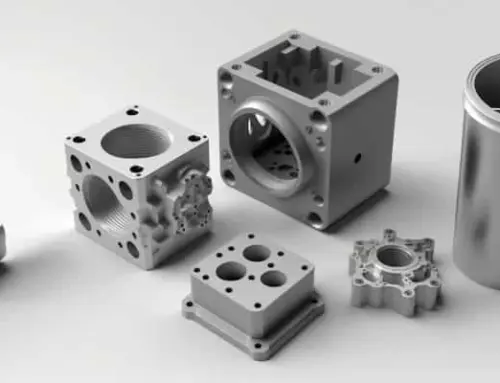

The company excels in 3-axis, 4-axis, and 5-axis CNC turning, drilling, milling, and EDM machining to deliver complex geometries and accurate components. Holly Plastic also machines other engineering plastics such as PEEK, PC, ABS, and PPSU to make them biocompatible and robust enough for implantation within medical devices. Other services provided are the vacuum casting, rapid prototyping, and assembly, which provide the complete product development process and provide the medical device manufacturers with an accelerated time-to-market.

Quality is uppermost in the minds of the individuals at Holly Plastic, which is ISO 9001:2015 certified and enhanced with new inspection equipment. Holly Plastic has successfully teamed with several OEMs to manufacture surgical instrument components, diagnostic devices, and implantable medical devices. With technical know-how and customer orientation, Holly Plastic is a reliable partner for high-precision medical device components.

Website: https://www.hollyplasticparts.com/solution/medical-plastic-injection-molding/

Year established: 2000

Location: China

Products:

- CNC Machined Components

- Plastic Injection Molding

- Rapid Prototyping (3D Printing, Vacuum Casting)

- Medical Device Components

- Automotive and Electronics Parts

Top 2: Janco Medical

Janco Medical, of Rollinsford, New Hampshire, and established in 1963, is an American contract manufacturer of precision CNC machining, medical device assembly, and cleanroom manufacturing. The company has manufactured precise parts for medical devices, diagnostic, and healthcare firms for over four decades. All parts are inspected for precision and regulation compliance by Janco Medical, thus ensuring the parts to precise ISO and FDA standards.

It employs 3-axis and 4-axis CNC turning, milling, and drilling to make complex and high-tolerance parts. Janco Medical produces metal, polymers, and plastic composites that are used mostly in medical devices and runs prototype and production orders. It offers cleanroom assembly, RF sealing, compression molding, and thermoforming and delivers ready-to-use componentry and services from the entire product development cycle to its customer.

Janco Medical guarantees quality assurance by its ISO 13485 certificate and FDA registration and abides by medical standards in the most rigorous manner possible. They have been long-time providers of surgical instrument parts, diagnostic, and disposable medical device components to OEMs for more than a decade. They are the fastest-growing medical device company partner globally because of their technical support, world-class facilities, and customer service.

Website: https://janco-medical.com/

Year established: 1963

Location: USA

Products:

- CNC Machined Components

- Medical Device Assembly

- Thermoformed Components

- Compression Molded Parts

- RF Sealed Products

Top 3: LA CNC Inc

LA CNC Inc is a California-based Los Angeles company incorporated in 2019. It is a precision CNC machining firm with experience in producing high-tolerance medical device components. LA CNC Inc is an emerging firm that has become one of the best manufacturers of high-quality, durable parts for medical device, diagnostic, and surgical device firms. Its focus on the latest in machining and quality control processes enables it to meet the strict medical-grade requirements.

The company offers 3-axis and 5-axis CNC turning, milling, drilling, and finishing, and is capable of manufacturing geometrically complex and high-tolerance parts. LA CNC Inc. offers metal machining, engineering plastic, and composite materials and prototyping, small-batch manufacturing, and high-volume production. Assembly, polishing, and surface treatment are a few of the services that can be offered to clients in order to provide finished-to-use parts for use in medical devices. Their rapid turnaround and speed minimize time-to-market for new product families.

