How accurate is 3D printing? It depends on several factors, including the type of technology, quality, materials, and complexity of the model of the printer, the practicality of the design, and user-defined printing parameters.

Because 3D printers rely on countless moving parts and materials, this process will never produce 100% accurate parts. (Neither will any production process.) However, additive manufacturing users can take steps to improve the accuracy of the printing process and ultimately produce better 3D printed parts.

This article will look at the dimensional accuracy of 3D printed parts, the accuracy differences between different technologies, and how users can make their parts more accurate.

1. What is Dimensional Accuracy?

The dimensional accuracy of 3D printing is one of the most common questions asked, but it is often confused with other important concepts like resolution, precision, and tolerance.

In short, a precisely sized part is a part that matches the size and form of the original design. Therefore, accuracy is a measurement of how close the printed part is to the digital version. This measurement is usually expressed in percentages or millimetres, such as ±1% or ±0.5 mm.

The term accuracy is sometimes used interchangeably with tolerance, which is the allowable deviation between the actual size of the workpiece and the expected size.

However, please note that tolerances are also user-defined values: the customer will specify an acceptable tolerance to the manufacturer based on the importance of certain characteristics and dimensions.

Precision is different from a resolution. Resolution refers to the pixel size of the SLA 3D printer. It is also different from precision, which focuses on the reliability and repeatability of 3D printers, as well as the ability to continuously manufacture the same object.

2. Accuracy of different 3D printing technologies

Not all 3D printing technologies are the same in terms of the accuracy of the printed parts. Although other factors will produce further changes, the type of additive manufacturing technology has a great influence on the accuracy of the parts.

FDM

Fused deposition modeling in polymer extrusion 3D printing technology is more accurate and is most commonly used for prototypes. In desktop format, it is the most affordable 3D printing technology, although it is also used in professional and even industrial environments.

- The accuracy of a desktop FDM 3D printer is around ±0.5 mm.

- The accuracy of industrial FDM printers is around ±0.2 mm.

Resin

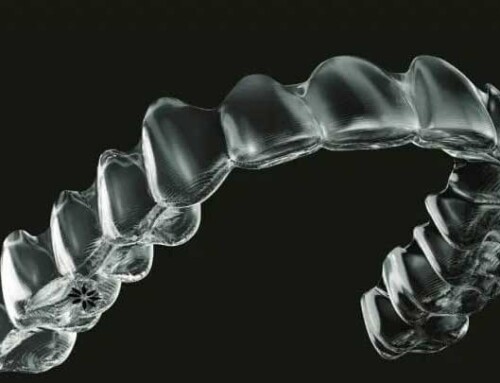

Photopolymer printing technologies like SLA and DLP use light sources such as lasers or projectors to cure photosensitive resins. These highly accurate technologies are used by individuals and professionals, and some machines cost no more than FDM.

- The accuracy of the desktop resin 3D printer is about ±0.1 mm.

- The accuracy of professional resin 3D printers is around ±0.01 mm.

SLS

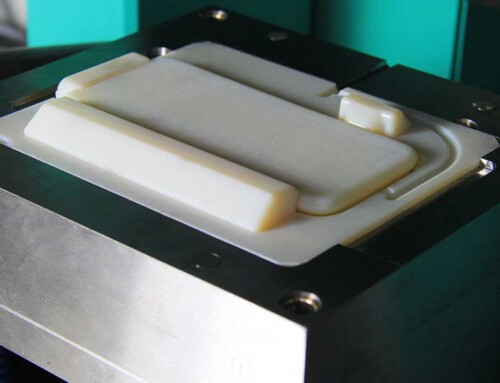

Selective laser sintering is a 3D printing technique that uses a laser to sinter powder particles, usually nylon. SLS printers are accurate, although their main selling point is the ability to make complex geometric figures because they do not require printing support structures.

- The accuracy of the SLS 3D printer is around ±0.3 mm.

Powder bed fusion

Metal powder melting process, such as SLM using laser to melt or sinter metal powder particles. This technology is precise and there is no consumer-level version. However, metal additive manufacturing usually requires a lot of post-processing.

- The accuracy of the powder bed fusion 3D printer is about ±0.1 mm.

Material jet

Although not as common as similar technologies, the 3D printing process of material jetting is highly accurate because it does not require heating, which can cause warping and other deformations.

- The accuracy of the spraying 3D printer is about ±0.05 mm.

3. Other Factors Affecting Dimensional Accuracy

The type of 3D printing technology is not the only factor that determines the dimensional accuracy of 3D printing. Materials, part design and printing parameters also have a great influence on the matching degree of printed parts with the original design.

Printer Quality

There is a big gap between high-end printers and entry-level printers in terms of quality. For example, SLA 3D printers are generally more accurate than FDM printers, but very low-cost SLA machines produce parts with lower accuracy than high-end FDM printers.

Part Design

Even the best 3D printers can hardly accurately print poorly designed parts. Long and thin parts—especially those without adequate support—are difficult to print, and very large parts can cause problems. In general, the design should not include features smaller than the printer can handle.

Materials

Some materials are easier to print than others, so they are more conducive to the manufacture of precise parts. Non-standard materials (such as flexible FDM filaments, high-temperature filaments or alloys containing precious metals) often sacrifice printability in order to obtain their unique advantages.

Printing Parameters

In addition to calibration-which is the key to accurate printing-users can also modify the settings of the 3D printer to achieve various results. Some parameter configurations are better at fast printing, while others are better at accurate printing.

4. How to Improve 3D Printing Accuracy

Although you cannot adjust a cheap 3D printer to industrial quality parts, users can change certain printing parameters and take other important steps to achieve better 3D printer accuracy.

- Consider the printer when designing components; Remove or simplify difficult functions.

- Export STL files with the highest resolution.

- Calibrate the 3D printer regularly or before important printing tasks.

- Use supports to stabilize the object during printing and be careful when removing supports to avoid damaging parts or changing their final dimensions.

- Use a heated printing bed (FDM) or heating chamber (SLS/metal) to keep the temperature of the whole part consistent and reduce deformation.

- Adjust the tension of the printer belt to ensure that the belt is tight and not too tight. The transmission gear should not slip.

- Straighten the linear rods and guide rails and lubricate them where needed. Immediately replace bent rails and rods.

- Reduce the printing speed by adjusting settings such as flow rate. Although reducing too much can cause other problems, slow printing can help reduce inaccuracies.

5. How warpage and shrinkage affect the accuracy

Most 3D printing technologies will produce a small amount of deformation during the printing process, the most common ones are warpage and shrinkage.

Parts that show signs of bending and shrinkage will be less accurate than those that don’t, because deformation will eventually change the final shape and size of the part. In most cases, the degree of deformation is negligible. However, for key parts, it is important to try and mitigate these adverse effects.

Methods to prevent warpage and shrinkage include using advanced printing simulation software, using heated printing beds and printing rafts (FDM), using low melting point materials (FDM), using harder materials (resins), and leaving the finished product in the printer Medium period of time (SLS), Or simply use techniques like material jetting in places where deformation is unlikely.

Leave A Comment