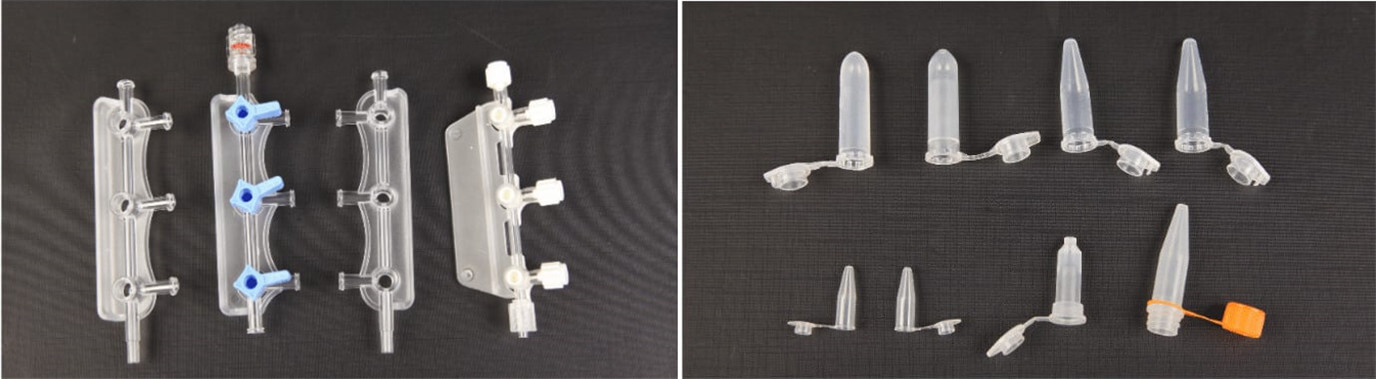

Medical parts play a critical role in numerous medical applications, and injection molded parts are one of the most widely used plastic parts. In view of the extremely strict requirements for hygiene and cleanliness of some medical injection molding products, clean rooms must be used for injection molding. The precision, thinning and high productivity requirements of medical injection molding products pose challenges to production units such as injection molding machines. . Molds and robots and the interaction between them.

1. What is the medical part?

To adapt to the development of medical technology, the medical plastic parts industry can develop rapidly. At present, there are thousands of medical plastic parts all over the world, and the technical content of the products is getting higher and higher.

At the same time, higher requirements are put forward for medical plastic materials; plastic parts generally used for disease diagnosis, treatment, monitoring, health care, and rehabilitation are called medical plastic parts. At present, medical components are widely used in hospitals, laboratories, scientific research institutes, etc.

2. What is the purpose of medical parts?

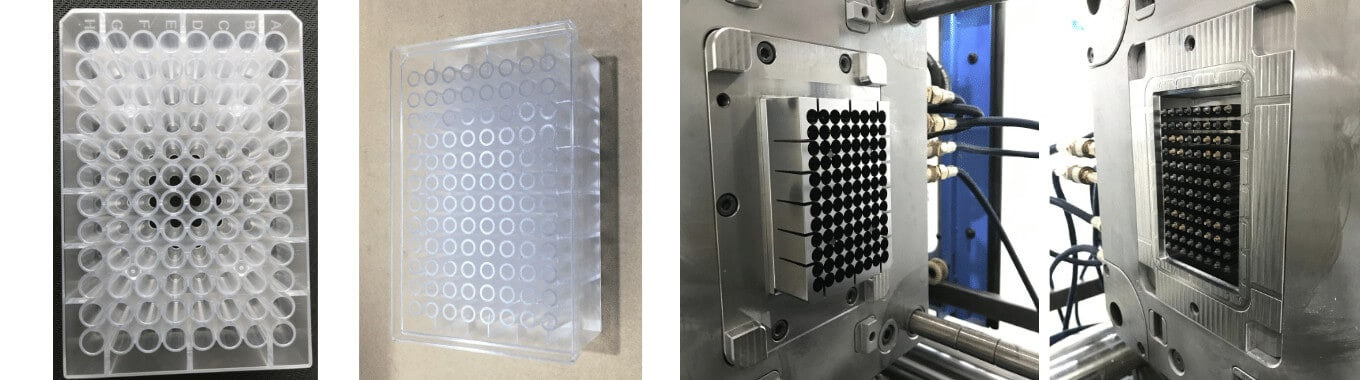

Medical components are widely used in hospitals, laboratories, schools and research institutions. Commonly used medical plastic products include:

- Test tubes and other containers

- Auto-injectors syringes, syringes

- Medical and laboratory equipment housing

- Surgical equipment and parts

- Drug delivery equipment and components

- Orthopedic implants

- Pipetting instrument

- Laboratory supplies

3. What is the material of the medical part?

There are many different types of materials that can be used to manufacture medical parts, here Holly summary of some common materials for your reference.