LA CNC Inc boasts strict quality control with ISO 9001 certification and in-process inspection systems. They were able to service several OEMs, producing components for surgical instrumentation, diagnostic equipment, and implantable devices. Its commitment to technical excellence, accuracy, and customer service makes it a partner of preference for medical device companies.

Website: https://lacncmachineshop.com/

Year established: 2019

Location: USA

Products:

- CNC-Machined Medical Components

- Surgical Instrument Parts

- Diagnostic Device Housings

- Prototype and Production Runs

- Surface-Treated Components

Top 4: Roncelli Plastics

Roncelli Plastics, established in 1969, of Monrovia, California, is a family-based business dealing in precision plastic parts and CNC turning of medical device parts. Roncelli Plastics has global medical, aerospace, semiconductor, and industrial clients for whom it supplies quality parts to satisfy strict regulatory standards. Roncelli Plastics has evolved as a company with the latest manufacturing technology combined with superior customer service.

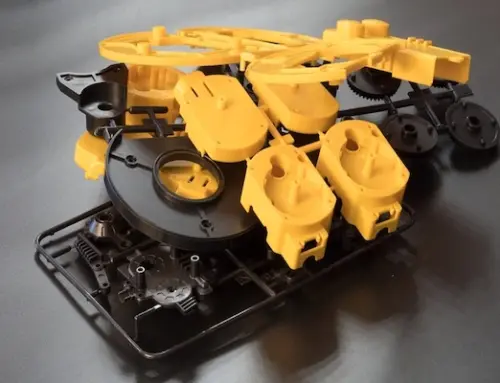

Their 4-axis CNC machining is turning, milling, and accurate drilling to produce intricate plastic and composite components with tight tolerances. Roncelli Plastics machines a broad range of engineering plastics like PC, ABS, PEEK, and PPSU with metal insertions where appropriate. Roncelli Plastics offers injection molding, die cutting, 3D printing, and assembly so that customers can buy finished, ready-to-assemble parts to incorporate into medical devices.

Quality is the concern of an ISO 9001-certified company, and strict process auditing. Roncelli Plastics has cooperated successfully with OEMs for the production of surgical instruments, diagnostic housings, and implantable medical components. Its high-volume manufacturing, high-end technical capability, and customer satisfaction orientation make it the first choice among the medical device manufacturers for precision-engineered solutions.

Website: https://roncelli.com/

Year established: 1969

Location: USA

Products:

- Precision CNC Plastic Components

- Injection Molded Parts

- 3D Printed Prototypes

- Die-Cut Components

- Assembled Medical Device Parts

Top 5: Sinopac Group

Sinopac Group, founded in 2001 in Rancho Cucamonga, California, is a diversified manufacturer and sourcing organization providing precision CNC-machined and tolerance components utilized for medical devices. It provides highly complex components to OEMs using cutting-edge technology and uncompromising knowledge of materials to provide stringent specifications for medicine and industry.

Sinopac Group offers the complete range of services from 3-axis and 5-axis CNC turning, milling, casting, molding, stamping, bending, bonding, to heat treatment. Sinopac Group processes metals, plastics, and composite materials to produce products and build production and prototype runs. Sinopac Group offers supply chain management, assembly, and quality assurance, and offers turnkey solutions that eliminate complexity in manufacturing medical devices and preserve customers’ time-to-market.

Sinopac Group is at the international standard quality level with ISO certifications and rigorous inspection processes. Sinopac Group has been providing surgical instrument parts, diagnostic device parts, and other critical medical device parts year by year. With technical sophistication, full-line capability, and precision attention, Sinopac Group is the best business partner for medical device firms in the world.

