Do you seek China’s leading aerospace plastic parts suppliers to meet your precision engineering needs? China has become the world’s aerospace manufacturing base with plastic molding, CNC machining, and injection at global industry standards. Chinese suppliers offer everything from light structures to complex interior pieces, merging innovation, precision, and scale to supply local and global aerospace purchasers.

Following are China’s Top 10 Aerospace Plastic Components Manufacturers in more detail, from capacity to quantity, and what competitive edge at the top of the list. Whether you purchase airplanes, satellites, or drones, these are the manufacturers to watch out for so you can have quality, performance, and reliability.

1. List of Aerospace Plastic Components Manufacturers in China

The top Chinese aerospace plastic parts suppliers and their websites, and the years they were founded, are as follows for your reference.

| NO. | Company | Website | Year Established |

| 1 | Yijin Hardware | https://yijinsolution.com/ | 2003 |

| 2 | Holly Plastic | https://www.hollyplasticparts.com/ | 2000 |

| 3 | Gensun Precision | https://www.china-machining.com/ | 2006 |

| 4 | First Mold | https://firstmold.com/ | 2011 |

| 5 | Neway Precision | https://www.newayprecision.com/ | 1993 |

| 6 | LS Manufacturing | https://www.longshengmfg.com/ | 2019 |

| 7 | Pans Technology | https://www.pans-cnc.com/ | 2021 |

| 8 | REGO Mould | https://www.regomould.com/ | 2008 |

| 9 | ZC Precision Mold | https://zcsmould.com/ | 2016 |

| 10 | TDL Mould | https://tdlmould.com/ | 1995 |

2. Top 10 Aerospace Plastic Components Manufacturers in China

The top Chinese aerospace plastic parts suppliers are as follows. They are all well known for their technical capability, precision manufacturing capability, and good service to the global aerospace market.

Top 1: Yijin Hardware

Yijin Hardware is a Chinese company that produces high-precision machined and plastic components, established in 2003. Yijin has a history of supplying high-precision components for aerospace with the highest level of CNC machining, plastic injection molding, and overmolding operations. Yijin’s advanced manufacturing facilities have the latest machines and computerized devices to offer close tolerance, high-quality surface finishes, and reproducible quality for demanding aerospace uses.

Yijin Hardware R&D team has experience in processing various engineering plastics, such as PEEK, PTFE, Ultem, and PPS, according to aerospace and defense industry high standards. Yijin Hardware has a good brand image in providing services to its clients in Europe, North America, and Asia through high-quality and light, strong, and precise value-added solutions.

ISO 9001 and AS9100-certified process allows Yijin to obtain complete traceability and reliability in every single part shipped, hence the most transparent progressive Chinese aerospace plastic parts supplier. With a continuous improvement policy and a rigorous quality inspection, the company is positioned to offer cost-saving yet high-precision solutions to leading international aerospace customers.

Website: https://yijinsolution.com/

Year established: 2003

Location: Shenzhen, China

Products:

- Aerospace plastic components

- CNC-machined parts

- Injection molded parts

- Overmolded assemblies

- Precision metal-plastic hybrids

Top 2: Holly Plastic

Holly Plastic has been a top manufacturer of specialty plastic parts utilized in aerospace, automotive, and industrial markets since 2000. Holly Plastic has been in business for over twenty years and has become a reliable high-strength lightweight part designer to meet the uncompromising demands of the aerospace sector. Holly Plastic has very sophisticated injection molding and high-precision machine shops with computerized production lines in an attempt to achieve consistent high-quality and efficiency.

Holly Plastic product families include high-performance plastics such as PEI, PPSU, and PEEK that facilitate the manufacturing of aircraft parts to withstand corrosive and high-temperature aircraft environments. The Holly Plastic engineering department is providing turn-key services from prototyping and mold design through high-volume production and assembly, and is providing the customer with the capability to optimize lead times and performance.

