The design of many products involves some interaction with food. Containers, packaging, cans and bottles, kitchen utensils, machinery and electrical appliances can all directly or indirectly come into contact with edible items and then consume them.

It’s important to know what your food is made of, but it’s also important to know what the food-contact items such as packaging and utensils are. Some materials are toxic or degradable, so they are not suitable for close contact with food because they will eventually cause serious harm to consumers.

Therefore, companies that produce food need to consider many issues. They also need to use materials that are food-safe and legally recognized, as well as ones that are strong, durable, affordable and easily manufactured.

This article discusses the choice of materials (and limitations) when making food prototypes such as containers and kitchen utensils.

When developing food prototypes, researchers examined the differences between US and EU materials regulations and the processes used for making those prototypes (CNC machining, 3D printing).

1. Why must the material be food-safe?

Products that come into contact with food and beverages need to use specific materials, can not cause harm to the human body, can not change the state of the food in contact, can not interact with the food to lose integrity.

When inedible substances come into contact with food—for example, when a knife cuts through vegetables, or when milk is stored in a carton—the main concern is that the molecules of the inedible substance may end up in the food and then be eaten by people.

This transfer of molecules is called migration. When molecules of metals, plastics or other materials contaminate food, they can affect the taste or appearance of the food, or even worse, make eating dangerous.

Food safety materials tend to have low migration rates. The materials used for food also need to be sufficiently resistant to the food they will come into contact with.

For example, containers for high-acid beverages must have sufficient corrosion resistance, and microwave containers for frozen food must have heat-resistance so that they will not warp or break during use.

2. Which materials are safe for food?

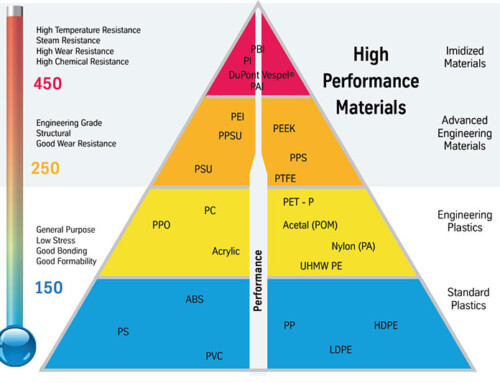

The suitability of certain food safety or food-grade materials depends on the end-use of the manufactured part. However, some materials are recognized standards in the industry.

Food safe metals include:

- Stainless steel 316: utensils, containers, machine parts

- 304 stainless steel: tableware

- Stainless steel 430: container, especially corrosive food

- Titanium: utensils, machine parts

- Cast iron: pots, pans

- Aluminium: canned food, bakeware

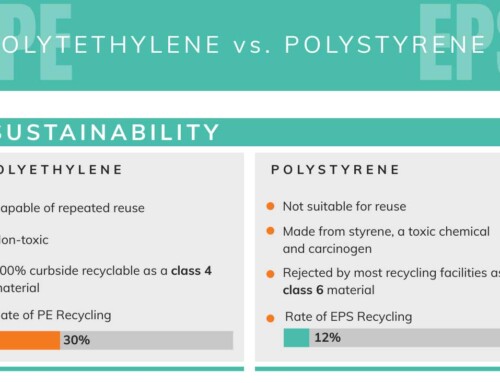

Food safe plastics include:

- HDPE: bottles, food packaging, food storage barrels

- LDPE: cling film/film, waterproof inner container, six-pack connector ring

- PET: bottles, jars, containers

- PP: yoghurt jar, disposable microwave container

3. What are the official regulations for food safety materials?

Food regulations vary from country to country, so it is important to review the rules and guidelines of the target market area.

In the United States, these regulations are handled by the Food and Drug Administration (FDA), which discusses food in a document called Indirect Food Additives: General Provisions.

The FDA emphasized the importance of “good manufacturing practices” and pointed out that “the purity of the substances used as ingredients of food-contact articles should be suitable for their intended use.”

In the European Union, regulations are provided by the European Food Safety Authority (EFSA). The EU stipulates that food contact materials (FCMs) “should be sufficiently inert so that their ingredients will neither adversely affect the health of consumers nor affect the quality of food.”

When preparing food for production, you should refer to these documents or documents from other countries.

4. What should you consider when making a food safety prototype?

It is important to remember that prototypes are not production, and prototypes are not subject to the same regulatory oversight as products released to the market.

In most cases, in order to test its performance during development, it is useful to create prototypes with food-grade materials (materials that will eventually be used in production).

If this is not possible, then similar materials should be considered. However, although there are practical benefits to using food-safe materials in the prototyping process, strict regulatory standards must be passed at every stage of the prototyping process.

For example, in the production process, all machinery used must comply with food regulatory standards, but this is not the case in the prototyping process, because the prototype will not be used by consumers.

This makes it possible to save a lot of costs in the prototyping process without affecting the practicality of the prototype.

The prototype may include the use of manufacturing equipment that has not been used in the production process.

Although it is more useful to closely match prototypes with their end-use counterparts, low-cost manufacturing processes may need to be used during the prototyping process, especially if only a small number of units are required.

5. What is the production process of the food safety prototype?

During the prototype stage of product development, you have several options to make a food-safe prototype. (Some of these options, such as 3D printing, become less feasible in production.)

- CNC machining: CNC machining centres can process almost all food-safe metals and plastics. Very suitable for kitchen utensils and non-disposable items.

- Metal Casting: Although more expensive than machining, casting can be used for iron frying pans and other heavy cooking utensils.

- Vacuum Casting: Vacuum casting uses silicone molds, which are food-safe, so they are ideal for small food containers and other plastic items.

- Injection Molding: Injection molding is the industry standard process for food safety materials (such as HDPE, LDPE, PET and PP). However, when ordering small batches of prototypes, it can be expensive.

- 3D Printing: 3D printing can be used to make some food-safe items, but the rough surface texture of the printed parts will cause gaps, and bacteria will multiply in the gaps.

- Sheet Metal Manufacturing: Food grade stainless steel, such as 304 and 316 are ideal materials for sheet metal manufacturing, so they can be made into bakeware, heavy restaurant equipment, and so on.

Holly has many years of experience in making prototypes for various customers. If you have any questions about food safety samples and materials, please contact us.

Leave A Comment