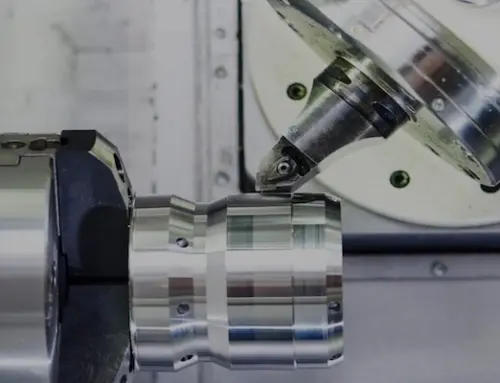

In the manufacturing field, customized CNC machining services are one of the most important links. It is the process of using different tools to eliminate material on high-speed precision machine tools.

It provides different technologies to produce products, and you can choose the best method according to the needs of your next project. The CNC custom machining service also includes 5-axis machining, including 3 linear axes and 2 other rotary axes, and takes the form of a turntable on the main shaft and headstock of the machine tool.

This is another top-notch solution you can get from your manufacturing team. When it comes to the most complex and requires high precision, it is highly used. You can expect much higher precision with this manufacturing method. You can get different advantages from the five-axis custom machining service.

This article will discuss all the advantages of this method, you only need to understand them in depth.

1. Advantage of 5 Axis Machining Process

There are 5 main advantages of the 5 Axis machining process.

1) Accurate and Affordable Parts

If you need to complete the most complex parts in one step, then you must consider five-axis machining, which also reduces machining time, errors and tool costs.

It ensures faster, accurate and affordable results for your next project. You can get precise accuracy without compromising the required accuracy to maintain quality. It can achieve low cycle times when removing more material each time the tool passes.

2) Higher Speeds

five-axis machining enables shorter tools to consider the surface on which the head can be lowered and the tool is guided. You can get higher cutting speeds and tool vibrations and the best results you can expect.

3) Reduced Setup

5-axis machining ensures you work on different surfaces at the same time. Usually, in other techniques, you need to make several settings to get complex geometry by manual rotation. However, five-axis machining can reduce all these stresses.

This advanced method is sufficient to handle extremely complex parts from solids. When it comes to different materials, it can also handle several raw materials, including high-temperature alloys such as tool steel, carbon steel, standard silver, brass, stainless steel, bronze, etc.

4) Save Time

this cutting-edge machining solution can save you time, when it comes to drilling, it will take a lot of time, using compound angles. With five-axis machining, the head of each hole can be easily positioned along the right axis.

5) Excellent Polishing

The last 2 axes will help you position and take the part closer to the cutting tool. Cutting tools can be used shorter and surfaces can be finished more efficiently.

Here, another most important thing is to consider hiring a professional manufacturing company that can help you achieve your exact needs and specifications for your next project.

Since money and time are precious, you need to use them appropriately to make sure you are in the right place. Therefore, here we will share some basic tips to make this process easier for you.

2. Outsource Five-axis machining services

Make sure your manufacturing team has been operating for a long time. They should have rich experience and skills to ensure work quality and turnover. A company should be reliable and trustworthy.

Don’t hesitate to ask some questions about five-axis machining before the company has a decision. The quality of the machine must also be higher, and the work can be completed within the specified time. Ask about their service fees.

Make sure you pay for what you get, it should match the quality of the product. At the same time, be aware of the materials they will use.

Holly is a leading plastic injection molding company that provides five-axis machining services.

Leave A Comment