Fasteners play a vital role in part design, manufacturing and assembly. This small hardware is simple and cheap, but without them, it would be difficult for us to manufacture many important things: furniture, building structures, computers, floors, vehicles, and so on.

The function of the fastener is to mechanically connect two or more parts together. You can connect components in many ways, but the unique thing about fasteners is that they usually (though not always) create non-permanent connections.

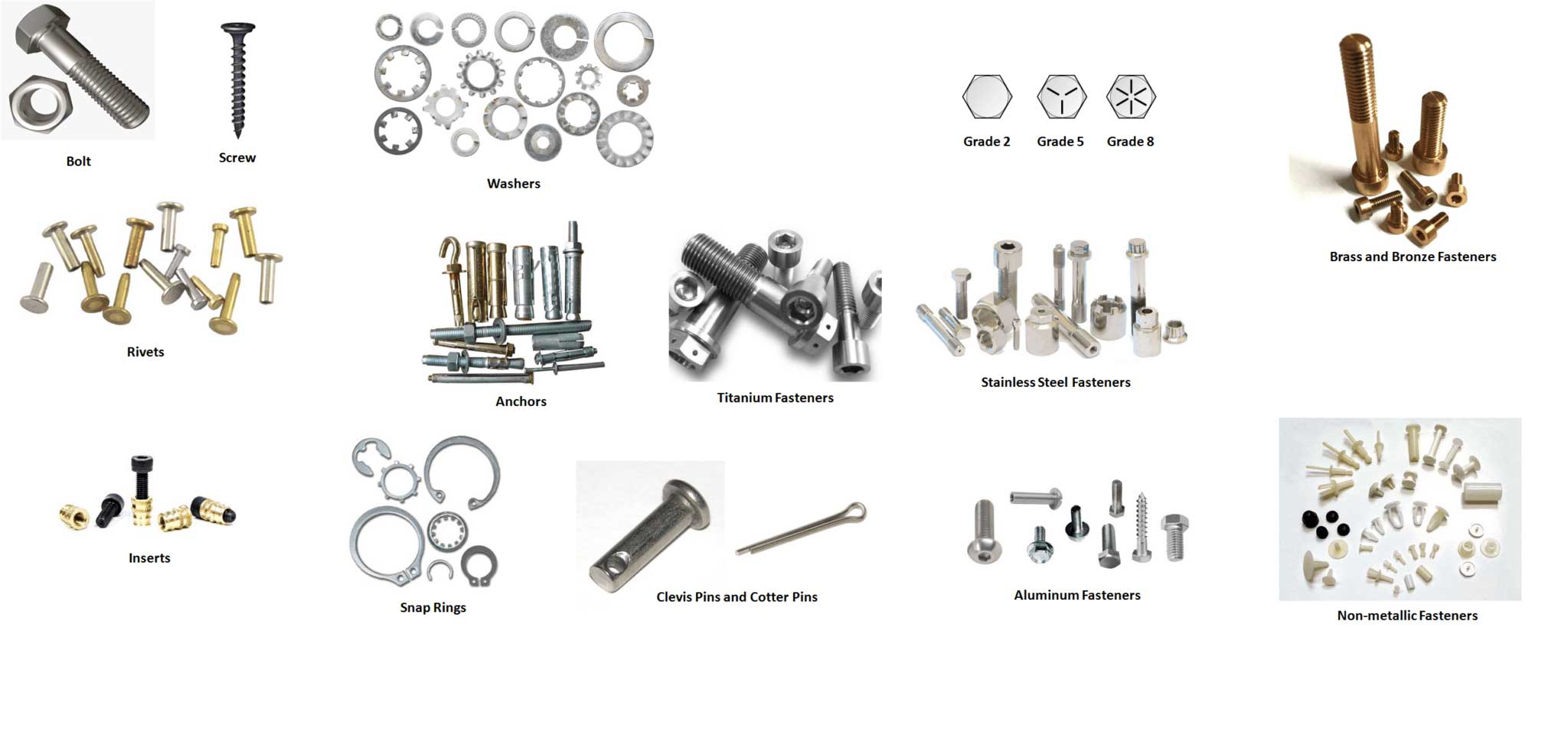

Fasteners are everywhere, and you will encounter many in daily life. Some of the most common types of industrial metal fasteners are:

- Screw

- Nut

- Bolt

- Rivet

- Threaded insert and rod

- Washer

However, the category of fasteners also includes non-industrial hardware, such as DIY nails and carpentry nails; Buttons, buckles and zippers for clothing; Household nails and cable ties; Office supplies such as staples, pins, and paper clips. All these types of fasteners work slightly differently, but they are all used to connect or assemble objects.

