From automobiles to consumer electronics, to kitchenware, Delrin is everywhere: high-strength thermoplastics make great consumer products, and they are favoured by mechanics for their good material properties and high processability.

This article will introduce the basic knowledge of processing Delrin: what is Delrin, the benefits of processing Delrin, the limitations of processing Delrin, the common applications of processing Delrin, and the skills of designing and processing Delrin parts.

1. What is Delrin?

Polyoxymethylene (POM) is a semi-crystalline engineering thermoplastic with good stiffness, dimensional stability, hardness and strength. It is also known as acetal, polyacetal or polyoxymethylene, and its best-known brand name is Delrin, produced by the chemical company DuPont. (POM’s other brands include Kocetal, Ultraform and Celcon.)

Please note that Delrin is an acetal homopolymer, but polyoxymethylene can also be made into copolymers. Although opaque in nature, Delrin is available in a variety of colours. It has a density of 1.410-1.420 g/cm3 and a rigidity of -40°C. Its crystallinity is 75-85% and its melting point is 175°C.

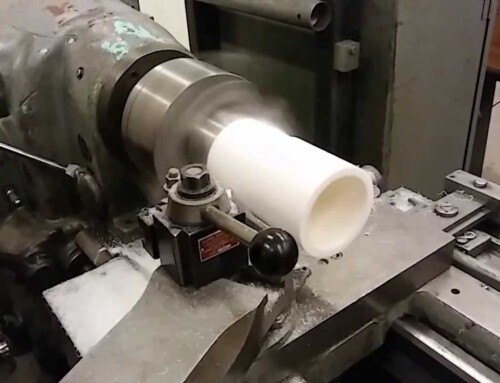

Delrin is suitable for machining processes, such as milling and turning, and provides plates or extruded bars for this purpose.

The material can also be cut with a laser cutter, and its pellet form is used for injection molding and plastic extrusion.

2. Advantages of Machining Delrin

Due to its material properties and processability, Delrin is a popular engineering thermoplastic for CNC machining. Its main advantages are:

- Machinability: Delrin is an easy-to-cut plastic with good dimensional stability. This makes it easy to cut to tight tolerances.

- Strength, toughness and impact resistance: Delrin is a tough, high-strength material suitable for demanding applications.

- Moisture and chemical resistance: Delrin is resistant to solvents, gasoline, alcohol and other chemicals, as well as moisture.

- Creep resistance: Delrin has good creep resistance and is suitable for long-life end products such as auto parts. It also provides good fatigue endurance.

- Electrical insulator: Due to its electrical insulating properties, Delrin is a popular processing material in consumer electronics.

- Natural lubricity: Delrin has a high level of natural lubricity, so it is a good choice for low-friction applications where the part will come into contact with other plastic parts.

3. Limitations of processing Delrin

Delrin machining has some limitations that make it unsuitable for certain parts and applications. Its main limitations and weaknesses are:

- Adhesion: Due to its chemical resistance, Delrin does not react well to adhesives, making it difficult to bond-although Delrin is slightly easier to bond than POM copolymers.

- Flammability: Delrin will not self-extinguish and will not burn until oxygen is eliminated.

- Class A fire extinguishers are required to extinguish POM fires.

- Heat sensitivity: Processing Delrin at too high a temperature will cause deformation. Although this can be controlled, it does require attention.

4. Application of Delrin processing

From the automotive industry to consumer electronics, mechanical Delrin parts can be seen everywhere. Some common Delrin processing applications include:

- Machinery/Industrial Parts: Delrin mechanical components can include gears, housings, springs, fan wheels, valves, bearings, rollers and scrapers.

- Electrical parts: Delrin components used in electronic applications include insulators, connectors, spools, connectors, and consumer electronic components such as keyboard covers.

- Car Parts: Delrin automotive components include a door lock system, hinged housing and fuel delivery unit.

- Medical Part: Delrin medical components include inhalers, insulin pens and medical devices.

- Furniture: Delrin can be processed into furniture parts such as handles, locks, hinges and hardware.

5. Tips for Acetal Resin Processing

Delrin is widely regarded as one of the easiest plastics to process, so it does not require any drastic precautions. In other words, it responds better to certain design considerations and processing methods than others.

- Delrin Design: When designing parts processed by Delrin, try to keep the wall thickness consistent, including fillets and ribs if necessary. Large parts may be more likely to warp.

- Stay cool: Delrin is sensitive to temperatures above 121°C. Air-based coolants perform better than liquid coolants and also speed up chip removal.

- Keep the Tools Clean: Although the machined Delrin will produce stable and easy-to-handle chips, the chips should be removed quickly to avoid the formation of jelly on the tools.

- Keep the Delrin Apart: In order to avoid contamination, it is best to use cutting tools that have not been used before to cut aluminium or other metals.

- Sharpness: When machining Delrin, a sharp tool with a high clearance angle will provide better results, and the use of cutting lubricants may also help.

- Don’t be too tight: Delrin is not particularly hard, so be careful when working. A light clamping force should be used at all times.

6. Delrin machining, Delrin 3D printing, or Delrin injection molding?

Delrin is a multifunctional material, not limited to CNC machining. Delrin 3D printing filament can be used to make 3D printed Delrin parts, or it can be injection molded with Delrin.

3D printing Delrin provides geometric flexibility and is suitable for a very wide range of prototyping applications, but its limitations include poor print bed adhesion, possible delamination, and a limited temperature range. Injection molding Delrin is suitable for larger parts and is more reliable than 3D printing.

POM particles (Delrin or acetal copolymer) used for IM are also more extensive than Delrin 3D printer filaments. However, the semi-crystalline nature of Delrin can increase the shrinkage of molded parts.

Generally speaking, if the Delrin parts of the required geometry and size are machinable, then machining is the best choice among the three.

| Machining | 3D printing | Injection molding | |

| Large-volume parts | Sometimes | No | Yes |

| Thick-walled parts | Yes | Yes | No |

| High-performance parts | Yes | No | Yes |

Holly is a CNC machining expert with expertise in Delrin machining. Contact us for a free quote for your next Delrin prototype or Delrin part.

Leave A Comment