Website: https://sinopacgroup.com/

Year established: 2001

Location: USA

Products:

- Precision CNC-Machined Parts

- Cast and Molded Components

- Stamped and Bent Metal Parts

- Bonded and Heat-Treated Components

- Medical Device Assemblies

Top 6: Eagle Instruments

Eagle Instruments, established in 1969 in Farmington Hills, Michigan, is a precision CNC-machined and assembled US medical devices company. With more than four decades of history in the manufacturing of high-tolerance medical equipment parts, surgical tools, and health equipment parts, it has been a consistent producer of quality medical products. Its commitment to precision, dependability, and strict compliance with medical standards made it a partner of choice within its industry that could always be relied on.

Eagle Instruments offers premium CNC turning, milling, drilling, and grinding to produce precision metal, plastic, and composite parts. Eagle Instruments also offers assembly, test, and finish to deliver ready-to-install medical device parts. Their engineers closely collaborate with customers to optimize part design, manufacturability, and reduce prototype-to-production lead times to accommodate small-batch as well as large-volume production runs.

Eagle Instruments is ISO 9001 registered and has rigorous quality control in the production process. They have been able to supply various OEMs with surgical device components, diagnostic box components, and implantable device components. They deliver medical device components promptly to the customer with quality through technical expertise, modern equipment, and customer-centric service.

Website: http://www.eagleinstrumentsinc.com/

Year established: 1969

Location: USA

Products:

- CNC-Machined Components

- Surgical Instrument Parts

- Diagnostic Device Housings

- Prototype and Production Runs

Top 7: Roberts Swiss

Roberts Swiss, founded in 1953 and operating in Easton, Pennsylvania, is a major manufacturer of precision CNC Swiss turned and machined medical device components for the industry. Roberts Swiss has been supplying OEMs of implantable, diagnostic, and surgical medical devices for more than a decade. Roberts Swiss possesses a proven history of manufacturing small-diameter precision medical components with tight tolerances that control medical device performance.

The company is a specialist in Swiss-style CNC turning, multi-axis machining, and micro-machining of plastic and metal engineering materials. Roberts Swiss is capable of machining titanium, stainless steel, aluminum, and other polymers and sending out prototypes and high-volume production components. The company provides secondary operations like assembly, inspection, and finishing of ready-to-ship and fully compliant medical components.

Roberts Swiss is ISO 13485 and ISO 9001 certified and is compliant and of high quality. Roberts Swiss manufactures cardiovascular device components, orthopedic device components, and diagnostic medical device components with the highest precision. Technical know-how, advanced machinery, and customer care make Roberts Swiss the best partner medical device manufacturers can rely upon whenever they require micro-precision components.

Website: https://www.rswiss.com/

Year established: 1953

Location: USA

Products:

- Swiss-Turned Components

- Multi-Axis Machined Parts

- Micro-Precision Medical Parts

- Assembly and Inspection Services

- Implantable Device Components

Top 8: Fisher Barton

Fisher Barton, a company based in Fort Smith, Arkansas, and established in 1973, is a US precision CNC machining business with a history in fabricating intricate medical device component pieces. It provides contract manufacturing to medical equipment producers, diagnostic equipment producers, and surgical equipment manufacturers on a quality, precision, and compliant regulatory basis.

Fisher Barton delivers 3-axis, 4-axis, and 5-axis metal turning, milling, drilling, and grinding, and plastic engineering machining. Finalized materials range from stainless steel and titanium to aluminum and polymers, and part manufacturing on a high tolerance for use in medical devices. Assembly, finishing, and inspection rooms can be offered to maintain parts to ISO 13485 and FDA standards for application in the medical field.

Fisher Barton’s commitment to quality is also assured with ISO-certified state-of-the-art inspection tools and techniques. They have been serving some OEMs in producing highly accurate components for surgical instruments, diagnostic equipment, and implantable devices. With its technical knowledge, manufacturing facilities, and customer-focused services, Fisher Barton is a reliable partner in medical device production.

