Knowing how to choose a large parts injection molding company is critical to quality but cost-effective plastic parts. Large parts injection molders know that injection molding of larger parts has different requirements.

The selected molding company must have suitable equipment that can handle high tonnage or can perform clamping forces of more than 500 tons. For any professional injection molded parts, you need to find an experienced company that can do the work for you.

However, choosing one can be a hassle, especially if you are just starting out. In addition to their machine capabilities, your manufacturer should be professional enough to meet your requirements and perform second-level technical needs.

Check out this checklist to see what to expect and look for from a large component injection molding company.

1. Ensure training and education

When choosing a large injection molding company, the first thing to pay attention to is whether they are qualified to provide services. The company should provide appropriate education and training for your needs.

Knowing what you expect from you, mastering all the machining manuals, and understanding other technical aspects of the job are the keys to successfully shaping the part. Ask the manufacturer whether he is always aware of the new trends and new technologies in the injection molding industry.

For example, part of proper injection molding training is basic knowledge of machine operation, equipment handling safety, part defect identification, and so on. Make sure their personnel, product engineers, machine operators, etc. are qualified to assist you in all these areas.

In this way, when they work with you in the raw material procurement and manufacturing phases themselves, you can be sure to get the best results.

2. See if the mold can keep up with the demand

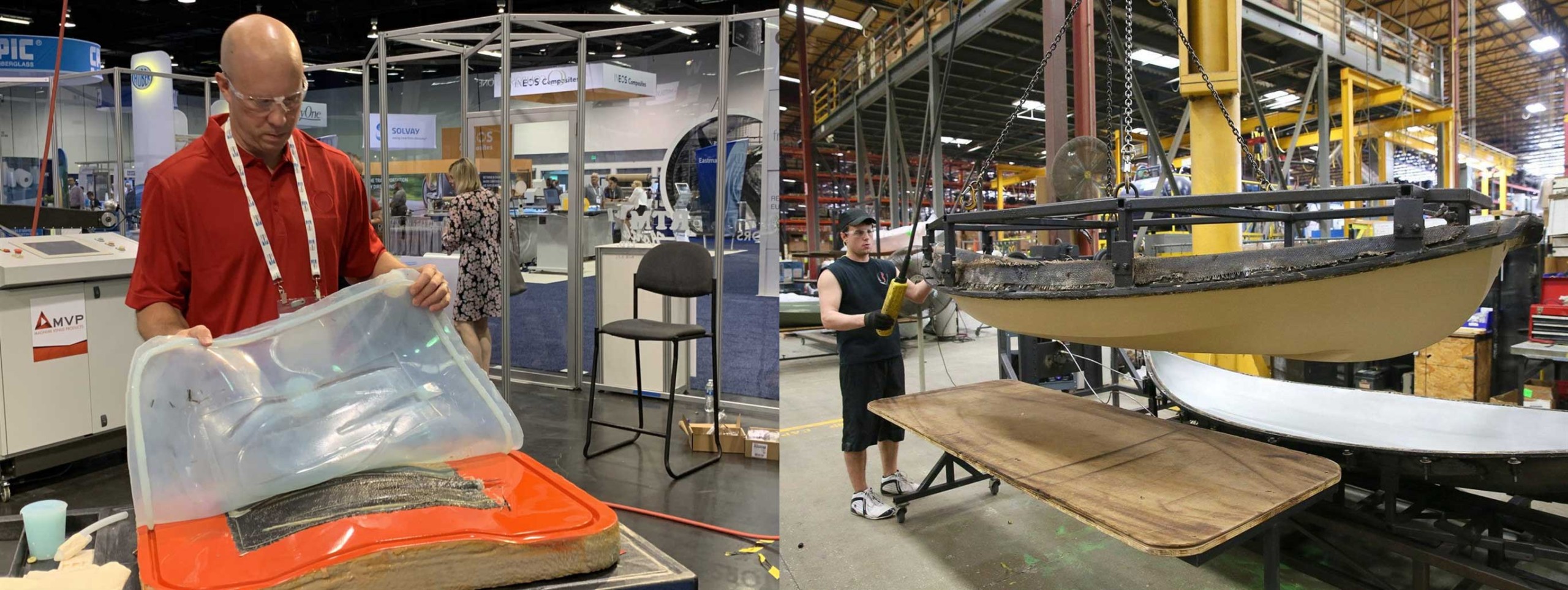

Manufacturing any large plastic product by injection molding always involves a rigorous process. Not only do mold makers need to have the right equipment at hand, but they should also be able to accommodate mass production of OEM and customized parts.

With this in mind, you need to find out that injection molds can keep up with your requirements as a company. When purchasing large parts and mold suppliers, ask if they can show you their factories or factories. This is a sure way to see what their process is in any day. It can also help you understand their business model and production capabilities.

Any professional large-scale molding company usually has an appropriate amount of machinery and mature technology to ensure that they can carry out mass production. This can help you determine whether they are suitable for your company’s processes.

