Do you want to know about the top 3D printing suppliers in the USA to turn your ground-breaking ideas into reality? America is the cradle of additive manufacturing, and some highly innovative and established 3D printing suppliers are home-based here. Ranging from aerospace, medical, automotive, and consumer products, the fields are diverse, and the suppliers offer innovative services for different industry demands. Let us have a close look at a detailed analysis of the USA’s top 10 3D printing service bureaus, their respective forte, technologies, and what makes them stand out in a competitive business environment.

1. List of 3D Printing Services in the USA

The following is the list of the top 3D printing service bureaus in the USA, their official websites, and the year they were founded, together with a brief background description of each company.

| NO. | Company | Website | Year Established |

| 1 | Holly Plastic Parts | https://www.hollyplasticparts.com/ | 2000 |

| 2 | Shapeways | https://www.shapeways.com/ | 2007 |

| 3 | Markforged Holding Corporation | https://markforged.com/ | 2013 |

| 4 | Xometry | https://www.xometry.com/ | 2013 |

| 5 | Formlabs | https://formlabs.com/ | 2011 |

| 6 | Carbon | https://www.carbon3d.com/ | 2013 |

| 7 | MatterHackers | https://www.matterhackers.com/ | 2012 |

| 8 | Desktop Metal | https://www.desktopmetal.com/ | 2015 |

| 9 | Velo 3D | https://velo3d.com/ | 2014 |

| 10 | re:3D | https://re3d.org/ | 2013 |

2. Top 10 3D Printing Services in the USA

Resuming the number of top 3D printing services in the USA, it is essential to establish what makes each of these companies unique and why the choice of an American-based firm would be revolutionary for a project or business.

Top 1: Holly Plastic Parts

Holly Plastic Parts is a China-based 3D printing service bureau with a heritage dating back to 2000 that provides accurate plastic parts for prototyping and low- to medium-volume production. Having more than twenty years of experience in plastics production, the firm has taken up the quest of high-resolution 3D printing, i.e., producing low-volume as well as intricate geometries. Holly possesses the newest FDM and SLA printers and a wide variety of engineering-grade thermoplastics that are durable, thereby positioning itself well to do business in the automotive, medical, and consumer electronics industries.

The business boasts quick turnaround time, in-house tooling support, and rigorous quality control, all to ISO standards. Its design-through-delivery model offers customers reduced cycle time cost, including design consultation, material suggestions, and finishing like painting, and assembly. Holly Plastic Parts has offered its custom enclosures and functional prototypes to various start-ups in medical and robotics companies. Its customization possibilities, combined with production continuity, qualify it as a sound partner business for firms requiring quick, precise, and dependable 3D-printed components.

Website: https://www.hollyplasticparts.com/3d-printing/

Year established: 2000

Location: China

Products:

- FDM 3D printed parts

- SLA prototypes

- CNC-machined plastic parts

- Custom molded enclosures

Top 2: Shapeways

Shapeways, founded in 2007, is among America’s leading on-demand 3D printing service brands. Based in New York, Shapeways offers digital manufacturing services to customers worldwide via its cloud-based platform and industrial printers. Shapeways offers over 90 materials and finishes, including nylon, resin, metal, and multi-color sandstone, to facilitate high-quality production of prototypes and end-use parts.

Shapeways stands out with auto-quote, e-commerce-enabled feature, and mass producible scalability from one to a thousand. It is therefore a platform of choice for designers, engineers, and entrepreneurs for agility without compromising on quality. It caters to industries ranging from architecture and healthcare to fashion and robotics. Its clientele benefits from professional support, DfAM consulting, as well as hassle-free logistics. Having shipped millions of printed items worldwide, Shapeways has been at the forefront of making industrial-level 3D printing technology accessible to businesses of any size and type.

Website: https://www.shapeways.com/

Year established: 2007

Location: USA

Products:

- Nylon 3D printed parts

- Full-color sandstone prints

- Metal additive components

- Rapid prototyping services

Top 3: Markforged Holding Corporation

Markforged Holding Corporation, founded in Massachusetts in 2013, is an industrial-grade solutions and hardware 3D printing company. Markforged is perhaps best known for producing composite materials and metal, including its Continuous Fiber Reinforcement (CFR) technology. Markforged cloud-enabled printers 3D print parts with equivalent strength to machined aluminum but with worldwide applications in functional prototypes, end-use manufacturing, and tooling.

