Chinese CNC Machining Services are a popular choice for companies seeking outsourced machining services because they promise low costs and fast turnaround. In fact, CNC machining in China is a crucial step for many product developers, because few countries can compare with China in terms of cost and efficiency. Having said that, in terms of CNC machining, China may be difficult to control.

There are many CNC machining companies to choose from in China, and communication may be more challenging than communicating with the domestic supply chain—not to mention differences in currencies, standards, and intellectual property laws.

In order to make the lives of potential customers of China’s CNC machining services easier, this article provides advice on how to order CNC machining parts from China, observes the outsourcing process in Asia, and points out common pitfalls that may be encountered.

1. Outsource CNC machining to experts

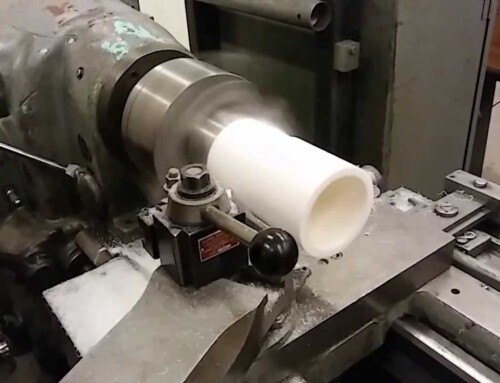

Hardware companies large and small tend to outsource their CNC machining needs to experts. Even for prototypes, it usually makes sense to use a third-party CNC machining company instead of an in-house solution due to the factory space and the human skills required to operate the processing equipment.

Here, the nature of CNC machining technology and equipment is a big factor. Unlike desktop 3D printers, CNC machine tools take up space and require a safe factory environment. Their raw materials are large heavy metal (or plastic) blanks instead of pocket-sized 3D printer filament spools.

For small and medium-sized enterprises, whether or not they have skilled processing workers, it is usually meaningless to invest in in-house CNC processing equipment.

Skilled machining workers are also hard to find. Although CNC machining may not be as good as the art of manual machining, it still requires a lot of knowledge and experience to prepare and execute the machining work.

Parts made from one grade of aluminium may require a completely different set of processing parameters to make parts of another grade.

2. Why Choose China CNC Machining?

In the past 20 years, Chinese manufacturers have greatly increased their adoption of CNC machining equipment, and have therefore become the preferred solution for hardware companies around the world. China has always been one of the most competitive manufacturing industries in the world, and the increase in CNC machining suppliers has further reduced costs.

For their CNC processing, Chinese companies may use Chinese-made equipment or Western equipment, or a combination of the two, and most will provide their equipment list requirements. In recent years, there has been an increase in processing options in neighbouring countries such as Vietnam and Taiwan, where labour costs are lower, but Chinese companies usually provide better results.

This is partly because the development of Chinese CNC companies is more mature, but also because mainland China has better supply chain and logistics options.

However, CNC machining only makes sense in certain circumstances in China. For example, if a company needs a heavy and simple part, it may make more sense to order from a local manufacturer, as shipping may significantly increase the total cost of ordering from China.

In addition, since the good value of CNC machining in China comes from low labour costs, it is meaningless to use Chinese manufacturers if labour costs are not involved. For example, the large-scale manufacturing of a part (more than 100,000 pieces) may require robot automation, thereby completely avoiding labour costs, so the price in the western region will be similar.

3. Find a CNC machining company in China

It seems difficult to find a suitable Chinese CNC machining company, but some steps can be taken before choosing a partner. Certification is a method of assessing the suitability of a company. ISO certification is a good guideline for identifying qualified CNC machining companies, although they will not tell you the company’s range of capabilities. Word of mouth is another effective way to build a candidate list of potential Chinese CNC companies.

Talk to other hardware companies in the region that have signed contracts with manufacturers to learn about their experience in working with third parties. Before making a decision, the shortlisted companies need to provide information. Once you have established a point of contact, continue to ask questions until you are satisfied that the company knows how to execute your project.

If they cannot give you a clear answer, they may not be a suitable partner. If possible, visit the factory. This may not be feasible for small companies, but visiting Chinese CNC machining facilities may be the best way to assess which companies are best for a project.

In some cases, a manufacturing agent can be hired to arrange visits to multiple locations in a given area. Send an inquiry to find out how much a company will charge. You don’t need to reserve a quotation request for the company you ultimately choose. If you send an inquiry to several shortlisted Chinese CNC processing companies, you will know who can provide the best price.

4. Things to remember when ordering CNC machined parts from China

Ordering CNC machining projects from China shouldn’t make much difference if you have used domestic contractors in the past. However, there are some unique considerations to keep in mind.

1) Use common standards for communication

Ideally, you would want to cooperate with CNC machining experts in China, such as Holly, whose employees can easily communicate in English. However, translation problems also arise. In order to alleviate this problem, please be sure to submit a complete technical drawing and your digital file to eliminate any ambiguity.

2) Ask your partners to sign a non-disclosure agreement

Intellectual property rights make many customers afraid of cooperating with Chinese manufacturers. Although the intellectual property law is gradually changing, it is a good practice to sign a non-disclosure agreement (NDA) with a CNC processing company to legally prevent the company from disclosing or reusing your design.

3) Consider shipping time

For prototypes and small-batch orders, Chinese companies can usually use priority airmail and deliver them within a few days. For larger quantities and larger parts, shipping services may be required, which may result in longer waiting times than domestic orders. If you have a tight deadline, be sure to discuss the shipping time with the manufacturer.

4) Consider currency exchange factors, if applicable

Most Chinese CNC machining companies will accept payments in various currencies, including U.S. dollars, but if sending international wire transfers, additional fees may still be involved.

If you have any concerns, please discuss the situation with the manufacturer and your bank. Holly is one of the most trusted CNC machining service providers in China, suitable for projects of all sizes. Contact for a free quote.

Leave A Comment