- PVC polyvinyl chloride.

The raw material of PVC is brittle, hard, and random. According to different applications, different additives can be added to give PVC parts different physical and mechanical properties. By adding an appropriate amount of plasticizer to the PVC resin, various hard, soft and transparent products can be made.

- Polyethylene

PE has high impact strength, low friction, resistance to stress cracking, and good energy absorption performance.

- Polypropylene, polypropylene

PVC is a type of thermoplastic that performs well. It has the advantages of low specific gravity, non-toxicity, easy processing, impact resistance and bending resistance.

- PS, polystyrene

Lightweight, transparent, and good processing characteristics are PS’ main characteristics.

- ABS, acrylonitrile butadiene styrene copolymer

ABS has the characteristics of hardness, hardness, impact resistance, chemical resistance, radiation resistance, and ethylene oxide sterilization resistance.

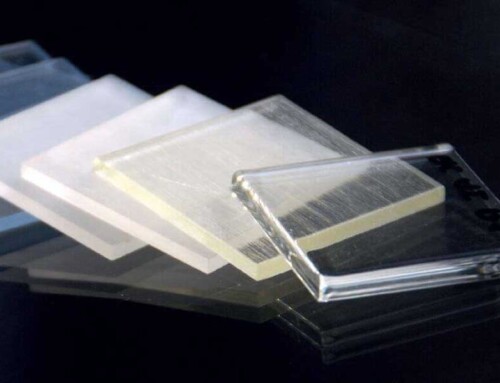

- PC, PC (polycarbonate) plastic

The typical properties of PC are toughness, strength, rigidity and heat-resistant steam sterilization.

- PTFE (polytetrafluoroethylene)

PTFE has the lowest coefficient of friction of any plastic and biocompatibility.

4. Medical Parts Features

The basic requirements of medical plastics are chemical stability and biological safety due to contact with drugs or the human body. The components of plastic materials will not precipitate into drugs or the human body, nor will they cause toxicity or damage to tissues or organs. Since each material has unique properties that determine the performance of the product in the application, it is very important to choose the right plastic material for your medical components.

- It has good tensile, flexural, compressive, and impact resistance, and can be used alone as a structural material.

- Chemical and heat resistance. When choosing medical plastic materials, chemical resistance and heat resistance are two key considerations, especially if your medical product must be able to withstand autoclaves and sterilization methods.

- Strength and corrosion resistance. If the medical product will be exposed to radiation, then the selected plastic material needs to be able to withstand the operating environment.

- The low friction coefficient and good biocompatibility, especially suitable for molding medical inserts and other plastic products intended to be used on the human body.

Holly has extensive experience to help and ensure that you use the correct plastic materials for your medical products. We will consider your product performance and provide you with expert opinions to ensure that the final product meets your requirements.

