Short-run plastic injection molding is also known as small batch injection molding, this is a special process that uses aluminium or steel molds to create smaller batches of plastic products. The easy-to-think object (such as your child’s toy, or your TV remote) is just one of the millions of products created with this special operation every day.

There are many benefits of short-term injection molding, which we will discuss further in this article. These benefits are why plastic injection products are ubiquitous.

1. What are the Benefits of Short-term Injection Molding?

- Production working models and prototypes

- Rapid transformation

- Lower production cost

- Cost-effective

- Give the market more time

- Is it suitable for SMEs

2. Production working models and prototypes

Short cycle injection molding is faster than most other plastic production methods. This allows it to bridge the huge gap between the working prototype and the final product.

When the gap between these two stages shortens, the engineer has a working model that can be used in production and has enough time to adjust the design when needed.

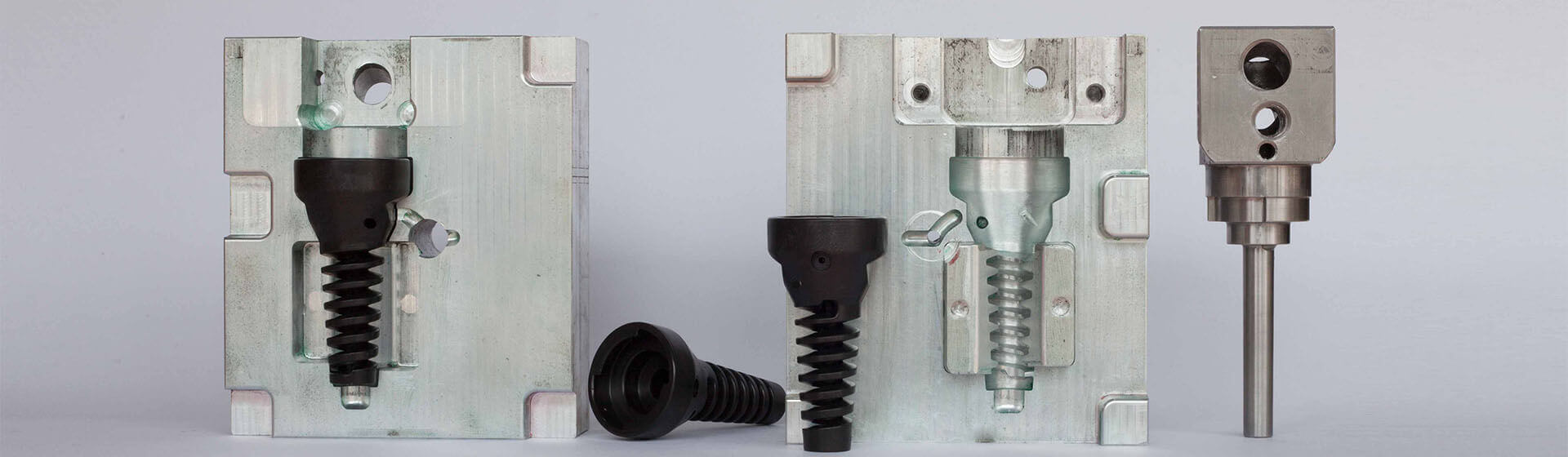

These working prototypes may also be more complex and detailed than you think. Plastic injection molding can easily create these complex designs. This is because this process uses an injection mold to make the plastic withstand higher pressure.

It is more precise than the shapes that are usually created by other methods due to the pressure created round the mold. When the plastic is manufactured by injection molding technology, its accuracy can reach within 0.001 inches.

3. Rapid Transformation

Compared with other plastic production methods, this method has a faster turnover rate. Its rapid production process can generate finished parts. These components can be sent to the customer (the person who ordered these components) and can be further assembled (if needed) to bring the product to the market faster.

At this speed, customers can reduce inventory in a shorter time while still meeting the market’s delivery requirements.

4. Lower Production Cost

Short-term injection molding can also reduce production costs. This is due to the high level of automation of the work and the use of cheaper mold materials (such as molds used in injection molding machines).

These materials are usually made of aluminium or low-grade steel, and despite their lower cost, they are still considered high-quality. Short-term injection molding can provide high-quality plastic parts and components while still having a competitive price.

In addition, this process can mold plastic parts in large quantities in a short period of time. This means that the investment time is the least, but the output ratio is high, which means that it is a very efficient system in terms of cost. This is one of the reasons why this molding technology reduces labour-the less time it takes to operate the machine, the less labour you pay.

The equipment in this process is also designed to reduce supervision. These machines can be completely controlled by a computer and can produce high-quality parts with a minimum of labour. The use of automated machines also reduces the chance of human error, thereby reducing the need to replace machines.

5. Cost-effective

Through this injection molding, the plastic parts come down from the mold and they have completed the appearance. The post-work of short-term injection molding is reduced, which also reduces the cost and makes the operation more efficient.

The actual production process is also very fast, especially when it comes to short-term runs. An injection molding machine can produce hundreds of identical parts from one mold, and this tool can be used for a long time before repairs or maintenance are needed.

Compared with other manufacturing processes, this technology generates very little waste. Any waste material can also be reground and recycled for future use.

Together with the aforementioned benefits, this ensures the creation of an economy, and small-scale quantities can be easily repeated on the basis of need. This allows customers to easily order parts when demand increases, even in a short time.

6. Give the Market More Time

Bringing your product to the market as soon as possible will greatly affect your company’s sales. Although the timing itself should not be too hasty, being the first choice in the market can create a huge advantage for you over your competitors.

Short-term injection molding can help your company put product ideas into production faster than other manufacturing processes. As mentioned earlier, it can create detailed prototypes and improve as production progresses.

Lower production runs and inexpensive molds can also speed prototype and concept testing, and allow sufficient feedback to be provided before the final product design is finalized.

This provides a huge time advantage, which is necessary for companies wishing to bring their products into emerging or volatile markets. By becoming one of the first choices in this market, these companies will be one step ahead of their competitors in providing the right solutions for the right customers.

7. Is it suitable for SMEs

The short-term operation of your product can save significant costs. For SMEs, this may be a life-saving straw, enabling them to compete with larger companies in the market.

Short-term plastic injection molding requires lower initial investment because they produce fewer products or parts, and can still create the high-quality designs and finishes that many companies are looking for.

Even when entering a smaller market, the cost and investment of creating the required products are still the biggest concerns for small businesses. Short-term injection molding can create the required small batches, and 100 or fewer units are still possible. Molds, programming and tools can also be outsourced to manufacturing companies, because many companies have rich professional experience in injection molding in different professional industries.

8. Conclusion

Short-term injection molding is widely used in today’s world for a reason, and the benefits mentioned above explain why this technology is so popular. One of the most effective and versatile manufacturing processes is injection molding.

Short-term plastic injection molding has many benefits, and this option may be the most suitable for your business and production needs. If you are looking for a manufacturer that can not only provide plastic injection molding services but also provide the right resources and expertise for your project, please contact Holly today!

Leave A Comment