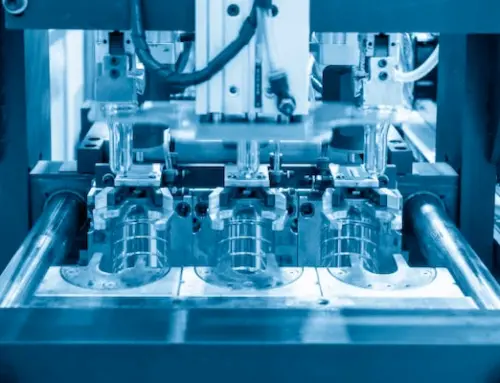

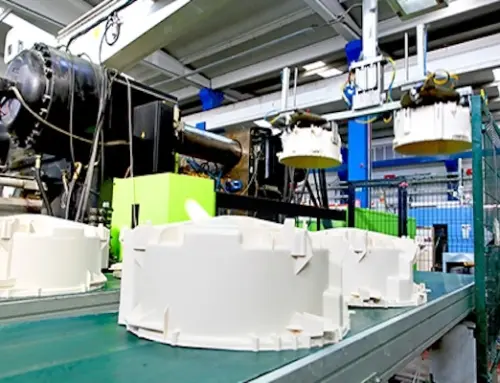

Would you like to witness the world’s highest-rated auto plastic injection molding plants make your car parts a reality? From extremely small interior trim components to extremely long-lasting exterior ones, plastic injection molding is an extremely crucial part of car production today. It is extremely unusual for world-class, high-rated factories to possess top-class potential, massive volume, and assured quality. In this article, we’ll take an in-depth look at the top 10 automotive plastic injection molding companies worldwide, examining their strengths, technologies, and what sets each of them apart in this competitive industry.

1. List of Automotive Plastic Injection Molding Companies Worldwide

The following companies are recognized globally for their expertise in automotive plastic injection molding, offering a wide range of services from prototyping to full-scale production.

| NO. | Company | Website | Year Established |

| 1 | Holly Plastic Parts | https://www.hollyplasticparts.com/ | 2000 |

| 2 | Flex-N-Gate | https://flex-n-gate.com/ | 1956 |

| 3 | Magna International | https://www.magna.com/ | 1957 |

| 4 | Custom Plastics, Inc. | https://www.customplasticsinc.com/ | 1955 |

| 5 | Manar, Inc. | https://manarinc.com/ | 1974 |

| 6 | Ohio Precision Molding | https://www.ohioprecisionmolding.com/ | 1994 |

| 7 | VEM Tooling | https://www.vem-tooling.com/ | 1998 |

| 8 | Cumberland Plastic Solutions | https://cumberlandps.com/ | 2006 |

| 9 | Shin-Etsu Polymer | https://shinpoly.com/ | 1960 |

| 10 | Wabash Plastics | https://wabashplastics.com/ | 1973 |

2. Top 10 Automotive Plastic Injection Molding Companies Worldwide

Automobile plastic injection moldings are pillars of support to the production of high-quality and durable components that can withstand the new automobile’s high standard level. With all that has been stated above, hereunder, we introduce to you the top 10 world-class leading companies that stand on the cutting edge of automobile plastic injection molding quality, innovation, and accuracy.

Top 1: Holly Plastic Parts

Holly Plastic Parts, founded in 2000, is the number one auto parts plastic injection molding factory in China. Holly is a precision molding expert, offering cost-effective benefits and rapid turnaround of high- and low-speed. Holly possesses more than twenty years of experience in an operational business firm with an unstained reputation in the position of global automobile original equipment maker and Tier 1 suppliers.

With over 50 presses ranging from 1,200 to 60 tons, Holly can make parts in both size and complexity. Turnkey operations, including in-house mold design, specialty tooling, prototyping, high-volume manufacturing, and post-molding assembly, are offered by Holly. Holly is IATF 16949 and ISO 9001 certified and compliant in order to produce high-quality products required in the auto industry.

Among Holly’s major strengths is response and engineering assistance in the field of working on product development at early stages. Holly has assisted EV start-ups with dashboard parts, such as trim to reduce weight, and worked with global automobile producers for products under the hood. Holly also offers value functions like ultrasonic welding, painting, and EMI shielding for high-performance applications.