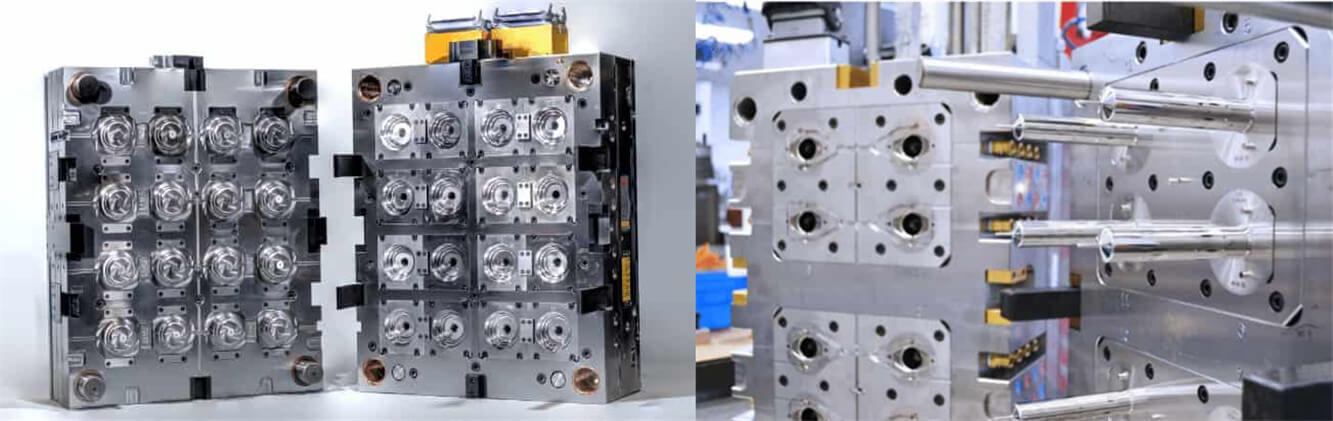

5. What is the commonly used steel for making medical molds?

The base of the medical mold adopts high-strength mold materials, including 420H, P20, etc.;

Lightweight, transparent, and good processing characteristics are PS’ main characteristics. And so on; and let a professional heat treatment company heat the main part of the medical mold, and the material hardness is generally above HRC48-52.

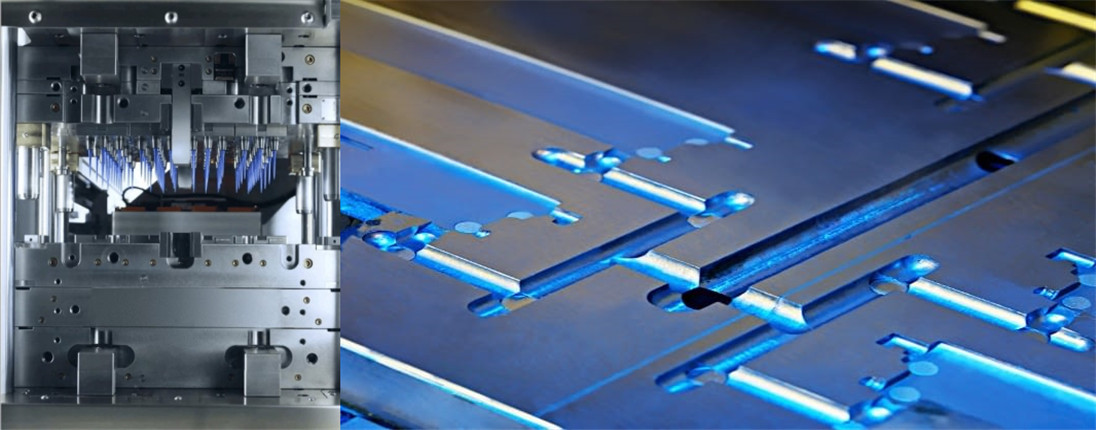

6. What is the focus of medical mold design?

1) Use hot runners for transparent products to reduce merging traces.

2) When using cold runners, soft PVC should be used to shorten the runner size as much as possible.

3) Medical products are typically small in size and produced in large quantities, which means automatic unloading and gate cutting will ensure production efficiency and quality.

4) The transparent tubular part, the position that should be paid attention to in the design, the way the door feed and the dynamic model Z are fixed, to avoid the correct selection of the door position and fixing method of the core, resulting in uneven filling in the injection molding, resulting in inelastic deformation of the core, The product will be an uneven and short lens.

5) Pay attention to the proper exhaust methods for tubular products to avoid forming difficulties due to gas accumulation.

6) The cooling system should adopt multiple separate cooling channels to reasonably control the temperature of the cavity and core to avoid product deformation.

7. What is the key to producing medical parts?

1) The injection molding workshop should be fully enclosed, and high-power air conditioners should be installed to ensure a constant temperature and clean air in the workshop.

2) It is strictly forbidden to use mold release agents and rust removers during the injection molding process to ensure that medical parts are not contaminated.

3) During the production process, the melting temperature should be strictly controlled to avoid excessively high material temperature to produce harmful gas, and stay in the barrel for a long time to decompose the raw material.

4) Clean the screw and barrel immediately after shutdown to avoid damage to the screw caused by residual raw materials.

5) Strictly implement the IS0 9000 quality management system to ensure that no problems occur during the production process.

8. What are the defects of medical parts?

Cracks, sink marks, surface ripples, surface delamination, welds, short shots, warpage, burn marks, jets, flashes, bubbles, shrinkage, warpage, delamination, peeling, etc.

