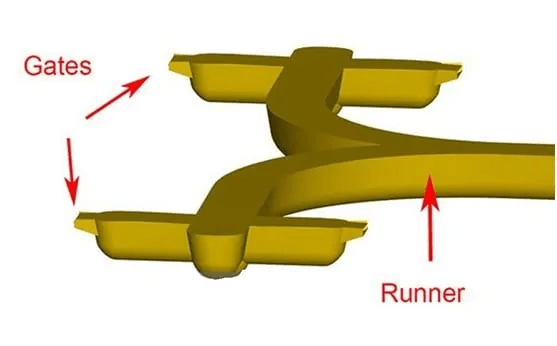

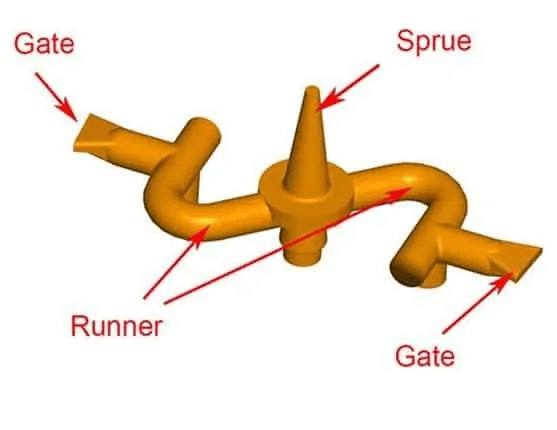

The runner and gate system (Links) used in the injection molding machine is responsible for guiding the molten plastic from the nozzle of the molding machine to the cavity of the mold.

The gate structure and its location will affect the cycle time of injection molded parts, mold cost, delivery date, witness mark location, and many other common potential defects.

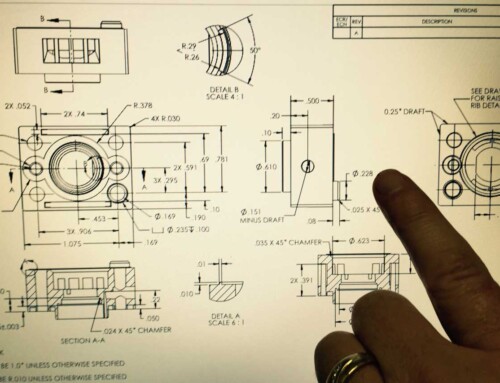

The following are the basic knowledge of gate design that every product developer should know. Having this information will help you make informed decisions when negotiating with suppliers to make injection mold tools. Holly inspects plastic injection mold tools before installation.

1. Importance of Gate Location

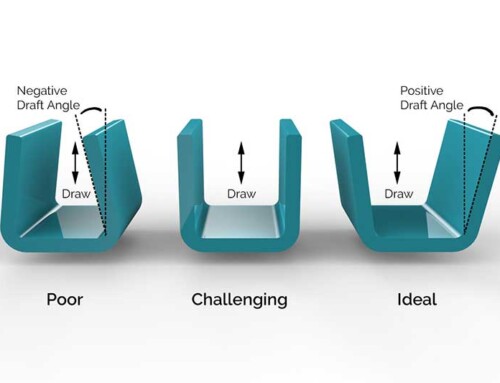

The location of the gate directly affects the quality of the finished product, so please consider the following general rules:

- The gate should be placed away from pins, iron cores and other internal obstacles. Otherwise, this may cause welding marks because the molten plastic flows around and on the other side of the reform

- The gate should be placed closest to the thick-walled area to ensure complete packaging

- Improper gate position will cause partial deformation, if the entire part of the build volume is not uniformly filled

- The gate is an area of high pressure. Try to place the gate far away from the finished part, these places will be affected by stress marks or potential degradation of the plastic

- The gate needs to be located in an area that is easy to drain manually or automatically. Please note that some plastics are susceptible to high shear forces, so the gate can only be unloaded manually

- Thin-walled parts may require flow channels or additional gates to provide sufficient plastic volume in the shortest cycle

2. Gate Design will Affect Part Quality

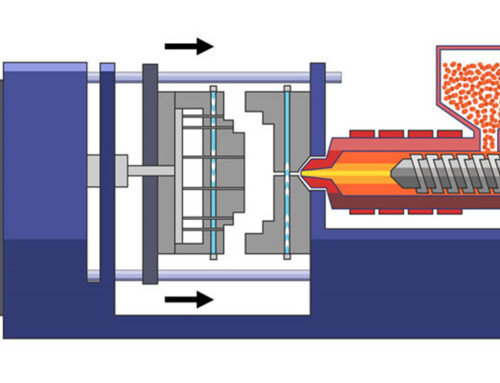

All gates force the molten plastic into the cavity under pressure, and the cavity accelerates and heats the plastic. This has produced various effects that may require changes to the gate design strategy.

The most common defects include:

1) Injection

If the gate is too small, the pressure drop across the gate will cause jetting, that is, jetting into the cavity instead of flowing smoothly. The jet causes wave deformation, which is called “creeping”. This may require reducing the pressure, increasing the gate, or both.

2) Overheat

The high jet velocity through the gate generates heat through friction. At this point, excessive heat will break the molecular bonds and cause the resin to rot. However, slowing down the injection speed to avoid degradation may lead to other defects, such as poor mechanical strength at the weak weld.

Furthermore, more parts per hour are produced at a lower cycle time, which increases processing costs. Therefore, it is possible to divide a given volume of resin into several individual gate holes.