Website: https://www.hollyplasticparts.com/solution/automotive-plastic-injection-molding/

Year established: 2000

Location: China

Products:

- Instrument panels

- Air vent grilles

- Door trim components

- Under-hood parts

- Lighting housings

- Structural brackets

Top 2: Flex-N-Gate

Flex-N-Gate, which was founded in 1956 and has its headquarters in the United States of America, is one of the largest plastic injection molding companies engaged in the global motor vehicle industry. It boasts more than 70 facilities across the globe and more than 26,000 employees, in addition to supplying its products to some of the largest motor vehicle manufacturers globally, like Ford, GM, Toyota, and Honda.

Flex-N-Gate is most renowned particularly for vertically integrated manufacturing, including in-plant painting, assembly, molding, tooling, and design. Injection molding ranges from small decorative trim parts right up to enormous fascia-type bumpers.

Lean manufacturing and the constant improvement culture of Flex-N-Gate have established it as the go-to, first-choice supplier to the EV and ICE platform supply business. It has been possible for it to produce front-end structures with weight efficiency, un-compromised energy-absorbing performance, and fully integrated light solutions. OEM compliance and, thus, time to market can be achieved by the customer through prototyping and test facilities that are part of Flex-N-Gate.

Website: https://flex-n-gate.com/

Year established: 1956

Location: United States

Products:

- Bumper fascia systems

- Grilles

- Exterior trim parts

- Lighting housings

- Instrument panels

- Airflow and fluid management components

Top 3: Magna International

Established in 1957 in Canada, Magna International is the world’s largest plastic injection mold supplier and the world leader among automakers’ suppliers, and provides nearly all the world’s largest automakers with its complete range of engineered plastic products from more than 340 plants and more than 180,000 employees in 28 nations on the globe.

The champion of the Interior and Exterior Systems business units is Magna’s injection molding plastic. Efficiency, material reuse for weight savings, and recycling plastic are marketing drivers of company expansion. Due to company R&D investment, it can engineer active aerodynamics systems and sensor integration on ADAS and EV platforms, and enable its engineering prowess to back up with OEMs on co-development of parts by evolving vehicle requirements from stiffness to beauty.

Its highly complex show-stopper products range from multi-part bumper modules on prestige SUVs to gloss interior consoles on electrics, to mention nothing of camera-based exterior trim for autonomous vehicles. Magna’s scale, technology, and dependability make it an automaker’s unparalleled supply base partner.

Website: https://www.magna.com/

Year established: 1957

Location: Canada

Products:

- Bumper assemblies

- Exterior body panels

- Front-end modules

- Instrument panels

- Center consoles

- Trim and garnish components

Top 4: Custom Plastics, Inc.

Custom Plastics, Inc., Illinois, USA, 1955-present, is a plastic component supplying service to the automobile sector. Also renowned for responsivity and speediness, the business is a high-end injection molder market leader to car OEM and Tier 1 supply, for special finish, close-tolerance application specialty.

It resides in a 200,000-square-foot facility and offers injection molding capacity from 35 to 720 tons. It has in-depth manufacturing capability by way of part design assistance, mold building, prototyping, high-volume molding, and post-molding. It is ISO 9001 certified and maintains strict quality control protocols particular to the automotive sector.

It has supplied interior trim parts, cover housing, bracket assembly, and specialty infotainment enclosures to OEM auto original equipment manufacturers. Its mid-to-low volume capability is also well positioned to be a go-to supplier of lower-volume vehicle platforms and aftermarket.

Website: https://www.customplasticsinc.com/

Year established: 1955

Location: United States

Products:

- Interior trim components

- Electronic housings

- Mounting brackets

- Custom enclosures

- Overmolded connectors

- Decorative bezels

Top 5: Manar, Inc.

Manar, Inc., established in 1974 in Michigan, USA, is a globally recognized plastic injection molding solutions provider to the automotive industry. It is a high-precision and quality interior and exterior component specialist with experience in close tolerance and very complicated geometry handling.