Website: https://www.fisherbarton.com/

Year established: 1973

Location: USA

Products:

- CNC-Machined Medical Components

- Surgical Instrument Parts

- Diagnostic Device Housings

- Prototype and Production Runs

- Assembly and Inspection Services

Top 9: Unity Tool

Unity Tool, of Grand Rapids, Michigan, and founded in 1969, is a precision CNC machining and injection mold firm with experience in the business of providing component services for medical devices. Unity Tool has some background in producing high-precision, close-tolerance components of high quality for implantable, diagnostic, and surgical devices that are sold to healthcare OEMs.

Unity Tool has high-end CNC turning, milling, and multi-axis metal and engineering plastic machining, including injection molding of polymer parts. Prototype, low-volume, and full-production parts are available. Assembly, finishing, and inspection are also available, so medical parts will be ISO and FDA compliant.

Unity Tool is ISO 13485-certified and has strict quality control measures in manufacturing. They have been able to deliver medical components for surgical equipment, diagnostic cases, and implantable medical devices. Their technical capability, full-spectrum capability, and customer satisfaction commitment are among the factors that make Unity Tool a great partner in complex medical device manufacturing.

Website: https://unityprecisionmfg.com/

Year established: 1969

Location: USA

Products:

- CNC-Machined Components

- Injection Molded Medical Parts

- Prototype and Production Runs

- Surgical and Diagnostic Device Components

Top 10: VO-Tech

VO-Tech, based in Ontario, California, was established in 1996 as a computer-numerical control plant specializing in the high-tolerance parts of medical equipment. It is a high-tolerance expert manufacturing infinitesimally minute-in-scope parts for health care facilities, diagnosis, and surgery, with the promise of delivering to strict medical industry standards.

VO-Tech offers 3-axis, 4-axis, and 5-axis CNC turning, milling, and metal, plastic, and composite part drilling. They offer prototyping, small runs, and high-volume production. They offer assembly, finishing, and inspection, and ready-to-assemble parts for shipping to medical device manufacturers.

VO-Tech follows quality and regulatory compliance with ISO 13485 certification and in-process inspection. VO-Tech has been able to operate well with a massive majority of OEMs in providing components for surgical devices, diagnostic devices, and implantable devices. VO-Tech’s current technology, technical expertise, and customer-centric approach make it a dependable partner in manufacturing medical devices.

Website: https://vo-tech.net/

Year established: 1996

Location: USA

Products:

- CNC-Machined Medical Components

- Surgical Instrument Parts

- Diagnostic Device Housings

- Prototype and Production Runs

- Assembly and Inspection Services

3. Tips to Choose CNC Machining Companies for Medical Devices on ThomasNet

The selection of a suitable CNC machining firm for the components of medical devices is crucial for obtaining accuracy, reliability, and conformity.

First, consider the experience and history of the company in the healthcare industry. High tolerance levels and compliance with FDA and ISO regulations are required for medical devices, making it very important that the company has a history of successfully putting into practice in the healthcare industry. Mature organizations will certainly have established procedures and quality systems for risk mitigation during manufacturing.

Second, look at technical capabilities and facilities. Look at firms that have multi-axis CNC turning, machining, and milling capability, and the ability to machine on a variety of materials like metals, polymers, and composites. High technology equipment, prototyping, assembly, and finish capability enable your parts to be made to specification and affordably for volume or small-batch manufacture.

Third, check quality assurance and certification. ISO 13485 and ISO 9001 certification and FDA registration are regulatory and quality indicators of a company’s commitment. Additionally, inquire regarding inspection processes, in-process monitoring, and traceability systems to ensure component reliability.

Finally, add project management and customer service. A sound communication, design optimization, and engineering consultancy equilibrium manufacturer can be an excellent lead reduction time resource and quicker product output. With a diplomatic equilibrium on ThomasNet, you are able to select a CNC machining vendor who will provide precise and quality medical device components.

4. Conclusion

Overall, medical devices are a high-precision and reliability-oriented industry, and ThomasNet has numerous CNC machining companies with full capacity and service. The following are the top 10 highest-ranked CNC machining companies that can produce high-precision, high-accuracy components to close up to medical tolerances and enable manufacturers to bring their products to market on time.

Leave A Comment