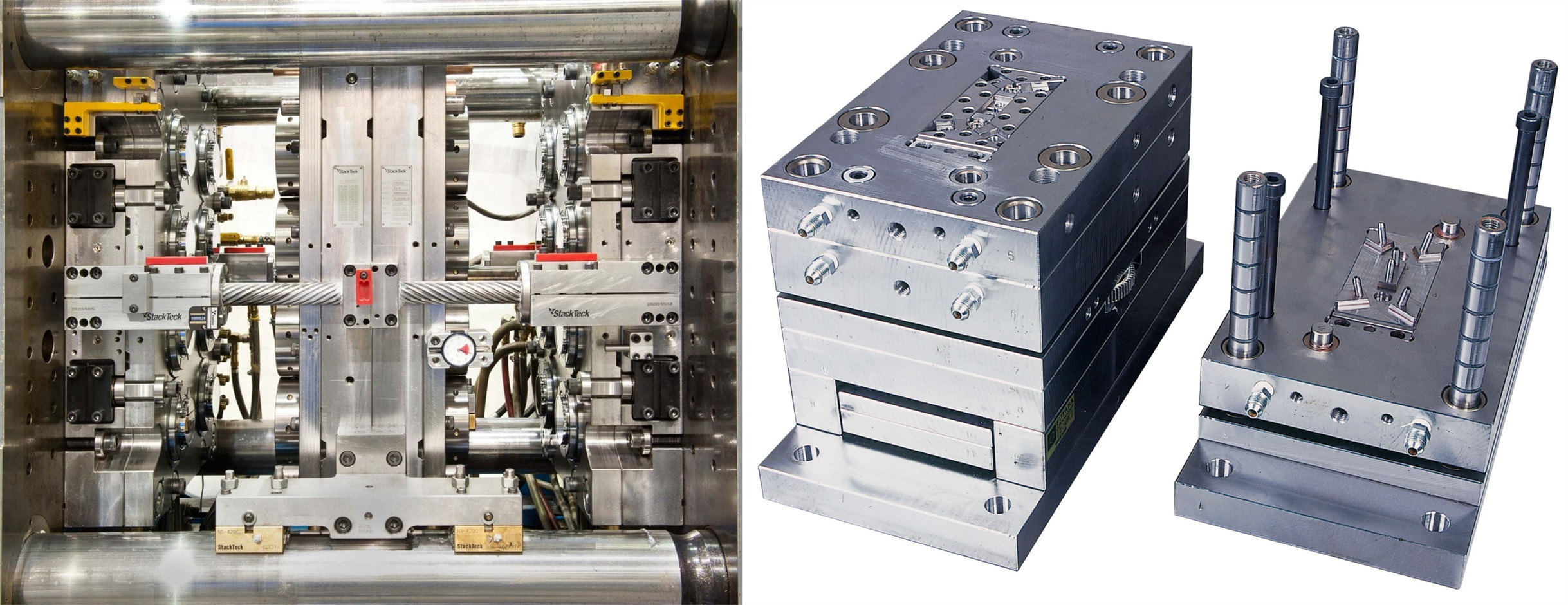

9. What is the difference between medical mold and common mold?

1) Medical injection molds operate in a clean environment, so the material selection is very strict. First of all, the mold material stainless steel materials need to be matched with surface treatments, such as vacuum heat treatment, PVD coating, laser heat treatment, etc. …

2) The medical part of plastic materials often has medical grade PP, PVC, ABS, public institutions, POM, PA, etc., with high strength, corrosiveness, wear-resistance and high transparency, etc., so the requirements of injection molds are relatively High, the choice of commonly used mold steel imports S136, 2316, S136H, NAK80… etc., to meet high corrosion resistance, high polishing.

3) There are also many differences in the structural design of medical molds. Many medical products are transparent in colour. The products should choose hot runners as much as possible to reduce the traces of dissolution.

4) The manufacturing precision of medical molds is higher, and medical-related injection products are absolutely not allowed to have any burrs. This requires extremely high processing accuracy of mold cores, and the processing accuracy of some cores is required to be less than 0.005mm.

5) It is crucial to ensure that medical molds are manufactured in a cleanroom since the injection molding environment is harsh.

Generally speaking, there is not much difference in structure between medical molds and ordinary molds, mainly in the control of processing technology and processing accuracy.

10. What services can Holly provide for my medical organs?

Holly can provide a one-stop service for your medical parts.

This includes:

- New product development and design;

- Design Review (DFM/mold flow analysis, tolerance analysis, feasibility study);

- 3D printing or prototype mold;

- Mold manufacturing;

- Cleanroom, all-weather production and operation;

- Product assembly and packaging

- Mold maintenance.