With its unique focus on quality and customer satisfaction, Manar boasts a range of state-of-the-art injection molding machines and is capable of delivering high-volume production, prototyping, and mold-making. Manar is ISO 9001 and IATF 16949 certified to guarantee that all the components meet the high-quality levels of the automotive sector.

Manar technical capability employs overmolding, insert molding, and multi-component assembly on a daily basis to create door handles, control knobs, and trim decorative parts. Manar works very closely with automobile original equipment makers as a way of dealing with form and function requirements. Manar was able to develop customer relationships over the long term, and thus Manar was able to be a reliable partner in car parts.

Website: https://manarinc.com/

Year established: 1974

Location: United States

Products:

- Door handles

- Control knobs

- Trim components

- Overmolded parts

- Insert molded components

Top 6: Ohio Precision Molding

Ohio Precision Molding is a well-experienced auto plastic injection molding company with operations based in Ohio, USA. Founded in 1994, the company has extensive experience in producing high-precision components with strict tolerances and is well-equipped for multi-part complicated assemblies for the auto industry.

Ohio Precision Molding also boasts the latest technology with the most up-to-date state-of-the-art injection molding machines and prototype tooling, mold design and build, and secondary operations like paint, assembly, and sonic welding. Ohio Precision Molding is both ISO 9001 and IATF 16949 certified and offers customers ongoing quality.

Ohio Precision Molding specializes in the manufacture of under-hood components, interior trim components, and electrical system connectors. The projects include the manufacture of essential engine components and bespoke interior components, which offer form and function intelligence for electric and gas vehicles. Ohio Precision Molding’s high quality and large-scale production have earned it a position as a market leader in the auto industry.

Website: https://www.ohioprecisionmolding.com/

Year established: 1994

Location: United States

Products:

- Under-the-hood components

- Interior trim parts

- Electrical connectors

- Multi-material assemblies

- Engine components

Top 7: VEM Tooling

VEM Tooling, founded in 1998 as a German-style company, is a plastic injection tooling and plastic injection molding solution business firm in the automobile sector. Having a history of possessing precise mold technology, VEM Tooling is primarily involved in producing high-speed and high-quality complex car parts.

The company provides turn-key operations from the design and proto of molds, to production and secondary work of painting, etching, laser, and assembling. VEM Tooling features an ultra-state-of-the-art facility with state-of-the-art equipment to satisfy any injection mold from small lots to high volume production.

VEM Tooling specializes in the production of operating components of car interior pieces, such as dashboard pieces, switches, and climate control modules, and exterior pieces such as trim pieces. VEM Tooling is also an environmental specialist, with recycled content and energy-efficient production built into its processes.

Website: https://www.vem-tooling.com/

Year established: 1998

Location: Germany

Products:

- Dashboard components

- Switches

- Climate control modules

- Exterior trim parts

- Functional automotive parts

Top 8: Cumberland Plastic Solutions

Cumberland Plastic Solutions, headquartered in USA company of 2006, is one of the well-known plastic injection moulding solutions providers for the automobile sector. Cumberland possesses the experience to sustain quality levels, customer satisfaction, and an innovative attitude towards manufacturing long-lasting automobile components.

Cumberland is a complex design part, multi-material injection molding, and precision part injection molding high-performance company. Cumberland is a one-source supplier of the entire range of services from prototype and mold design through manufacturing and secondary operations like assembly, paint, and finish. Cumberland is ISO 9001 and IATF 16949 certified with high automotive levels of quality.

Its highest value Cumberland products are under-the-hood applications, interior trim applications, and structural applications. Cumberland’s capability to supply lightweight, high-strength parts for gasoline and electric vehicles has made Cumberland a preferred choice for OEMs and Tier 1 suppliers.

Cumberland’s capability to offer volume production and capability to keep up with the high speed of the automotive industry makes Cumberland a preferred supplier of several different automotive applications.

Website: https://cumberlandps.com/

Year established: 2006

Location: United States

Products:

- Under-the-hood components

- Interior trim parts

- Structural elements

- Multi-material assemblies

- Lightweight components

Top 9: Shin-Etsu Polymer

Shin-Etsu Polymer is the world’s top high-performance automobile plastic parts manufacturer and was founded in 1960 with its headquarters in Japan. It is the pioneer in the development of innovative injection mold technology and produces high-precision exterior and interior components with unparalleled attention to performance and reliability.