Metal fasteners are almost always made of steel (stainless steel, carbon steel, alloy steel), aluminium or titanium. Many of the parts we manufacture at Holly—including machined, molded, and sheet metal parts—are ultimately assembled using fasteners.

This guide details the different types of fasteners and explains how they work and how to use them. This may help our prototype customers who are developing multi-component products that need to be assembled with fasteners.

1. What are fasteners?

The fastener is a general term for a piece of hardware, usually made of metal (such as steel), used to mechanically connect two parts together. Fasteners, including screws, nuts, and bolts, usually cause non-permanent connections;

In other words, the connection can be undone without damaging any of the components. You can connect two components with one fastener, and then remove the fastener one day to separate the two components without damaging them. For example, a screwdriver may eventually be used to remove the screws;

In contrast, for example, welding, bonding or welding components: when this happens, the components are not easily separated. That being said, some fasteners, such as rivets, create permanent connections and are not designed to be untied.

Most fasteners are very small, and the diameter can be measured in millimetres. However, larger equipment may be used in areas such as shipbuilding, pipelines, and energy. The definition of a fastener is its function of mechanically connecting two or more components, not its size, material or application.

There are many different types of fasteners to choose from. Some of the most common industrial and manufacturing metal fasteners are listed below.

2. What are the fasteners made of?

The best materials for producing fasteners include steel (stainless steel, carbon steel, alloy steel), aluminium, titanium, copper, brass, nickel and various alloys. Commonly used stainless steels for industrial fasteners are 200, 300 and 400 series.

Fasteners can also be coated with other materials to increase functionality, such as corrosion resistance or electrical insulation. Common coatings and platings include chromium and zinc.

Different types of industrial fasteners are used for different materials, and some fasteners are designed for one material, namely wood screws (wood) or anchor bolts (concrete).

1) Fastener standards

The American Society of Mechanical Engineers (ASME) currently has 66 current published standards under the fastener B18 index. The quality-centric standard “establishes the process and final inspection requirements for fastener products” and provides a “receipt inspection plan for fastener buyers”.

ASME standards include:

- 1.1: small rivets

- 1.2: Big rivet

- 2.3.1 m: Metric hexagonal cap screws

- 3 Hexagon socket cap, shoulder, set screw and hexagon socket key

- 6.1 wood screws

- 6.2 slotted head cap screws, a square head fixing screws and slotted headless fixing screws

- 6.3 machine screws, self-tapping screws and metal drive screws

- 6.9: Wingnut

- 18 fastener quality assurance

2) Screw

Threaded fasteners are usually made of metal and are fasteners with external threads (helical ridges) that engage with the internal threads of the fastener component. A typical feature of screws is that they are usually self-threaded or self-tapping: they have a sharp end that cuts into the surface of the component;

When the spiral rotates, it cuts the internal thread into the assembly and allows a connection to be made. Screws are usually independent fasteners because they are connected to the component itself.

The function of a screw is similar to that of a bolt, but the bolt is usually not self-threaded; Their tips are usually blunt, and the bus bars in the assembly must be made by other methods. However, it is confusing that some fasteners, which are technically screws, are labelled as bolts (and vice versa) through use.

Type of screw

There are many different types of screws suitable for different applications. There are several types of screws:

- Sheet metal screws: very sharp self-threaded screws that can penetrate sheet metal, wood and plastic.

- The machine screw is widely used for machine parts and installed in the predrilled hole. It has precisely fine threads and is installed in the predrilled hole.

- Cover screws: large-head screws, usually used for mechanical assemblies, such as electrical appliances.

- Eyed screw: This type of screw is sometimes called a lagging eyed screw. This type of screw has a round head through which thread can be threaded.

- Lag Screw: Long galvanized screw, mainly used for woodworking.

- Wood screws: commonly pointed screws used in woodworking.

