The design of the product and the injection molding mold are both crucial factors for a successful injection molding project. Today, when a shorter lead time and better quality are needed, no one has time to make mistakes, so here is how you can do it right.

Plastic injection molding can be complicated and difficult to complete immediately, especially if you want to complete it on the other side of the world. You have heard all the rumours about China’s poor quality and cost reduction, and you may be afraid that if you place an order with a Chinese injection molding company, you will get substandard products.

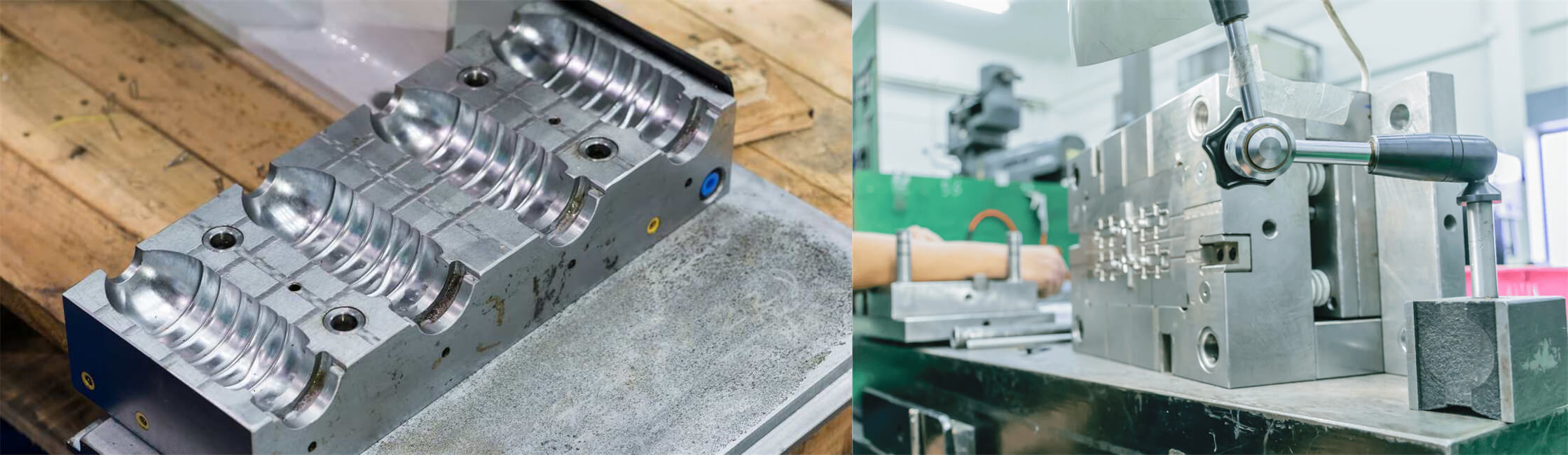

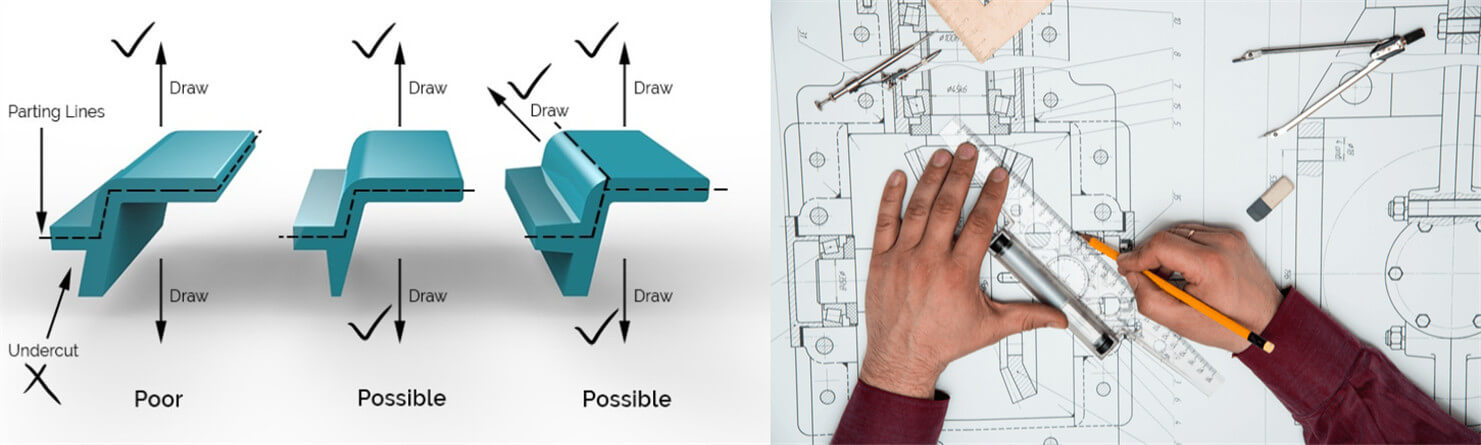

But how hard is it to do it well? If the design of an injection mold is correct and the expert drawings clearly specify all tolerances, including material, steel grade, hardness and surface finish requirements, then a plastic injection everywhere is capable of making mold.