What makes Markforged stand out is that it has an end-to-end integrated platform that consists of cutting-edge hardware, Eiger software, and a portfolio of patented materials like Onyx, carbon fiber, and stainless steel. Their Digital Forge platform contains remote monitoring, fleet management, and version control capability, all of which are designed with industrial scalability in mind. Markforged has printed parts for Fortune 500 manufacturers, aerospace subcontractors, and precision manufacturers that rely on robust, engineering-grade parts. Committed to a mission of reliability and automation, Markforged is assisting customers in getting high-strength parts to market more quickly with lower cost and supply chain reliance.

Website: https://markforged.com/

Year established: 2013

Location: USA

Products:

- CFR composite parts

- Metal 3D printed components

- Onyx and carbon fiber prints

- Cloud-based 3D printing software

Top 4: Xometry

Xometry was established in 2013 and is currently one of the largest digital manufacturing platforms in the US. Maryland-based Xometry provides end-to-end on-demand solutions in sheet metal fabrication, injection molding, CNC machining, and 3D printing. Xometry makes use of different technologies in 3D printing, such as FDM, SLA, SLS, DMLS, and PolyJet. Xometry can process engineering-grade materials that can be utilized for production and prototyping.

The USP at Xometry is the AI-powered real-time quoting engine that enables ordering and reduces lead times. The engine enables the customer to upload 3D models, enter requirements, and receive exact quotes in real time. The company has an astronomically huge network of more than 10,000 pre-vetted partners from all over the world that not only renders it scalable but also ensures quality consistency. Xometry manufactures a wide range of aerospace, medical, defense, and robotics products. Its technical prowess and turnaround time are relied upon by the likes of NASA and General Electric. With wide U.S.-based manufacturing capabilities and global logistics, Xometry is one-stop shopping for organizations needing high-precision parts in volume.

Website: https://www.xometry.com/

Year established: 2013

Location: USA

Products:

- SLA/SLS 3D printed parts

- FDM and PolyJet models

- DMLS metal components

- On-demand rapid prototyping

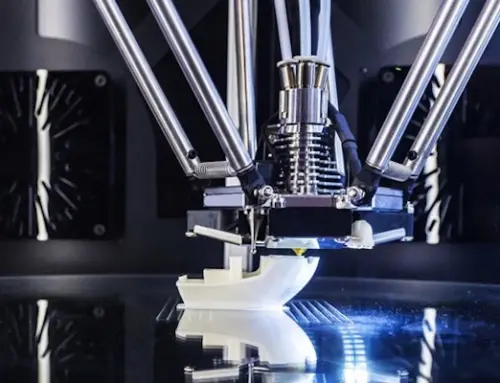

Top 5: Formlabs

Massachusetts-based Formlabs, a startup in 2011, is a worldwide professional desktop 3D printing industry leader. Formlabs is a specialist in SLA and SLS technology and is introducing revolutionary additive manufacturing capability to engineers, designers, and medical professionals. Its Red Dot Design Award-winning Form 3+ and Fuse 1+ systems are utilized everywhere across the globe to 3D print high-resolution prototype models, medical implants, and end-use production parts to industrial tolerances.

With more than 120,000 printers sold worldwide, Formlabs has an end-to-end solution with PreForm software, post-processing hardware, and more than 30 specialty materials. Its materials range from general-purpose, tough, flexible, biocompatible, and castable resins that are used in dental, jewelry, consumer products, and automotive applications. The firm’s emphasis on usability, repeatable precision, and continuous material development has seen it become a de facto partner of choice by the likes of Google, Gillette, New Balance, and the Mayo Clinic. Carbon’s scalable technology allows users to iterate quickly, design with tight tolerances, and move seamlessly from design to production, directly from their facility.

Website: https://formlabs.com/

Year established: 2011

Location: USA

Products:

- SLA 3D printed parts

- SLS nylon components

- Biocompatible dental prints

- Engineering resins and powders

Top 6: Carbon

Carbon, which was established in Redwood City, California, in 2013, revolutionized additive manufacturing with its innovative, patented Digital Light Synthesis™ (DLS) technology. Carbon’s technology, in contrast to traditional 3D printing, uses digital light projection and oxygen-permeable optics to produce functional, isotropic parts straight from resin. Carbon 3D printers, including the M3 and L1, feature improved print speeds and production quality levels, making digital manufacturing possible.