Committed to international standards, Holly Plastic has attained ISO 9001 and ISO/TS 16949 certifications to instill every part with aerospace-level strength and precision. It is also reinforcing its international links by providing the aerospace sector with value-for-money, creative, and reliable plastic solutions.

Website: https://www.hollyplasticparts.com/

Year established: 2000

Location: Zhejiang, China

Products:

- Aerospace plastic components

- Precision injection-molded parts

- Custom molds

- Plastic enclosures

- Functional prototypes

Top 3: Gensun Precision

Gensun Precision Machining began operations in 2006 and is among China’s top providers of precision-machined metal and plastic aerospace components. Based in Dongguan, the company utilizes the latest CNC machining, injection molding, and finishing technology to produce airplane subsystems and interior assembly components with high precision. Gensun plants are among the world’s best-equipped, and the newest generation 5-axis machining centers and precision molding machines have complex geometries.

It employs various aerospace-grade plastics such as Ultem, PEEK, and PPS to develop lightweight yet robust solutions to high-end industry needs. Quality and high consistency are Gensun’s concerns, where it employs the latest equipment, such as CMM and optical measurement, to provide accuracy.

ISO 9001 and ISO 13485 certified, Gensun Precision boasts its excellence in project management, fast turnaround prototype factory, and high-level customer service. Gensun Precision has been successfully serving the aerospace customers in North America and Europe with stable and scalable production capacity for high-performance applications.

Website: https://www.china-machining.com/

Year established: 2006

Location: Dongguan, China

Products:

- Aerospace plastic parts

- CNC-machined components

- Plastic injection parts

- Rapid prototypes

- Molded assemblies

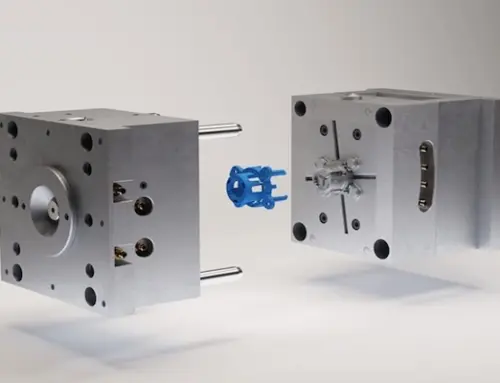

Top 4: First Mold

First Mold is a precision industrial and aerospace application plastic part injection mold and tool factory established in 2011. With headquarters in Shenzhen, the business corporation provides one-stop mold design, rapid prototyping, and mass production for the convenience of project implementation and production efficiency. First Mold utilizes a series of high-speed injection molds with different capacities ranging from 50 tons to 1,000 tons in manufacturing complicated aerospace plastic parts.

Its flight-grade metal experience enables it to produce parts that are high in strength but low in weight and can also withstand thermal and mechanical stresses throughout the flight. Overmolding, insert molding, and high-gloss surface molding are also offered by First Mold to meet the various needs of aerospace designs.

Committed to performance and accuracy, the company is committed to quality management system management by ISO 9001 and IATF 16949. It has achieved long-term business cooperation with global automotive and aerospace customers on the grounds of timely and innovative delivery.

Website: https://firstmold.com/

Year established: 2011

Location: Shenzhen, China

Products:

- Aerospace plastic components

- Precision injection molds

- Overmolded parts

- Insert molded parts

- Rapid prototypes

Top 5: Neway Precision

Neway Precision, established in 1993, is an experienced precision plastic injection molding and CNC machining company with a background in aerospace and defense parts. Its Suzhou plant features gigantic production workshops with more than 200 injection machines and auto inspection lines. With its advanced equipment and strict process control, it guarantees the quality and reliability of each aerospace-level product.

Neway Precision specializes in machining PEEK, PPS, and PTFE high-performance materials that are commonly used in aircraft interior and cockpit system-related structure assembly applications. Neway Precision offers the entire series of products, including product design and prototyping, volume production, and post-processing, and delivers end-to-end full manufacturing solutions.