Indeed, some injection molding companies have had problems in the past. Cost, it all boils down to the bottom line! The company is so focused on cutting costs that they turn a blind eye to the high-quality molds produced in China. So why all the hype, the Chinese are dishonest?

In any industry, you need to be cautious. You cannot generalize and say that the whole country is dishonest. Although it sounds impossible, it all comes down to communication, more precisely, the interruption of communication.

China prides itself on producing high-quality products with the best prices in the world, but if you don’t specify what kind of molds and materials you need, but just accept cheap prices, you will burn yourself.

The old saying goes: “Cheaper buys expensive.”

1. Know where to start

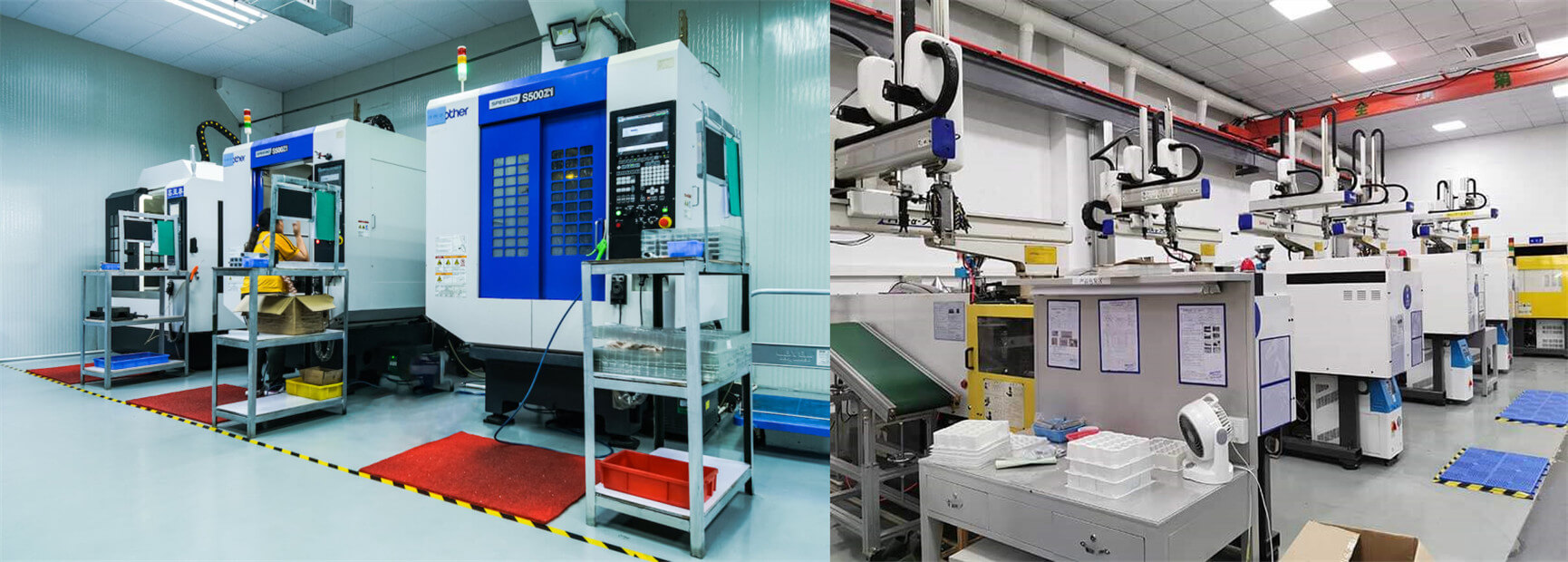

First of all, you must know that China produces high-quality molds every day. But you need to follow some “basic principles” to ensure that you get high-quality products at the right price.

You must clearly state your requirements and only work with Chinese injection molding company that you have reviewed. Your mold design drawings need to be point and drawn by professionals, there can be no room for error.

If you start your Chinese mold making communication and process with clear drawings, you have won 90% of the battle. Cost is the key, this is the bottom line, but business is business!

For a plastic injection molding manufacturer, if the price of the same plastic injection mold is 50% lower than that of its closest competitor, they must reduce the cost to less than 50% of the competitor’s.

This is usually reflected (or not reflected at all) in material selection, surface finish, material hardness, lack of precision grinding of mating surfaces, and lack of tight tolerances on the wall thickness of thin-walled products.

All these problems can be avoided by clear specifications during the inquiry stage. When specific specifications are required, obtaining quotes from Chinese injection molding company is difficult because the difference between quality mold makers (no matter what they are located in) becomes extremely small.