Carbon has collaborated with international brands such as Adidas, Ford, and Riddell. Carbon’s capacity to create high-volume components with bespoke geometries was highlighted through collaborations with Adidas for 4D midsoles. Carbon also provides enterprise-level design iteration software, lattice software, and production workflow software. With its precision-engineered range of high-performance materials, such as elastomers, rigid polyurethanes, and dental resins, Carbon is addressing industries from footwear and automotive to healthcare and consumer products. Its focus on speed, scale, and repeatability makes it the go-to choice for companies transitioning from prototype to full production with 3D printing.

Website: https://www.carbon3d.com/

Year established: 2013

Location: USA

Products:

- DLS 3D printed parts

- Custom lattice structures

- RPU and EPU components

- Dental and medical-grade prints

Top 7: MatterHackers

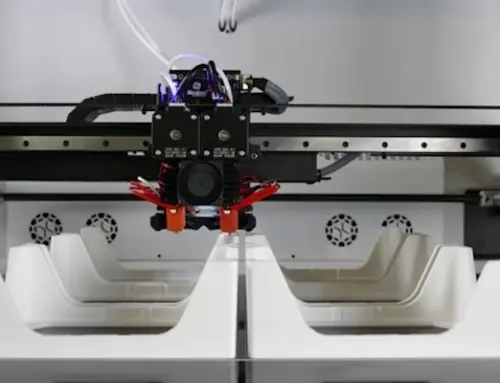

In 2012, MatterHackers was founded in California as a USA industry-leading online retailer and 3D printing solutions provider. It distributes an amazing array of desktop 3D printers, filaments, resins, and accessories, and specialty print services for educational, engineering, hobbyist, and industrial use. Employing over 70 staff with an amazing array of 2,000+ in-stock products, MatterHackers is a market and technical leader among additive manufacturing professionals and hobbyists.

What sets MatterHackers apart is its highly technical customer service, personalized recommendations, and coast-to-coast coverage. Its in-house engineers walk customers through machine calibration setup, material selection, and design settings to enable them to achieve successful prints. It supports FDM and SLA technologies and represents brands including Ultimaker, Raise3D, Prusa, and BCN3D. MatterHackers also provides training workshops, print farms, and supply management services to business clients. The company’s products have been employed by NASA engineers, K-12 teachers, and low-production manufacturers who wish for simple, inexpensive 3D printing technologies. From newcomers to running a design lab, MatterHackers provides both resources and know-how to get your concepts airborne.

Website: https://www.matterhackers.com/

Year established: 2012

Location: USA

Products:

- FDM 3D printing services

- SLA resin printing

- Custom filament supply

- Professional training and support

Top 8: Desktop Metal

Desktop Metal, a Boston-region startup in Burlington, was formed in 2015. Desktop Metal is fast becoming a metal 3D printing giant with an aim of creating best-of-breed products in the aerospace, automotive, medical, and consumer products segments. Its end-game objective is to lower metal additive manufacturing cost and speed to levels akin to mass production. Desktop Metal equipment is based on two main systems: the Studio System™ for office-based 3D printing of metal, and the Production System™ for shop-floor volume 3D printing.

BMD technology from Desktop Metal is proprietary technology that enables direct production of high-quality, highly dense metal parts without interrupting active legacy CNC machining or injection molding. It also provides post-processing and sintering in a bid to provide end-to-end capability. Customers of Desktop Metal, like Ford, BMW, and the US Army, have incorporated Desktop Metal solutions into their manufacturing in order to meet the needs for attaining reduced lead time and greater design freedom. Desktop Metal provides metal material expertise through the help of various alloys like stainless steel, titanium, and aluminum in a bid to serve various industries.

