In order to obtain accurate product quantity and quality, you need a professional manufacturing company. An efficient manufacturing team uses various advanced technologies to ensure the smooth operation of other businesses.

The Chinese manufacturing process is also heavily reliant on Computer Numerical Control. In the CNC machining process, computers and computer programs are usually used to control machine tools, including routers, milling machines, and grinders. Let’s talk about several main parts of CNC machining in China

1. CNC milling

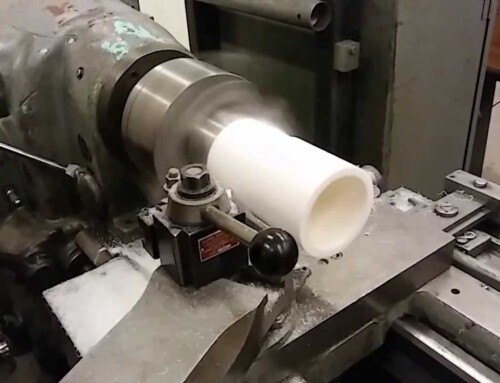

This is the most precise and efficient technology, including computer control and rotating multi-point cutting tools, to eliminate material in three dimensions at a faster speed, and to produce the desired product shape in an easy way. It can handle different types of materials, including plastics.

This process is fully applicable to a wide range of materials such as metal, plastic, glass and wood. It makes high-speed and custom milling possible and produces custom-designed parts and products according to requirements.

The CNC milling process has gone through the same stages as the CNC machining process, such as planning and designing the CAD model, converting the CAD model into a CNC program, planning the CNC milling machine, and executing the milling process.

2. Grind

CNC machining includes a surface grinder to help cut any amount of material, using a rotating wheel to make a high-quality flat surface to a tight tolerance. Ensure the accuracy and accuracy of parts production.

It is mainly used to develop the highest standard metal workpieces in the finishing process of camshafts, ball bearings, transmission shafts and other workpieces that require precise finishing. It can manufacture cylindrical workpieces and other types of workpieces.

However, this process must be performed by experienced and skilled technicians and a high level of computer control performance. We have the most skilled manpower to complete this job. This process is one of the most costly processes in mechanical processing, but the accuracy has been confirmed.

In addition to these processes, China’s CNC machining also includes turning, tapping and CNC cutting.

3. What is the profit of CNC machining in China?

Of course, there are different manufacturing processes that can be used to make parts or products, including manual processing. However, this kind of precision machining is one of the finest processes for machining complex-shaped parts according to customer requirements and expectations.

It integrates three-dimensional shapes that are essential in different manufacturing fields. Therefore, if you need to provide some complex parts for your business and customers, then you can outsource your next project to our professional team to achieve the results you want.

Compared with manual machining, this precision machining process eliminates errors and greatly reduces the workload. It is superior to the traditional manual nature because it ensures speed, productivity and accuracy.

You may find that the traditional cost is usually lower, but meets the requirements of small projects. At the same time, China’s CNC machining is mainly used for mass processing, and the cost may be relatively low.

Most importantly, this precision machining process can include a wide range of materials such as stainless steel, aluminium, iron, bronze, brass, standard silver, copper, carbon steel, titanium, acrylic polystyrene, and polycarbonate. You can add metals and hard plastics as well in this extensive list of materials.

4. Conclusion

Investing in CNC machining manufacturing processes to produce your parts or products may be a wise decision. You only need to hire a professional team to meet your requirements.

Holly is a leading company that provides various services to meet your manufacturing needs. We provide services at reasonable prices.

Leave A Comment