Screw drive type

Screws can also be classified according to their drive design: different tools are needed to drive or remove different screws. Screw drive types include:

- There are slots

- Trident

- Cross (e.g. Phillips)

- Outer polygon

- Internal polygons (such as internal hexagon / internal hexagon)

- Hexalobular

3) Bolt

Like screws, bolts are fasteners with external threads that are used to connect two or more components. However, unlike screws, bolts require a preformed internal thread to engage. They are not self-threaded;

On the contrary, bus bars are usually nuts. Bolts (external threads) and nuts (internal threads) are used to connect parts with unthreaded holes. This kind of connection is called a bolt connection.

When used with nuts, bolt fasteners use through holes (that is, holes that penetrate the material of the object), with the bolt head on one side and the nut on the other side.

On the other hand, screws are often used to make blind holes; They can only partially penetrate the material.

Type of bolt

There are many different types of bolts suitable for different applications. The most common types of bolts are:

- Hexagonal bolts: Hexagonal threaded bolts, there may be non-threaded parts directly under the head.

- Sexual bolts: Sometimes called Chicago bolts, tubular bolts or tubular nuts, these bolts are actually bolts and nuts at the same time, including an internally threaded tubular screw and an externally threaded screw.

- U-bolt: U-shaped fastener with two parallel threaded ends, used to fix pipes and other projects.

- Bolt with ring: A bolt with a ring head that can be threaded through.

- Carriage bolts: threaded bolts with round mushroom heads to prevent turning, and are attached to the square neck immediately below.

4) Nut

Nuts are fasteners with internally threaded holes and are usually used together with corresponding bolts to form a bolt connection. Nuts and bolts cooperate with the work of the system to connect components with unthreaded holes.

Nuts and bolts are usually kept safe due to friction, compression, and slight tension of the bolt. However, in the application of high-intensity vibration, the joint may become loose.

In this case, a lock nut or lock fluid can be used to secure the nut, or a second nut can be added to the bolt. Although the inside of the nut is threaded, the outside can take many forms, depending on whether it is rotated by hand or with a wrench, and various other factors.

Type of nut

There are many different types of nuts suitable for different applications. The most common nut types are:

- Acorn nuts: Sometimes called cap nuts, these fasteners are semi-circular to cover one end of the bolt.

- Welding nut: One end of the design can be welded to another metal component.

- Hexagonal nut: Ordinary fastener with the hexagonal surface, easy to wrench.

- Wingnut: There are wing-shaped nuts on each side, no tools are needed, and it is easy to rotate manually.

- Barrel Nut: See “Sex Bolt” above.

5) Rivet

A rivet is a type of fastener, usually with a smooth shaft and no threads. A rivet has a head at one end and a tail at the other end.

In order to play the role of a fastener, a rivet is put into a hole, and then the tail is “turned” by mechanical force to expand it to about 1.5 times the diameter of the shaft to form a connection.

Once a rivet is broken, it actually has two heads: the original factory head and the new workshop head. Unlike screws, threads and bolts, rivets create a permanent connection: once the tail is damaged, it cannot be restored to its original state.

Therefore, riveted joints are more difficult to separate than non-permanent joints such as bolted joints.

Type of rivet

There are many different types of rivets suitable for different applications. The most common types of rivets are:

- Hollow rivets: Also known as blind rivets, these rivet fasteners are tubular, have a central mandrel, and a weak area near the head (where it can be broken).

- Solid rivets: simple fasteners with shafts and heads, which can be deformed with a rivet gun or hammer.

- Semi-hollow rivets: similar to solid rivets, but with a partial hole at the top, which can reduce the force required for upsetting.

6) Mixed Threaded fasteners

In addition to screws, bolts and nuts, there are other threaded fasteners with more special uses.

A threaded insert (or threaded bushing) is a fastener with internal (and sometimes external) threads that are inserted into materials that normally cannot accept threads-either because it is too soft or because of existing threaded holes Was stripped off.

It is like a gypsum board anchor used to build a shelf. The metal threaded insert can be mounted on the molded part by molding around the bushing. A threaded rod (or stud) is a fastener similar to a bolt, but with threads at both ends and no head. Designed for tension, threaded rods can accept nuts at both ends.

7) Washer

Although technically speaking, the washer itself is not a fastener, it is a hardware component used with fasteners such as nuts and bolts. A washer is a thin plate with a hole in the centre and is used as a gasket, load distributor, locking device, or shock absorber.

The gasket is usually round, but it can also be square. The gasket prevents the fastener from directly contacting the component, thereby protecting the surface of the component.

nice post shared.