Neway is at the top level of norms as per international aerospace industry standards by being ISO 9001, ISO 14001, and AS9100 certified. The more than three-decade-old company still provides European and North American prime aerospace customers with high-precision machined, robust, and lightweight plastic components.

Website: https://www.newayprecision.com/

Year established: 1993

Location: Suzhou, China

Products:

- Aerospace plastic components

- Precision injection-molded parts

- CNC-machined parts

- Mold design and fabrication

- Structural plastic assemblies

Top 6: LS Manufacturing

LS Manufacturing (Longsheng Hardware Technology Co., Ltd.) was founded in 2019 as a new precision CNC machining, plastic injection mold, and metal processing factory for aerospace, robotics, and medical equipment manufacturers’ production. LS Manufacturing offers stable quality, high accuracy, and short lead time with the newest state-of-the-art multi-axis machine centers and auto molding lines.

The company is a leading manufacturer of high-quality metal and plastic composite components with aerospace-level strength, hardness, and lightness. The company’s engineering team helps customers with material selection, DFM optimization, and prototyping to provide stable and low-cost assembly components and flight components.

ISO 9001 certified, LS Manufacturing boasts strong continuous improvement and quality audit regimes and practices. Biased towards agility, accuracy, and responsiveness, it has carved a niche as the best-fit supplier for global aerospace customers requiring innovative and dependable component solutions.

Website: https://www.longshengmfg.com/

Year established: 2019

Location: Guangdong, China

Products:

- Aerospace plastic components

- CNC-machined parts

- Metal-plastic hybrid assemblies

- Injection-molded parts

- Rapid prototypes

Top 7: Pans Technology

Pans Technology is a Shenzhen-based precision machine and injection plastic business, founded in 2021, with a presence of offices. So early in the process, the company already has a reputation due to its state-of-the-art manufacturing machines as well as attention to quality. Pans Technology provides CNC machining, injection molding, as well as assembly services to high-performance industries such as aerospace and defense.

The firm has a high-tech facility with multi-axis CNC machines and precision injection molding machines to machine engineered plastics such as PEEK, PPS, and PEI, and intricately shaped parts. The firm’s experienced engineers offer one-stop-shop services from design check and prototyping to production quantity with predictable results and on-time delivery.

Pans Technology is AS9100 and ISO 9001 quality system standards certified with aerospace severity of process and documentation. With the good quality customer service along with technology development, Pans Technology is now known as a potential supplier of precision plastic parts for aerospace.

Website: https://www.pans-cnc.com/

Year established: 2021

Location: Guangdong, China

Products:

- Aerospace plastic components

- CNC-machined parts

- Injection-molded components

- Assembly and finishing services

- Custom tooling

Top 8: REGO Mould

REGO Mould is a mould and injection mould parts mould-making company established in 2008 with a specialty in precision tooling and making plastic components. The company is headquartered in Taizhou, China. The company offers one-stop design-to-production to produce high-performance plastic components to cater to aerospace, industrial, and automotive markets.

REGO Mould is able to produce high-tolerance and intricate geometry moulds with less lead-in time on state-of-the-art CNC, EDM, and injection machines. Its engineering department has found widespread applications of engineering plastics such as PPS, PEEK, and PEI in an effort to create weight-saving heat-resistant parts that find application in aircraft interior parts and equipment housing.

Since it is equipped with ISO 9001-certified production processes, REGO Mould enjoys traceability, repeatability, and accuracy in the production process. Its accuracy-driven mindset in molds as well as in quality inspection has enabled the company to get repeat orders from foreign aircraft parts producers.

Website: https://www.regomould.com/

Year established: 2008

Location: Zhejiang, China

Products:

- Aerospace plastic components

- Precision injection molds

- CNC-machined parts

- Mold design and maintenance

- Prototype tooling

Top 9: ZC Precision Mold

ZC Precision Mold (Dongguan Zecheng Precision Mold Co., Ltd.) was established in 2016 and is a specialist injection mold factory and aerospace, automotive, and electronic plastic components. Headquartered in Dongguan, Guangdong, the company provides industry solutions through the combination of advanced mold design and precision manufacturing to produce greater quality and long-lasting plastic components.