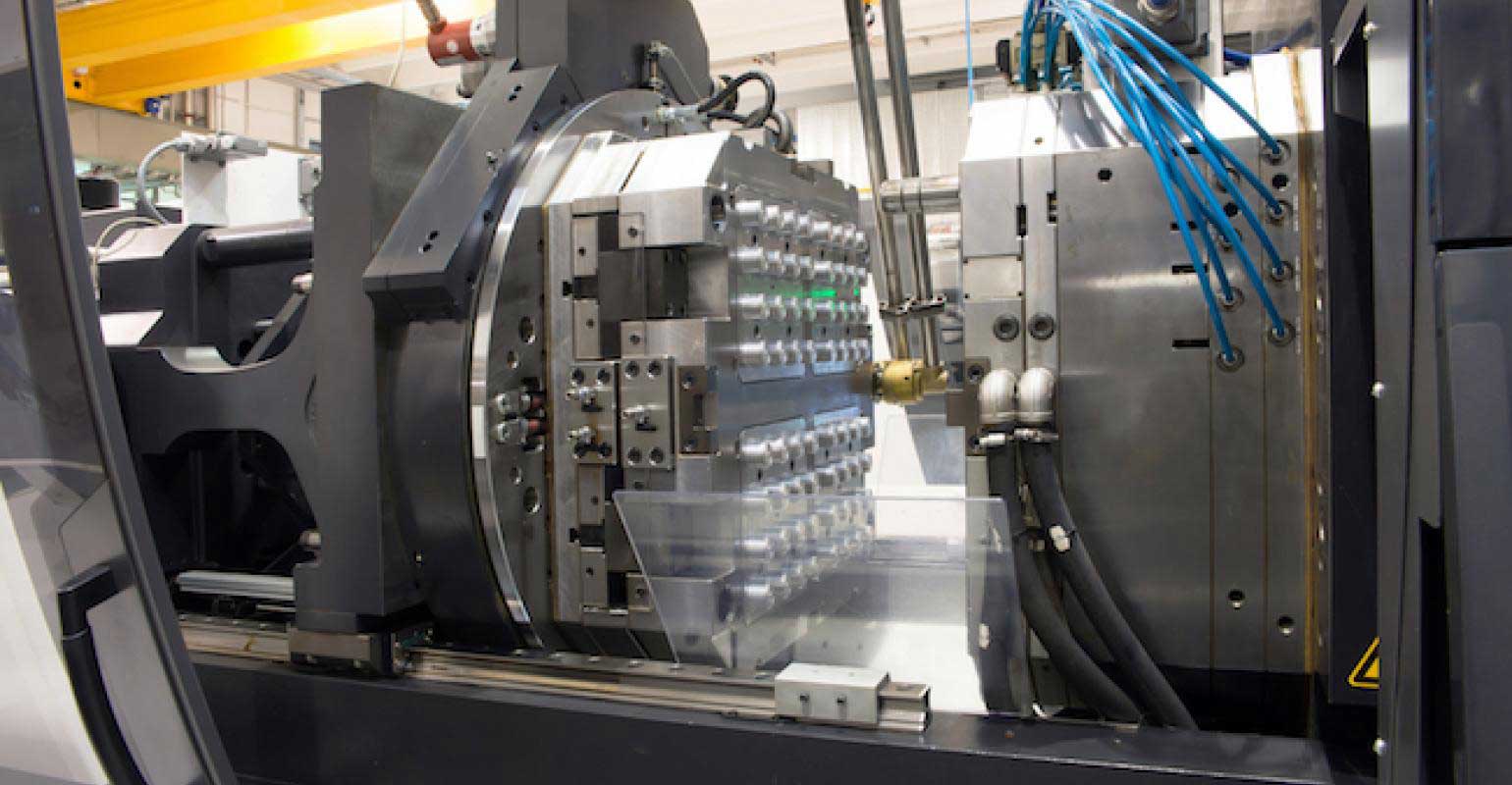

3. Know if they can perform other molding techniques

Although injection molding itself is already a complete process, it will ultimately depend on the requirements of the parts. Some plastic molded parts are also produced by other molding techniques that provide special functions.

There may be one or more of the following technologies: overmolding, insert injection molding, gas injection molding, thermoforming, hot runner and cold runner molding, and so on.

For example, overmolding involves using another plastic molded object to mold another material. This is similar to insert injection molding, where plastic parts are combined with metal inserts to facilitate subsequent assembly.

For any large part injection molding process, knowledge of these technologies is essential because they determine the integrity of the injection molding company’s operations. This also gives you more freedom to create various functional plastic prototypes to improve the quality of the final product.

4. Define your budget

As mentioned earlier, large-size plastic injection molding can be an expensive job because of the many requirements and processes required to perform this job. Knowing this, you should be able to clearly define a budget for you or your company to avoid excessive injection costs.

If you want your plastic parts to last longer and have other characteristics, then be prepared to allocate a lot of plastic parts for this effort. Likewise, don’t be tempted to choose a cheaper supplier. Sacrificing quality for cheap prices will almost always result in inferior parts and high costs for future repairs and maintenance.

5. Ensure they provide prototyping services

As part of the injection molding process, prototyping should always be done. This is the pre-production stage. It not only determines the buildability of the product but also determines the performance of the resin, the shrinkage rate and the formation of potential defects.

Prototyping services can ensure that any large-scale production of large parts can maintain its function and quality even after the 1000th cycle. Consider choosing a plastic molding company, capable of prototyping, CNC machining, rapid prototyping, etc. This ensures the consistency of plastic products, including size, quality, colour, durability, etc.

6. Conclusion

This checklist is about how to choose a large part forming company to give you an overview of what you will expect from the company you choose. To reiterate, forming large parts is not a simple process.

The plastic mold factory that provides this kind of service needs to understand the molding technology of large parts, the maintenance of high tonnage equipment, the implementation of other technologies, and so on.

In order to choose an injection molding company that satisfies all these requirements, the craftsmanship must be meticulous. Do all you have to choose high-quality and value-added large parts to find the right company.

Holly is a leading injection molding machine manufacturer, has been engaged in large-scale injection molding machines for decades. With our mature business model, prototyping service, customization and OEM product capabilities, we only guarantee high-quality manufacturing.

Leave A Comment