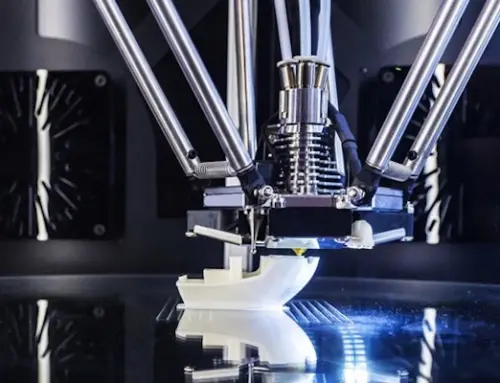

Thanks to the advancement of resin 3D printing technology, additive manufacturing is becoming the main technology in the dental field-whether it is through the dental practice of “chairside” 3D printing, or in off-site dental laboratories that require more printing work.

Dental laboratories can use a wide range of 3D printers today, from printing models to make thermoset tooth aligners, to directly 3D printing complete dentures.

This not only makes the life of dental professionals easier but also brings tangible benefits to patients: customized dental solutions are now more effective and more affordable than ever before.

Although resin 3D printing (stereolithography, DLP) is a leader in dental additive technology, metal additive manufacturing and ceramic 3D printing also have future possibilities. The current leaders in dental 3D printing technology include Form labs, 3D Systems and Stratasys, and there are also many startups in this field. Of course, 3D printers can’t do all the work on their own.

In addition to dental 3D printing, new dental CAD software and 3D scanners that capture dental anatomy are being introduced as well. These three systems are usually used together to create the final product. 3D printing in dentistry is examined in this guide.

1. 3D Printed Dental Braces

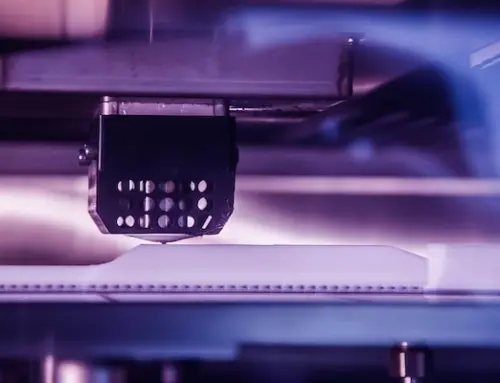

The most popular dental 3D printing application is, to a certain extent, 3D printed models are used to create patient-specific dental aligners. Dental solutions like Invisalign use resin 3D printers to make accurate models of the patient’s teeth, which are then used to make clear aligners.

This application is an example of indirect 3D printing: 3D printed objects are not final products but are used to create final products. (The 3D printed objects will eventually be discarded.)

For dental appliances, dental professionals first use a desktop or intraoral scanner to obtain a scan of the patient’s oral cavity. The scan data is converted into a CAD model, which is edited to reflect the required tooth movement.

The completed design then uses 3D printing techniques such as stereolithography. This 3D printed model-a complete copy of the patient’s teeth and recommended adjustments-is then placed in a dental thermoforming machine, where a clear aligner is tightly wrapped around the printed model to create a patient-specific final product. The aligner must be cleaned and polished before being delivered to the patient.

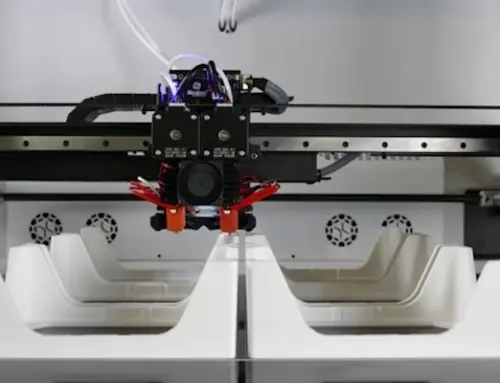

2. 3D Printed Dentures

Dental 3D printers can also be used for direct 3D printing, where the final product manufactured by the printer does not require further manufacturing steps. An example of direct printing is the 3D printing of complete dentures: a movable plastic frame is fitted with a full set of teeth, for patients who have no remaining teeth.

Denture printing is usually divided into two stages: the base that contacts the patient’s gums should be made of a resin that is softer than the teeth, and the teeth need to be strong. Since 3D printed dentures will be used in the patient’s mouth, they must be thoroughly polished to remove any rough or sharp defects.

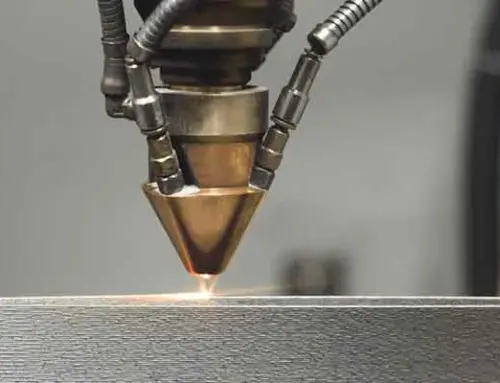

3. 3D Printing Casting Mode

Another indirect dental 3D printing application is 3D printing in casting mode. These patterns can be used to cast items like crowns, bridges and copings. Long before the advent of 3D printing, dental technicians have begun to use casting, but 3D printing can simplify this process and produce better end products.

The model is 3D printing, then cleaning, and then used in the investment casting process. During the burn-out stage of the process, the 3D printed pattern is burned away, leaving a cavity that can be filled with casting material.

4. 3D Printed Surgery Guide

One of the most important uses of 3D printing in the medical industry is to create 3D printed surgical guides to assist in surgical procedures. The same concept is also applied to the dental field.

In dental surgery, surgical guidance is used to ensure, for example, that the implant is accurately installed in the correct place. Apply them to the patient’s mouth before surgery and remove them during or after the surgery.

Specific guide types include drilling guides and drilling templates. Most surgical guides are designed using 3D scan data and then configured into a suitable CAD design. Digitally oriented design is printed, then polished, and finished, so it is ready for oral use.

5. 3D Printed Dental Model

3D printing can be used to directly manufacture 3D printed full arch models or crown and bridge models and detachable molds. By using models like these, dentists can plan for procedures such as dentures restorations.

The scan is obtained from the patient’s mouth and then converted into a CAD file. Dental CAD applications allow the automatic creation of movable molds in the software. Then, before washing, curing, and removing the support, the document can be printed in a hard resin.

Holly provides a series of high-quality 3D printing services, including stereolithography, FDM (plastic), SLS (nylon) and SLM (metal).

Leave A Comment