When you entrust an injection molded product to a manufacturer, you enter a partnership. It is reasonable to say that you want your manufacturer to always meet your expectations, provide timely output, and add value to your project. However, if you find yourself in an unbalanced partnership that has eroded your confidence in them through poor quality parts production, unfinished orders, or other annoying activities, then it’s time to look for business elsewhere. Up. But first, you need to know what to look for in an injection molding manufacturer.

1. Appropriate Injection Molding Certification

Considering how important it is to meet the standards of plastic parts in areas such as the medical industry, the injection molding industry has strict guidelines. In particular, the following are the certifications that manufacturers should have:

Design and production certification: IQ/OQ/PQ process verification controls the quality standards of the manufacturer’s equipment. In addition, having documented design software training, such as SolidWorks CAD, is essential to determine their prototype proficiency.

Quality control and assessment certification: The most common type of certification is the ISO series certification-we comply with the current ISO 9001:2015. This is an important certification for manufacturers because it means a proper quality management system.

Material safety and procurement certification: In some industries, such as the medical field, traceability is very important. It is important to ensure that manufacturers have a documented understanding of domestic and foreign laws and ethics, just like our conflict minerals policy.

Looking for certifications under these categories will tell you how reliable the manufacturer’s quality control and commitment to industry standards are.

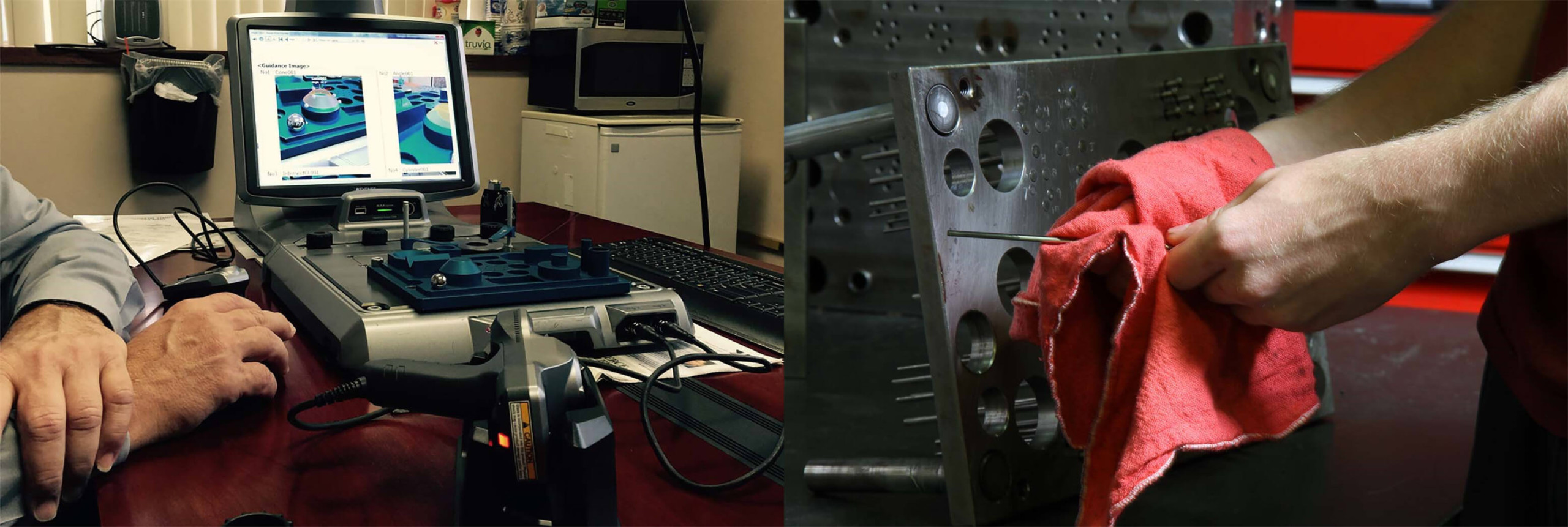

2. Manufacturer Quality Control Level

Since the stability of plastic injection molding requires incredible precision, your manufacturer should have a library of quality control and safety measures integrated into their process. A good way to determine the manufacturer’s attention to detail is to see if they work with a range of thermoplastics and if they work in various high-precision markets such as medical, life sciences, and electronics. It is wise to have any potential partners describe their quality control practices in detail.

3. Shown Internal Mold Tools

Internal tools improve quality and production lead time, while also reducing the time, effort, and capital required for pre-planning and rework. This proves that the company is committed to meeting the investor’s design specifications, and it also allows your engineers to track the entire development phase. Especially considering the data shown by this year’s return index and the US-China trade war, due to the flexibility and the drastically shortened supply chain, it is more advantageous for companies to pursue internal processing than offshore processing.

4. Diversity of the Service Market

The diversity of the market is not only a good indicator of quality control but also means the stability and success of the enterprise. Sometimes, you may want to find an injection molding manufacturer that only focuses on your industry, however, it will limit their client base and cause their business to fail if they lose a major partner. Once the manufacturer goes bankrupt, you will no longer have a supplier. In addition, a manufacturer involved in a range of markets shows their extensive expertise that can lead to creative solutions.

Deciding what to look for in an injection molding manufacturer will ensure that your business is protected from unpredictable interruptions. Since your business depends on investing in a reliable component supplier, you should ensure in-depth negotiations with any potential manufacturers. If you need a company that meets all the criteria listed here, then Holly Mold is your best choice. If you are interested in learning about all the services we provide-from prototyping to production-don’t hesitate to contact us today.

Leave A Comment