The total cost of ownership when outsourcing plastic injection molds should reflect all costs related to the testing and final acceptance of molds produced abroad, as well as additional preventive measures needed to ensure that technical errors are not caused due to language barriers.

There are many types of standard injection molding company in China. From the beginning, the most difficult thing is to choose the most suitable mold manufacturer for a company. This can be a tedious process, and sometimes the results can be somewhat mediocre.

Don’t despair!

Although it is relatively easy to find a trustworthy and well-known mold maker in Germany, Britain, Japan or the United States, it is not as difficult as you might think to find a trustworthy (reasonable price) mold maker in China.

In a previous blog, we discussed how to debunk the bad qualities of “Made in China” and outlined why the stigma surrounding this issue is often misunderstood.

But now let’s take a look at how to ensure world-class molds and ensure their safety.

2.100% ensure that you own the molds

If you ship the mold overseas, you will own the mold, but there are still some areas you need to be very clear with your Chinese mold manufacturer, such as full ownership, IP, and so on.

It is important to ensure that the mold maker understands that you are the owner of the physical mold if you are manufacturing in a factory in China.

First of all, you need to be clear that Chinese injection molding company can only use molds to produce your products, and they cannot use your molds or mold designs to produce any products for third parties.

Second, you need to make sure that if you want to move your molds to a different factory at any point in time, the receiving facility will have the right to take possession of the molds, and you can move them to a new location freely.

1) Why do they save your mold?

Chinese injection molding company have a strong incentive to save your molds and prevent foreign buyers from moving to new locations or factories.

In many cases, the model reflects most or all of the IP in the product. The internal mechanism of some products is entirely based on open-source hardware. Therefore, the outer casing surrounding the mechanism is the main protectable IP of the product.

The intellectual property is entirely in the mold used to manufacture the product shell. The external “appearance” of the shell becomes the ID of the product. If this “appearance” is not protected, you will have nothing in the IP of the product.

Without the protection of intellectual property rights in molds, Chinese injection molding company can copy products as they see fit. On the other hand, in some products, the form embodied in the mold holds the full value of the product.

An example might be a single component used in an extremely complex engine, such as a jet engine. After finishing all the design, engineering and testing, what are you left? A single part is produced by casting in one or more molds. In this case, the mold embodies all the intellectual property rights of this part.

In short, whoever owns or controls the IP of the mold is essentially complete control of the product, so you can see why this is a key aspect of mold manufacturing in China.

2)What happens if the IP is not defined?

If no one owns any IP in the model, then they are effectively classified as open-source, which means that no one owns any IP of the model or product, which is a terrible place.

Chinese injection molding companies have discovered this, which makes it very difficult to protect your mold. This means that when you draft an agreement with a mold manufacturer, you can’t just focus on ownership, but you must also consider the IP in the mold.

What can be done to avoid the trouble continuing? consult an expert and tell them that you do not need to repeat the work.

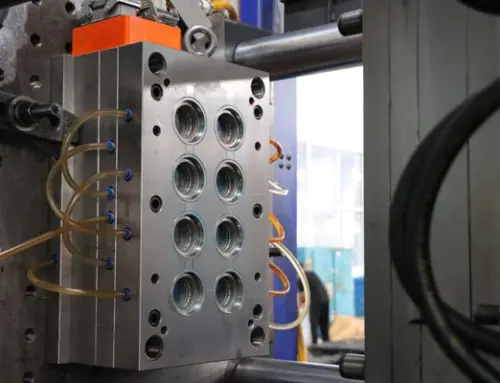

3. You or your trusted third party should attend the mold test

The quality of the pudding depends on it after it is eaten! Once the mold is manufactured, it must be properly tested, a report submitted, the results fed back, and most importantly, any errors or parameter failures need to be corrected.

To this end, the mold is installed on an injection molding machine of appropriate size, an optimized injection cycle is set, and a limited production run and all the parameters of the production intention operation are started.

This allows you to check the tool under real performance conditions, fine-tune its settings, and generate a complete discovery report, including points and tool modifications that need to be adjusted or improved, to provide trouble-free operation and provide the maximum life of the mold.

It is important that you or a representative of your company attend. In most cases, the third-party QC company has a track record of experience to attend and make recommendations on the results of the mold test.

You can’t give this to the manufacturer

In the final step of testing the mold, the difference between success and failure is measured in tiny millimetres. There is no substitute for experience in this regard.

Make sure you ask for the following from your mold maker

- Verifiable references

- Steel source and chemical analysis report

- The overall capital investment of the mold maker (this must be provided by the manufacturer, if the capital investment is weak, less than a few million, this will indicate that there is little time).

- A company’s online image is sometimes misleading

- Are they original equipment manufacturers or middlemen?

- Previous quality report (if any

- Quality System Guidelines

- Case studies of previous work

- Capabilities-whether they are outsourced or done internally

- The production capacity and delivery time on the date of placing the purchase order

We hope that the information in this blog will help you find the best injection molding company in China.

Leave A Comment