Website: https://www.desktopmetal.com/

Year established: 2015

Location: USA

Products:

- Studio System™ metal 3D printing

- Metal sintering and post-processing

- Stainless steel, titanium, and aluminum alloys

Top 9: Velo 3D

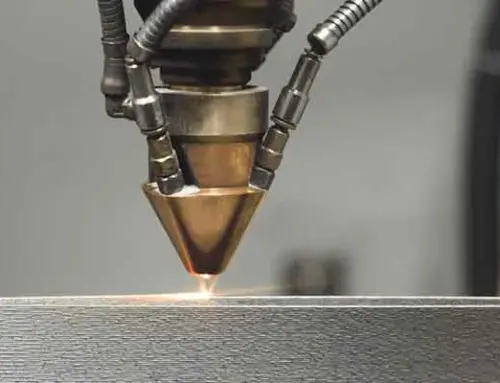

Campbell, a California-based startup founded in 2014, is revolutionizing the metal 3D printing industry with its technology and high-value solutions for aerospace, energy, and automotive industries. Its Sapphire printer boasts a patented LPBF process of laser powder bed fusion, which produces highly complex geometries that are not possible with traditional manufacturing techniques. With SupportFree™, Velo 3D eliminates support structures and prints with post-processing parts very low.

Velo 3D has been said to print parts with mechanical integrity and surface finish, even in such challenging-to-machine materials as titanium, Inconel, and aluminum. Velo 3D’s biggest clients are Lockheed Martin, Honeywell, and Boeing and supplies them with advanced manufacturing solutions for mission-critical components. It is less expensive, faster to produce, and allows them to design innovations previously out of reach to implement Velo 3D technology on their production lines. Businesses can manufacture complex components on a large scale using Velo 3D technology and advanced materials.

Website: https://velo3d.com/

Year established: 2014

Location: USA

Products:

- Sapphire® metal 3D printing system

- SupportFree™ technology

- Inconel, titanium, and aluminum alloys

- Design optimization software

Top 10: re:3D

re:3D, founded in 2013 and based in Houston, Texas, is a groundbreaking 3D printing company that manufactures large-format, environmentally friendly additive manufacturing systems. The company’s flagship product, the Gigabot 3D printer, has been touted for 3D printing big parts with record resolution and is aimed at industries such as manufacturing, education, robotics, and others. re:3D is working to enable 3D printing to be affordable and accessible, and provide open-source, editable systems that aim at a wide range of companies and institutions.

The company is also extremely committed to being sustainable, and the 3D printing is accomplished with recycled material and green manufacturing support. re:3D has been a leader in minimizing waste and saving customers money while still being environmentally conscious. re:3D customers are schools, small businesses, and large organizations, which are all accommodated by the company’s capacity for printing large working pieces with very minimal negative impact on the planet. Through its advanced technology and sustainability initiatives, re:3D is transforming the landscape of large-format 3D printing capabilities so that industries can embrace new solutions without needing to compromise on anything in the interest of sustainability.

Website: https://re3d.org/

Year established: 2013

Location: USA

Products:

- Gigabot® 3D printers

- Custom 3D printing solutions

- Recycled filament

- Large-format prototypes

3. Advantages of Using American 3D Printing Service

There are several points in favor of using an American 3D printing service, making it a preferable choice for individuals and businesses.

One of the greatest benefits is access to high levels of innovation and technology. World-class 3D printing companies are found in the United States with easy access to new production techniques, quality materials, and new technology. This allows customers to get quality and replicable prints of precise specifications.

The second major advantage is the high level of intellectual property (IP) protection in the country. The US boasts among the most stringent IP legislation globally, i.e., your designs and products are well-protected. This will be handy for companies selling proprietary designs or producing products, since it will discourage people from stealing or borrowing your IP.

Thirdly, American-based 3D printing companies are best known for providing the best technical expertise, accompanied by customer service. The majority of the America-based companies provide one-to-one consultancy services, design assistance, and post-production assistance to help customers get the best out of their designs. Quality service saves companies time and costly errors in production.

Finally, an American 3D printing service is eco-friendly. The majority of U.S. businesses have a policy of recycling and green business, so they have a zero carbon footprint during the production process.

Overall, an American-based 3D printing service offers the best quality, safety, speed, and support, and it is the smart choice for the majority of businesses.

4. Conclusion

Following is the revised list of 3D printing services that we have compiled for the year 2025. America is also among the world leaders in 3D printing, and American companies are at the forefront of innovation and technology. If you need first-rate prototyping or mass production, or you need printing technology that is friendly to the environment, you can obtain the best service at minimum expense. The range of 3D printing services that American companies offer ensures that there is always a precise fit for every company within every industry.

Leave A Comment