- Technical support and service.

Holly offers competitive prices and uses the most advanced equipment and methods. We have passed the iso9001:2015 certification. If you have any medical accessories items, please feel free to contact us, we will turn your product from an idea into a reality.

11. Why do medical parts fail to function properly in short shots?

- Choose plastic materials with lower viscosity and higher fluidity;

- Increase the temperature of the barrel, nozzle and mold to increase fluidity;

- Increase the feed volume of the molding machine;

- Choose an injection molding machine with a larger injection volume;

- The runner and gate are too small, so appropriately increase the gate size;

- Increase the injection pressure;

- Increase injection speed;

- Improve the mold design and appropriately increase ventilation.

12. How to improve the quality of medical molds?

1) First of all, the design of medical molds must choose the best structural plan. The designer must consider the technical requirements, and its structure must meet the manufacturability and feasibility of the mold.

2) The selection of medical mold materials must meet the customer’s requirements for product quality, while also taking into account the cost of the material and the sufficient strength and rigidity of the mold.

3) The processing method and processing accuracy of the medical mold in the manufacturing process will also affect the life of the mold. In order to ensure that the mold has good accuracy, in the manufacturing process, firstly select high-precision processing methods, and secondly, strengthen the surface of the main parts of the mold to improve the wear resistance, so as to better improve the quality of the mold.

4) The correct use and regular maintenance of medical molds can prevent possible problems during the production process and increase the service life of the molds. This is also an important factor in improving mold quality.

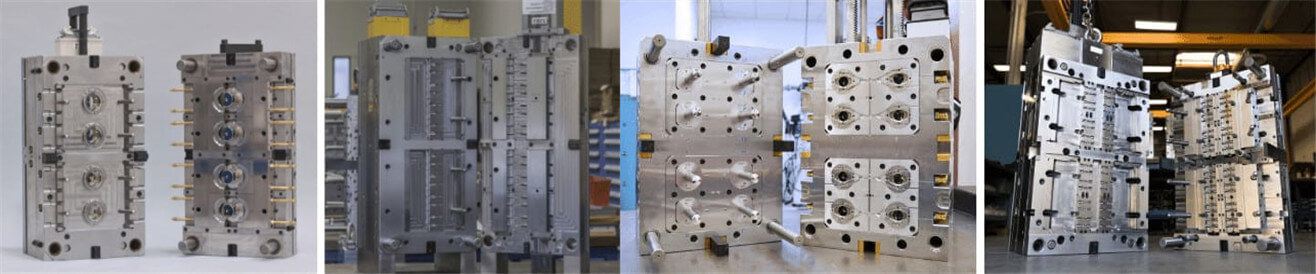

13. How to choose a medical mold injection machine?

For medical products without special cleanliness requirements, such as fitness equipment products, general injection molding machines can be used. It is recommended to use clean room-compliant injection molding machines and peripheral equipment when making medical products that require a cleanroom environment for production.

For example, for the production of injection syringes, due to the high requirements for appearance and size, a machine with precise control and suitable for multi-cavity thin shell molding should be selected; if it is to manufacture medical electronic equipment, in addition to the stability of the machine, it must Consider whether auxiliary equipment can meet the requirements accurately and efficiently;

Holly has injection molding machines ranging from 25T to 220T, and the injection molding environment includes a 7-level cleanroom injection molding workshop, which provides good conditions for the realization of customers’ products. The injection molding service we can provide you is.

- Mold test.

- Single color injection

- Micro product injection molding

Our engineers and technicians use rigorous methods to conduct scientific and thorough injection molding process tests on the molds to maintain a stable production process.

14. How to put the medical mold into the injection molding machine for inspection?

1) Scrub the dust, oil and rust on the appearance of the medical mold, remove the dirt on the appearance, and then put it into the injection molding machine.

2) Use an air gun or rag, detergent or alcohol (alcohol for mirror medical molds) to clean up the oil and dirt on the surface of the medical mold.

3) Check whether there is any foreign matter in the cooling water channel of the medical mold to ensure that the cooling water is unblocked.

4) Check whether the arc in the sprue sleeve of the medical mold is damaged, if necessary, whether there is any foreign matter remaining.

5) Movable parts: whether there is rust, bend, or broken, such as ejector pins, tension springs, hydraulic cylinders, sliders, etc., and whether they are smooth if necessary for movement.