This helps to dissipate pressure and avoid overheating, but it also creates multiple flow fronts, which can lead to weld lines and gas traps, which meet in the cavity.

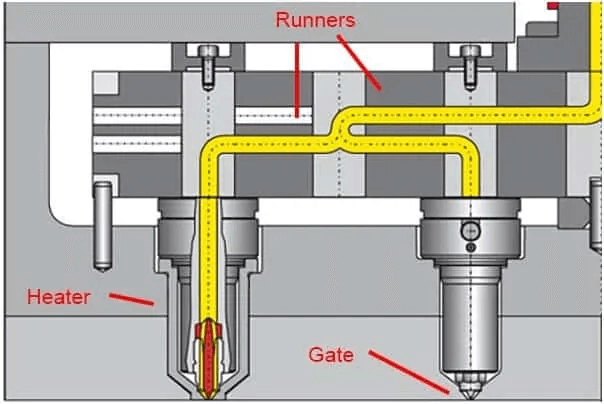

3. The difference between hot runner system and cold runner system

1) Hot runner

The hot gate/runner system uses an electrically heated cylinder to deliver the preheated plastic to the mold cavity. Molds have a manifold plate and hot runner drops built into them as the runner. Typical hot runner system for plastic injection mold.

Advantage:

- Precise temperature control to achieve a better appearance

- Eliminate waste of multi-cavity tools

- Reduce cycle time

Disadvantages:

- More complicated and expensive

2) Cold Runner

The cold runner system is cheaper, but the length of the runner represents the plastic, which is wasted in each cycle, which in turn increases the cost. Moving the witness mark to a more favorable position should be balanced with the increased material consumption due to long-distance running.

4. Pros and cons of the most common gate types

There are different sizes and shapes of gates to consider, and each has trade-offs. The following are the most common ones:

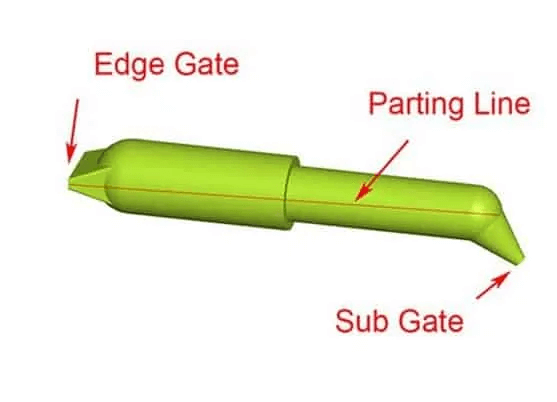

1) Edge Gates

Edge gates are the most commonly used. They are processed into the mold on the parting line, filling the cavity from the side of the part. Edge gates are usually used for flat, thin parts.

Advantage:

- Low design and manufacturing costs

- If necessary, zoom in without removing the mold from the machine

Disadvantage:

- The location of witness marks may not be ideal

- When plastic flows from a single gate, it will produce obvious welds when flowing around obstacles in the mold

The high injection pressure and speed at the small gateway will cause the plastic to degrade

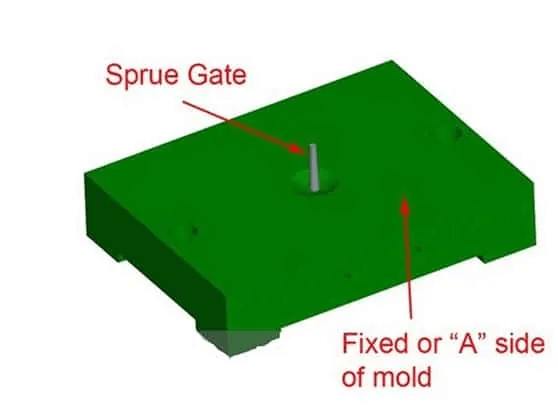

2) Direct or Sprue Gate

Go directly to the gate on the fixed surface of the tool or on the A surface. The gate is embedded in the fixed half of the injection mold tool.

Advantage:

- The easiest gate to make

- Able to inject large amounts of plastic quickly

- Suitable for round or cylindrical parts where concentricity is important

Disadvantage:

- Leave a huge witness mark on the other side, which may become a sink mark

- Must go to the gate manually

3) Submarine Gate

The runner guides the plastic to the edge of the cavity of the parting line, and then the gate drops below the parting line and tunnels upward to fill the part from below. A double-plate mold structure is the only one suitable for this design The underwater gate fills the cavity from below the parting line.

Advantage:

- Move the witness mark to a more ideal location

- Excess exhaust gas can be pushed upward from the bottom of the mold

- Automatically unload the mold when the mold is opened

Disadvantage:

- It is more complicated, more expensive and time-consuming to manufacture

4) Fan Gate

As another type of edge gate, the fan maintains the same thickness but extends to a larger area to increase the volume. Recommended for polycarbonate plastics. Fan gate helps to eliminate injection stress.

Advantage:

- Conducive to increase the flow of thin-edged parts

- Reduce the injection pressure under a given volume

Disadvantage:

- It may leave a large witness mark with the same label, which must be post-processed

Are you ready to start the next project?

The above is just a summary of several considerations for plastic injection molding gate design. If you are ready to start your next tool making project, upload your 2D/ 3D CAD design for a free quote, our team of engineers and technicians can provide you with a manufacturing review design before we start making mold tools.

Leave A Comment