ZC Precision Mold’s experience is to work together with high-strength engineering plastics such as PEEK and PPS for producing components with high strength and heat resistance for aerospace applications. It is its quick CNC machining, EDM, and robot mold process in order to achieve close tolerances, better surface finishes.

Innovating and quality-oriented, the company employs ISO 9001 quality control standards in its manufacturing process. Its effectiveness and precision are being tested and verified, and it is presently a competitive option among Chinese next-generation aerospace plastic part manufacturers.

Website: https://zcsmould.com/

Year established: 2016

Location: Guangdong, China

Products:

- Aerospace plastic components

- Precision injection molds

- Molded assemblies

- Connector molds

- Prototype parts

Top 10: TDL Mould

TDL Mould (TDL Plastic Mould Co., Ltd.) is a precision mould and injection moulding expert located in Dongguan, China, founded in 1995. With nearly three decades of practice, TDL supplies one-stop tooling and moulding services for aerospace, automotive, and medical industries. TDL specializes in making very accurate, complicated plastic parts of very uniform quality.

TDL Mould applies computer-aided mold design technology, a multi-cavity shot machine, and a high-speed machining center to manufacture aerospace parts with near tolerance. It possesses engineering plastic technological capabilities such as PEEK, PPS, and Ultem for creating products that will withstand durability and weight in aerospace applications.

Having been constructing the ISO 9001 and AS9100 standards, TDL demands accuracy, traceability, and delivery on time. With decades of foreign project experience and an old company with tradition, it is currently China’s leading aerospace plastic component supplier.

Website: https://tdlmould.com/

Year established: 1995

Location: Guangdong, China

Products:

- Aerospace plastic components

- Precision injection molds

- CNC-machined parts

- Molded assemblies

- Prototype tooling

3. Best Tips to Select the Best Aerospace Plastic Components Supplier

The choice of a trustworthy aerospace plastic components supplier is a key element of product reliability, regulatory compliance, and repeatability of performance. Since the majority of Chinese suppliers vary in material, technology, and certification, there has to be one that is pitted against the other on the dimension of crucial technical and operational parameters. The following is helpful advice on making an informed decision.

1) Possess quality management systems and certifications. Space activity is highly accurate and traceable. Ideally, only ISO 9001, IATF 16949, or AS9100 certification by suppliers, since it indicates rigorous quality control and adherence to international aerospace standards.

2) Evaluate material experience. Aerospace is full of high-performance materials such as PEEK, PPS, Ultem (PEI), and carbon fiber-reinforced plastics. Their previous material-processing experience will allow them to add more strength, thermal stability, and light weight.

3) Obtain engineering and design assistance. The ideal supplier would offer DFM (Design for Manufacturability) consulting, CNC machining, and injection molding simulation to maximize the design as much as possible before manufacturing. It reduces risk and slashes development time.

4) Track manufacturability and scalability. Aerospace manufacturing includes prototype lots and volume production. Select a contractor that is proficient in both, with computer-aided support equipment, precision fixtures, and effective test systems.

5) Consider test stability and long-range communications. Project feedback, clarity, technical reporting, and post-sale service are most important. Successful partners have a quick response and permit flexible project change requirements.

To keep this in mind, you can get a good Chinese manufacturer that can deliver quality aerospace components according to international standards.

4. Conclusion

The Chinese aerospace plastic parts industry is expanding at a very rapid pace, and the giants have high innovation levels, high precision, and high quality. These are reliable partners who are able to supply lightweight, high-performance, and high-durability aerospace products globally. With the demand that needs to increase even more, the companies are set to offer a wider solution and end-to-end full-service in meeting evolving aerospace requirements globally.

Leave A Comment