15. How to maintain the medical mold after production?

1) Check whether each part of the medical mold is damaged.

2) Clean up oil stains on the parting surface and debris remaining in the mold cavity, and spray anti-rust oil.

3) Dry the remaining water on the cooling water channel.

Warm reminder:

Labour protection must be worn when maintaining medical molds. Overweight objects need to be operated by cranes. It is strictly forbidden to lift medical molds by hand to avoid injury to limbs.

To prevent the medical mold from rusting, pay special attention to the anti-rust effect of the medical mold after the maintenance of the medical mold, and use an air gun to blow dry the remaining water in the waterway.

Adding too much smoothing oil will not bring a better smoothing effect, just a moderate amount. After the medical mold is made, pay attention to the number and direction of the inserts and other parts and do not install them incorrectly, check whether the screws are used up, and lock the screws diagonally during installation.

16. How to choose a partner for medical injection molding?

1) First, it must be a suitable cleanroom class.

Generally, the capacity of Class 8 cleanroom is required. If there is a Class 7 cleanroom, this is a high standard. Holly has a Class 7 cleanroom that can meet any of your medical product requirements.

(2) You can mold, assemble and pack your products in a cleanroom environment.

If your medical parts can be molded, assembled and packaged in a cleanroom environment, there is no doubt that this will ensure the cleanliness of your medical products. Holly is equipped with a vacuum bag sealing machine to solve any problems you may have

3) Cleanroom modelling maintains close parts tolerances.

Mold manufacturers who can guarantee strict tolerances for medical products must have the expertise and experience to do so. Holly has more than 20 years of experience in making molds for well-known European brands and has professional knowledge and experience to ensure that every part is of high quality, not just clean.

17. How does Holly guarantee the quality of medical injection molding?

Holly has a Class 7 clean injection room. Every step is scientifically managed. As follows.

- The 7-type injection chamber adopts positive airflow, strictly controls the number of particles to ensure air purity.

- In Class 7 cleanroom, technicians and operators are required to cover their entire body when entering the cleanroom, and disassembly is not allowed during the entire operation.

- The electric machine can avoid more particles in the air.

- Scientific injection molding and mechanized data ensure accurate product tolerances.

- Machines that seal vacuum bags to prevent dust from getting into the product.

18. How does Holly Manage a Medical Project?

In general, we perform the following professional steps to manage your medical project:

1) The procedure begins after receiving an official order;

2) Evaluate your technical parameters and standard requirements;

- DFM analysis;

- After getting the approval of DFM, carry out mold design;

- After the mold design is approved, start ordering steel;

- Steel processing and mold manufacturing;

- Do T1 trial mode and check the report with QC;

- Ship T1 samples to you for confirmation;

- We will improve the medical parts and molds until we get your consent.

- The mold is shipped out until you get your confirmation.

- Mold performance tracking.

- Lifetime technical support and service.

As a professional medical mold manufacturer, Holly has developed a complete set of medical mold design and manufacturing processes after years of experience. Every detail of the design has been carefully analyzed and certified by professional designers. Your entire medical project will be handled by our experienced project manager. We always insist on making the most professional medical molds and give you the most worry-free service.

19. Why should I find a medical mold manufacturer in China?

Looking for a mold manufacturer that can guarantee the quality of your medical products, and at the same time provide competitive prices, can help your products gain market advantages.

The industrial structure of my country’s medical mold industry, whether it is enterprise organizational structure, product structure, technical structure, import and export structure, is developing in the direction of rationalization, and mold products are developing in the direction of large-scale, precise, complex, economical, and rapid ;

The technical content of the mold is continuously improved, and the mold manufacturing cycle is continuously shortened. Mold production is developing in the direction of informatization, refinement and automation. The production level of China’s medical molds has made a qualitative leap compared to the previous ones. At the same time, production costs and labour costs are lower. China has become the world’s factory.

20. What is the development trend of China’s medical injection molding?

In China, the application of medical products, especially the development and application of high-end medical products, has only just begun and is a promising sunrise industry. The growth of medical products has not been affected by the financial crisis. At present, there is still a considerable gap between the technical level and consumption level of medical plastic products in my country and developed countries.

Therefore, improving the technical level and consumption level of China’s medical products is both an opportunity and a challenge for the development of my country’s medical injection molding products industry. Adhering to the scientific concept of development, taking the road of independent innovation, and striving to develop high-end medical components is the only way to achieve leapfrog development.

Leave A Comment