Shin-Etsu Polymer offers services that include prototype and mold design and production, post-finishing, and has state-of-the-art plants and high-tonnage injection molds. Shin-Etsu Polymer is both ISO 9001 and IATF 16949 certified, meaning products produced by them have automotive industry quality standards of specification.

It is very highly renowned for making components that end up in electronics. Shin-Etsu Polymer makes components such as connectors, sensor protectors, and high-performance outer trim pieces. It is also very highly skilled at overmolding, insert molding, and multicomponent assembly, and thus very highly demanded as a partner by OEMs for their requirement of complicated, high-performance components.

Shin-Etsu Polymer’s sustainability can also be seen in the way that the company creates products out of friendly materials and makes sure to cause the least damage to the environment during the production process.

Website: https://shinpoly.com/

Year established: 1960

Location: Japan

Products:

- Connectors

- Sensor housings

- Exterior trim components

- Overmolded parts

- Insert molded components

Top 10: Wabash Plastics

Wabash Plastics is a US company established in 1973 and a trusted supplier of plastic injection molded parts to the automotive sector. It is a distributor of high-precision, high-quality parts and is also able to provide creative exterior and interior design concepts for the vehicle.

Wabash Plastics is a volume producer of long-life, light-weight parts, including structural parts, under-hood parts, and interior trim parts. Wabash has in-house capability ranging from secondary to high-volume production, prototype to design, assembly to assembly, and assembly to specification, including painting and decorating. Wabash has ISO 9001 and IATF 16949 certifications, i.e., industry standards have been met by them.

Wabash offers tailored molding through overmolding and multi-component assemblies in its own niche. Wabash works with original equipment manufacturers and Tier 1 suppliers for the automobile industry to satisfy the evolving automobile demands.

Website: https://wabashplastics.com/

Year established: 1973

Location: United States

Products:

- Under-the-hood components

- Interior trim parts

- Structural elements

- Multi-material assemblies

- Overmolded parts

3. FAQs on How to Choose Automotive Plastic Injection Molding Companies?

Choosing the best-fit automotive plastic injection molding company is Tier 1s’ and OEMs’ most important choice, and it is not a matter of who can give you the lowest price. Below are some of the questions that you may like to ask:

1) What technical capabilities must I look for?

Technical expertise is directly relevant in determining the injection moulding partner. Choose partners with a track record of producing intricate, precision components. They should be capable of offering different methods of moulding like insert moulding, overmoulding, and multi-component assembly, which are the standard norms for automobile components.

2) How effective is green manufacturing?

Sustainability is not a choice. It is the responsibility of the firm to reduce its carbon footprint by any means. Recycling materials, low-carbon production, and waste reduction are all part of it. Request green initiatives and certifications proving a move towards sustainable business from prospective suppliers.

3) How does the company maintain quality control?

Quality control is one of the motor vehicle manufacturing requirements. Make sure that the company has a superior quality management system and ISO 9001 and IATF 16949 certifications. Ask about testing processes, such as material testing, mold inspection, and part validation, to produce uniformly and consistently.

4) What is their prototyping and flexibility strategy during production?

A good partner must be capable of performing tasks from prototype development in low-volume manufacturing to high-volume manufacturing. How well they can change and flex to the demands of the production process without loss of efficiency and quality is of greatest value. Flexible manufacturing capacity and inflexible lead times are of greatest advantage for flexible automobile programs.

Selecting an injection molding partner is more about discovering a faithful, innovative, and efficient partner that matches your needs rather than having parts produced.

4. Conclusion

Selecting the right auto plastic injection molding company requires time in consideration of various factors like technical ability, environmental awareness, and quality assurance. By knowing about the top 10 auto plastic injection molding companies through this report, you now know better about the best companies involved in this global automobile production venture. Having such knowledge, you now know better how to make a sound decision based on your requirements and ultimate goal. Are you ready with the audacity to choose a business ally who will support you to fulfill your car project dreams? In front of you, the facts. You can now proceed with confidence towards finalizing a good business deal with a good plastic injection molding firm.

Leave A Comment